Looking for reliable information about the Caterpillar 3126 engine? Whether you’re maintaining a commercial truck, upgrading a marine vessel, or simply need to understand this versatile powerplant for work purposes, you’re in the right place. This comprehensive guide breaks down everything from basic specifications to performance variations across all 3126 models.

What Is the Caterpillar 3126 Engine?

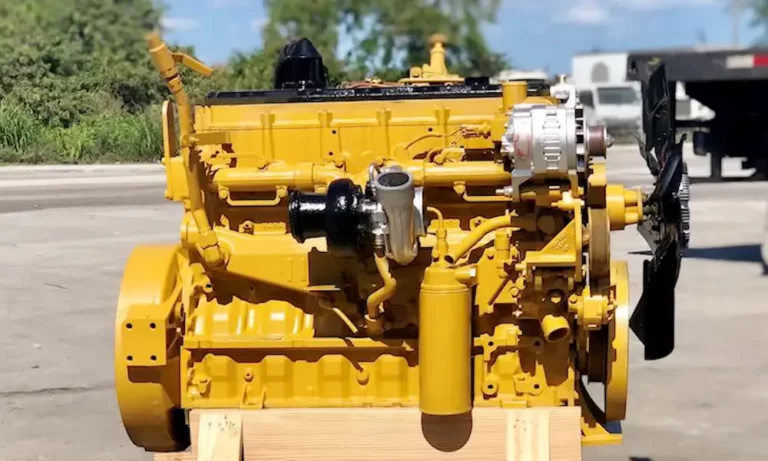

The Caterpillar 3126 is a 7.2-liter inline-six medium-duty diesel engine that revolutionized the industry when it launched in 1995. As Cat’s first electronic mid-range diesel engine, it replaced the 3116 series and served as a pivotal transition model in Caterpillar’s evolution toward more sophisticated engine management systems.

With a production run until the mid-2000s (before being succeeded by the C7 in 2003), the 3126 established itself as an incredibly versatile performer, powering everything from dump trucks and ambulances to buses, recreational vehicles, and marine vessels. Its adaptability across diverse operational environments speaks to the fundamental engineering excellence behind its design.

Core CAT 3126 Engine Specifications

Basic Engine Configuration

The 3126 features a straightforward yet robust design that provides the foundation for its reliability:

| Specification | Measurement |

|---|---|

| Engine Type | Inline 6-cylinder, 4-stroke diesel |

| Displacement | 7.2 liters (442 cubic inches) |

| Bore | 110 mm (4.33 inches) |

| Stroke | 127 mm (5.0 inches) |

| Compression Ratio | 16:1 to 17.25:1 (varies by model) |

| Aspiration | Turbocharged (with aftercooling in many variants) |

| Rotation | Counterclockwise (viewed from flywheel end) |

| Weight | Approximately 568-722 kg (1250-1592 lbs) |

The engine’s inline-six configuration provides excellent balance and smoother operation compared to some other designs, while the robust displacement delivers the torque needed for demanding applications.

Physical Dimensions

When planning an installation or replacement, physical dimensions become critical. The 3126 varies slightly across applications:

| Dimension | Measurement Range |

|---|---|

| Length | 42.5-46.7 inches (1078-1184 mm) |

| Width | 26.5-36.9 inches (673-937 mm) |

| Height | 34.0-36.5 inches (862-927 mm) |

Marine applications typically run toward the larger end of these ranges, with marine variants measuring 46.7 inches (1183.9 mm) in length, 35.7 inches (905.6 mm) in height, and 36.9 inches (937 mm) in width.

Major 3126 Engine Variants and Their Applications

Throughout its production, Caterpillar released several significant variants of the 3126 engine, each tailored to specific needs and applications.

CAT 3126B

Introduced in 1998, the 3126B represented a major upgrade to the original platform:

- Power range: 175-300 hp

- Applications: Trucks, buses, passenger vehicles, marine vessels, and generators

- Key features: Introduced the groundbreaking HEUI (Hydraulically actuated Electronically controlled Unit Injector) fuel system and ADEM III electronic control system

- Emissions standards: Met EPA Tier 2 and EU Stage II requirements

The HEUI system marked a significant advancement in diesel technology, allowing much more precise fuel delivery control while simultaneously improving emissions performance.

CAT 3126E

Launched in 2002, the 3126E represented the final evolution of this engine platform before transitioning to the C7:

- Power range: 175-420 hp

- Applications: Similar to 3126B, with enhanced capabilities

- Improvements: Advanced electronic engine management systems that delivered better power characteristics and improved fuel efficiency

- Production: Manufactured until 2003 when the C7 took its place

The “E” designation signified the enhanced electronic controls that defined this variant, making it the most sophisticated 3126 model produced.

Performance Specifications Across Applications

One of the 3126’s greatest strengths was its adaptability across widely varying applications. Let’s examine how its performance translated across different use cases.

Truck and Bus Applications

In commercial transportation, the 3126 delivered a balance of power, durability, and operational efficiency:

- Power range: 170-300 hp for most truck applications

- Common configurations:

- 175 hp (131 kW) with 420 lb-ft (569 N-m) peak torque at 1440 rpm

- 190 hp (142 kW) with 520 lb-ft (705 N-m) peak torque at 1440 rpm

- 300 hp for heavier-duty applications like dump trucks and cement mixers

- Operational parameters:

- Typical operating range: 1440-2500 rpm

- Maximum engine speed: 2640 rpm

- Governed speed: 2500 rpm

- Torque rise: 25-27% depending on configuration

- Altitude capability: Up to 10,000 ft (3050 m)

The engine’s considerable torque at low RPM made it ideal for applications requiring strong pulling power, like buses and delivery trucks.

Marine Applications

In marine settings, the 3126 was renowned for its reliability—a critical factor when you’re miles from shore:

- Maximum power: Up to 350 bhp (261 kW) at 2800 rpm in propulsion configurations

- Special marine features:

- Heat exchanger cooling

- Watercooled exhaust manifold and turbocharger

- Gear-driven auxiliary sea water pump

- Belt-driven centrifugal jacket water pump

- Rating classification: E Rating (Maximum Continuous), designed for vessels operating at rated load and rated speed up to 8% of the time

- Maintenance intervals: 250-hour oil change interval for marine applications

The marine variants included specific adaptations to handle the harsh saltwater environment and provide the reliability that boat owners demand.

Industrial Applications

When used in industrial equipment, the 3126 delivered consistent performance in demanding conditions:

- Power range: 175-300 hp

- Applications: Construction equipment, generators, compressors, and other stationary power needs

- Variants: Both 3126B and 3126E configurations were available with application-specific tuning

- Durability: Designed for extended operation in harsh environments with high dust, temperature variations, and constant load

The industrial variants were often customized with specific governor settings and cooling packages to match particular applications.

Advanced Features and Technologies

What truly set the 3126 apart from many contemporaries was its integration of advanced technologies that enhanced performance, reliability, and adaptability.

HEUI Fuel System

The Hydraulically actuated Electronically controlled Unit Injector system represented a significant technological leap:

- Eliminated the need for traditional injection pumps

- Provided precise control of injection timing and duration

- Allowed for multiple injection events per cycle

- Improved cold-start capabilities

- Enhanced fuel economy

- Reduced emissions without sacrificing performance

This innovative system used engine oil pressure to activate fuel injectors while electronic controls managed timing and duration, a considerable improvement over purely mechanical systems.

Engine Control Features

The 3126B included three distinctive control features that gave operators and manufacturers flexibility:

- Torque Limiting Feature: Allowed torque to be limited to selected values across the operating range via a switch input to the electronic control module

- Top Engine Limit (TEL): Limited speed along the engine lug curve, enabling rating flexibility without requiring special calibrations

- Power Trim: Permitted OEMs to adjust the power curve vertically between -3 and +3 percent relative to speed

These features made the 3126 highly adaptable to specific operational needs without requiring extensive reconfiguration.

Emissions Compliance

When introduced, the 3126 met the increasingly stringent emissions regulations of its era:

- Complied with EPA Tier 2 and EU Stage II emissions standards

- Utilized advanced electronic controls to optimize combustion

- Incorporated precision fuel injection for reduced particulate matter

- Managed air-fuel ratios to control NOx emissions

These compliance measures made the 3126 a forward-looking design that helped fleet operators meet environmental requirements without sacrificing performance.

Common Issues and Maintenance Considerations

Despite its reliability, the 3126 has several known issues that owners should monitor:

HEUI System Challenges

While innovative, the HEUI system can present specific problems:

- Injector failures can occur at high mileage (typically 200,000+ miles)

- The high-pressure oil pump may require replacement around 300,000 miles

- Oil quality becomes extremely important since it drives the injection system

- Regular oil and filter changes are critical to system longevity

To maintain HEUI system health, use only CAT-approved oils and follow maintenance intervals strictly.

Cooling System Maintenance

The 3126 works hard and generates significant heat:

- Cooling system capacity must be maintained

- Water pump failures are not uncommon after extended service

- Thermostats should be replaced at regular intervals

- Radiator flow must be unrestricted

Preventative maintenance of the cooling system can help avoid catastrophic overheating events.

Oil Consumption Considerations

Some 3126 engines develop increased oil consumption with age:

- Monitor oil levels regularly

- Check for leaks around valve covers and oil cooler lines

- Valve seals may deteriorate over time

- Crankcase ventilation system should be kept clean and functional

Addressing oil consumption early can prevent more serious issues from developing.

Comparison with Predecessor and Successor Models

Understanding how the 3126 fits into Caterpillar’s engine evolution provides valuable context:

3126 vs. 3116

The 3126 offered significant improvements over its predecessor:

- Increased displacement (7.2L vs. 6.6L)

- Enhanced electronic controls

- Better fuel efficiency

- Improved power density

- More sophisticated emissions controls

- Broader application flexibility

These improvements made the 3126 a clear advancement over the mechanically-focused 3116.

3126 vs. C7

When the C7 replaced the 3126 in 2003, it brought additional refinements:

- Enhanced ACERT (Advanced Combustion Emission Reduction Technology)

- Improved emissions performance meeting EPA Tier 3 standards

- More robust internal components

- Enhanced electronic diagnostic capabilities

- Better fuel economy

- Smoother power delivery

The C7 built upon the 3126’s successful foundation while incorporating new technologies to meet stricter emissions requirements.

Rebuilding and Overhaul Information

For owners considering rebuilding their 3126 engine:

Typical Rebuild Intervals

- Highway applications: 500,000-700,000 miles with proper maintenance

- Marine applications: 10,000-12,000 hours

- Industrial applications: Varies widely based on duty cycle

Common Rebuild Requirements

- Main bearings and connecting rod bearings

- Piston rings and possibly pistons

- Cylinder liners (if worn beyond specification)

- Valve guides and seats

- Injectors (typically replaced rather than rebuilt)

- Oil and water pumps

- Gaskets and seals throughout

A quality rebuild with genuine Caterpillar parts can extend engine life significantly and restore original performance levels.

Performance Upgrade Opportunities

During rebuilds, some performance enhancements may be possible:

- Upgraded turbocharger options

- Enhanced cooling system components

- Improved electronic calibrations (where applicable)

- Higher-flow injectors (within design parameters)

Any modifications should be carefully evaluated for compatibility with the engine’s intended application and duty cycle.

Purchasing Considerations for Used 3126 Engines

If you’re in the market for a used 3126 engine:

Critical Inspection Points

- Check for excessive blowby (exhaust gases escaping past the piston rings)

- Inspect oil for metal particles or contamination

- Review maintenance records if available

- Check for coolant intrusion into oil

- Evaluate injector performance through diagnostic testing

- Inspect the turbocharger for shaft play and oil leaks

- Look for evidence of overheating

Serial Number Significance

The 3126’s serial number provides valuable information:

- Location: Stamped on the engine block

- Format: Typically begins with “7AS” or “8YL”

- Significance: Indicates manufacturing date, specifications, and original application

Always verify the serial number against Caterpillar’s database to confirm the exact engine configuration.

Replacement Cost Considerations

When evaluating whether to replace or rebuild:

- New replacement (C7): $20,000-$25,000+ depending on configuration

- Remanufactured 3126: $12,000-$18,000

- Quality rebuild: $8,000-$15,000 depending on parts replaced

- Used 3126 with unknown history: $4,000-$8,000 (higher risk)

Compare these costs against the expected remaining service life needed for your application.

The 3126 Legacy in Heavy-Duty Applications

The Caterpillar 3126 earned its place in diesel engine history through its versatility and reliability. From powering school buses that safely transported generations of children to propelling commercial fishing vessels through rough seas, it proved itself across countless applications.

While newer models have replaced it in production, thousands of 3126 engines remain in service worldwide—testament to the fundamental soundness of its design and construction. For many operators, the 3126 represents an ideal balance of technological advancement and straightforward serviceability that newer, more complex engines sometimes lack.

For those maintaining or operating equipment powered by the 3126, understanding its specifications and characteristics is essential to maximizing its potential and extending its service life. With proper care and maintenance, these engines can continue delivering reliable performance for many years to come.