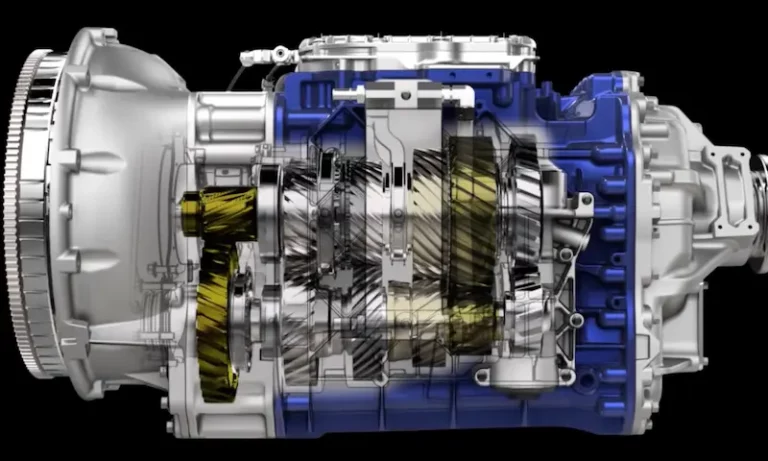

Ever noticed your Volvo truck shifting oddly or heard strange noises when changing gears? You’re dealing with one of the most sophisticated automated manual transmissions on the market – the Volvo I-Shift. While this innovative system can boost fuel efficiency by up to 10%, it’s not without its quirks.

1. Gear Slipping During Operation

Gear slipping is probably the most frustrating I-Shift issue you’ll face. You’re accelerating or hauling a heavy load when suddenly the transmission pops out of gear.

Several culprits are typically to blame:

- Faulty clutch actuator components – When the clutch actuator malfunctions, it can’t properly engage or disengage the clutch. The clutch actuator solenoid often wears out, preventing proper hydraulic fluid flow.

- TECU failures – The Transmission Electronic Control Unit is basically the brain of your I-Shift. When it fails, expect erratic shifting patterns and gear slipping.

- Sensor issues – Your I-Shift relies on numerous sensors to determine shifting timing. Bad sensor data equals bad shifting decisions.

- Low fluid levels – Check your transmission fluid! Low levels create insufficient hydraulic pressure, making proper shifting impossible.

Early I-Shift models (mid-2000s to early 2010s) were particularly notorious for what drivers called “crazy clutch wear” because they’d select overly high starting gears and engage in excessive clutch slipping.

2. Hard or Jerky Shifting

Does your truck lurch forward violently when accelerating from a stop? That jerky shifting is a common I-Shift complaint that can make driving uncomfortable and potentially damage your transmission over time.

The main causes include:

- Brake switch calibration problems – According to Volvo technical bulletins, the brake pedal switch and pressure switch should operate between 2-6 psi ascending pressure. When improperly calibrated, you’ll get harsh acceleration from stops.

- Clutch control actuator wear – A damaged or worn clutch control actuator directly impacts shift quality, creating those bone-jarring gear changes.

- Software adaptation issues – The I-Shift continually learns and adapts to your driving style. Sometimes it learns bad habits, leading to deteriorating shift quality over time.

You’ll typically notice jerky shifting most when starting from a complete stop or when downshifting under load.

3. Transmission Lockup and Complete Failure to Shift

This is the nightmare scenario – you’re on the road and suddenly your transmission refuses to shift at all. A completely locked-up I-Shift can be caused by:

- Blown fuses – A 2019 safety recall (RVXX1903) affected approximately 235 Volvo trucks (2018-2020 VAH, VHD, VNL, and VNR models) due to fuses in the transmission circuit blowing and preventing shifting.

- Electrical relay failures – The relays under your dashboard are critical for transmission operation. Many drivers report that replacing power relays and the gearbox relay is an effective preventative measure.

- Moisture intrusion – Water entering electrical connections, particularly the I-Shift plug near the driver’s seat, can completely disable shifting functionality.

- Air leaks – Leaks in the transmission system can cause erratic shifting as air bleeds to incorrect destinations within the system.

4. Overheating Issues

Your I-Shift transmission can overheat under certain conditions, triggering protective “limp mode” to prevent damage:

- Extended heavy loads – Hauling maximum weight for long periods strains the transmission cooling system.

- Cooling system problems – Insufficient cooling or degraded transmission fluid reduces heat dissipation capacity.

The I-Shift features selectable transmission oil cooling programs to adjust cooling based on operating conditions, but these can fail or become less effective over time.

5. Electronic Control System Failures

The sophisticated electronics controlling your I-Shift can develop various problems:

- TECU malfunctions – The Transmission Electronic Control Unit can fail completely or develop glitches that cause erratic shifting.

- Corrupted software – Software issues can develop over time, affecting transmission performance.

- Sensor failures – Input shaft speed sensors, output shaft speed sensors, and various pressure sensors can all fail individually.

These electronic issues often manifest as inconsistent shifting patterns, incorrect gear selection for conditions, or warning lights on your dashboard.

6. Clutch System Problems

The I-Shift’s clutch system can develop several distinct issues:

- Excessive clutch wear – Earlier I-Shift models were particularly prone to premature clutch wear due to software selecting inappropriate starting gears.

- Clutch actuator failures – The actuator that controls clutch engagement can develop mechanical or hydraulic problems.

- Oil contamination – Contaminated transmission fluid can damage clutch components.

Symptoms typically include slipping, difficulty starting from a stop, and burning smells during operation.

7. Air System Leakage Issues

The I-Shift relies on pressurized air for many operations, and air system problems can cause significant issues:

- Internal air leaks – Leaks from the shift control housing may require replacement of housing assembly or internal components like shift forks or pistons.

- External air line damage – Damaged air lines can prevent proper pressure from reaching transmission components.

- Air control valve failures – The valves controlling air flow can stick or fail.

Air system issues often create intermittent problems that are difficult to diagnose since they may only occur during specific shifting operations.

How to Reset Your Volvo I-Shift Transmission

For minor issues, a transmission reset can often resolve problems and improve performance. Here’s the general process:

- Stop the vehicle completely and turn off the ignition

- Locate the service button (typically near the control panel)

- Press and hold the button for about five seconds until a prompt appears

- Navigate to the reset option using the select button

- Restart the truck and allow the system to apply new settings

This reset can resolve many common electronic glitches without a trip to the service center.

Preventative Maintenance to Avoid I-Shift Problems

Regular maintenance can prevent many I-Shift problems before they occur:

Fluid Maintenance Schedule

The I-Shift AT2612 has extended maintenance intervals with oil and filter changes recommended:

- Every 450,000 km (280,000 miles) maximum

- Or every third year, whichever comes first

Electrical System Care

Prevention is much cheaper than repair when it comes to electrical issues:

- Regularly inspect batteries and connections

- Make sure all ground straps are secure and clean

- Keep the I-Shift plug near the driver’s seat protected from moisture

- Some drivers place a towel in this area to absorb any spilled liquids

Software Updates

Keep your I-Shift’s software updated:

- Regular updates improve functionality

- Updates often address known issues before they affect performance

- Many dealerships offer software update services

Quick Inspection Checklist

| Maintenance Task | Frequency | What to Look For |

|---|---|---|

| Check transmission fluid | Weekly | Proper level, clear color, no metal particles |

| Inspect electrical connections | Monthly | Corrosion, loose connections, damage |

| Listen for air leaks | Daily | Hissing sounds, especially during shifting |

| Check warning lights | Before each trip | Any transmission-related warnings |

| Inspect mounting hardware | Every service interval | Loose bolts, cracks in mounting brackets |

When to Call a Professional Mechanic

While some issues can be addressed by operators, others require professional intervention:

- Persistent warning lights after a reset likely indicate deeper mechanical problems

- Mechanical noises like grinding or loud clunks require immediate professional attention

- Visible fluid leaks can’t be resolved by resetting and need repair to prevent severe damage

- Frequent overheating may indicate cooling system problems requiring specialized diagnosis

- Complete failure to shift after attempting basic troubleshooting needs professional repair

Evolution of the I-Shift System

The I-Shift has undergone significant improvements since its 2001 introduction:

| Generation | Year Introduced | Key Improvements |

|---|---|---|

| First Gen | 2001 | Original electronically controlled shifting for long-haul transport |

| Second Gen | ~2005 | Redesigned clutch system and range-change unit for higher GCW |

| Third Gen | ~2010 | Added customized software options for demanding applications |

| Current Gen (G+) | ~2015 | Faster and smoother gear changing, improved computational capacity |

Newer models feature improved software accuracy, more powerful control units, and enhanced adaptability to different driving conditions.

The Volvo I-Shift technology has matured significantly over the years. While it’s not immune to problems, understanding these common issues and their solutions will help keep your truck on the road where it belongs. With proper maintenance, your I-Shift transmission can provide years of reliable service and the fuel efficiency benefits it was designed to deliver.