Ever wondered why some cars stop on a dime while others feel like they need a runway? The secret might be in your brake booster system. Whether you’re upgrading your project car or just curious about what’s under your hood, understanding the difference between hydroboost and vacuum boost systems can save you headaches (and potentially your life). Let’s dive into these two braking technologies and help you figure out which one belongs in your vehicle.

What Are Brake Boosters and Why Do You Need One?

Brake boosters do exactly what their name suggests – they boost the force you apply to your brake pedal. Without them, you’d need thighs of steel to stop your vehicle effectively.

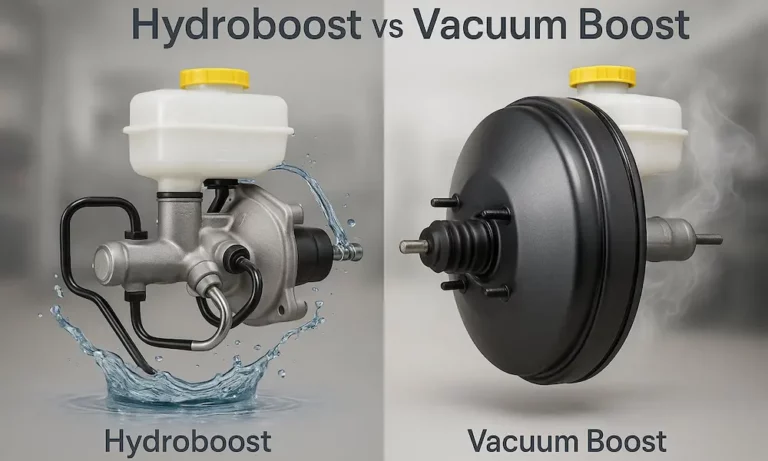

These systems multiply your pedal pressure before it reaches the master cylinder, making braking effortless even in heavy vehicles. There are two main types in today’s vehicles: vacuum boost (the traditional option) and hydroboost (the hydraulic alternative).

How Vacuum Boost Systems Work

Vacuum boosters are the OG of power brake systems and still dominate the automotive landscape. They’re those large round canisters mounted between your brake pedal and master cylinder.

The Basic Mechanism

A vacuum booster uses the pressure difference between engine vacuum and atmospheric pressure to amplify your braking force. When you press the brake pedal, a valve opens, allowing atmospheric air to flow into one side of a diaphragm while the other side maintains vacuum. This pressure differential creates force that helps push the master cylinder piston.

The system draws vacuum from your engine’s intake manifold, where negative pressure naturally occurs during operation. This elegant simplicity is why vacuum boosters have been the industry standard for decades.

Vacuum Boost Advantages

✅ Cost-effective ($100-$200 for most applications)

✅ Simple design with fewer components to fail

✅ Easy to install and maintain

✅ Smooth, progressive pedal feel that many drivers prefer

✅ Works well with most stock engines

How Hydroboost Systems Work

Hydroboost systems take a completely different approach to brake assistance by harnessing hydraulic pressure instead of vacuum.

The Hydraulic Advantage

Instead of relying on engine vacuum, hydroboost systems tap into your vehicle’s power steering pump for hydraulic pressure. When you hit the brakes, this pressurized fluid (up to 2,000-2,500 psi) flows into the booster unit, dramatically amplifying your pedal force.

One key component is the accumulator – a pressure storage device that provides backup braking assistance if your engine stalls or the power steering pump fails. This safety feature ensures you’ll have several brake applications available even without engine power.

Hydroboost Advantages

✅ Consistent braking power regardless of engine vacuum

✅ More powerful assistance (up to 2,500 psi vs. 800-1,400 psi for vacuum)

✅ Compact design that fits in tight engine bays

✅ Performs well with modified engines (turbos, superchargers, big cams)

✅ Excellent for heavy vehicles and towing applications

Performance Comparison: Pedal Feel and Stopping Power

When it comes to actual braking performance, the differences between these systems become more apparent.

Braking Force

Vacuum boosters provide adequate assistance for vehicles up to about 3,400 pounds under normal driving conditions. However, they have a significant weakness: their performance diminishes when engine vacuum is low – like during hard acceleration, at high RPMs, or with performance camshafts.

Hydroboost systems deliver consistent, powerful assist regardless of engine condition. They provide instant response with minimal pedal travel, creating a firmer pedal feel that performance drivers often prefer. The braking force remains stable whether you’re cruising or flooring it.

Real-World Feel

Here’s how the pedal feel typically compares:

| Characteristic | Vacuum Boost | Hydroboost |

|---|---|---|

| Initial feel | Soft, progressive | Firm, responsive |

| Pedal travel | Longer | Shorter |

| Consistency | Varies with vacuum | Consistent regardless of conditions |

| Feedback | More cushioned | More direct |

Reliability and Maintenance Requirements

No braking system is maintenance-free, but there are significant differences in what you can expect.

Vacuum System Maintenance

Vacuum boosters are relatively simple devices. Common maintenance issues include:

- Check valve failures causing loss of vacuum

- Vacuum hose deterioration or leaks

- Diaphragm wear or failure over time

When they fail, the symptoms are usually gradual – increasingly hard pedal feel, longer stopping distances, and sometimes a hissing sound. Replacement is straightforward and relatively affordable.

Hydroboost System Maintenance

Hydroboost systems introduce more complexity:

- Requires regular power steering fluid checks

- Additional hydraulic lines that could leak

- Power steering pump that works harder (serving both steering and brakes)

The hydroboost unit itself is actually quite reliable, but the system depends on proper power steering function. When issues arise, diagnosis can be more complicated than with vacuum systems. However, these systems are less prone to vacuum-related failures that plague traditional boosters.

Installation and Packaging Considerations

The physical differences between these systems create distinct installation challenges.

Space Requirements

Vacuum boosters are bulky – those large canisters can create clearance issues with valve covers, headers, or other engine components. This is especially problematic in engine swaps or vehicles with limited firewall space.

Hydroboost units are significantly more compact, often half the size of their vacuum counterparts. This smaller footprint makes them ideal for tight engine bays or vehicles with big engines crammed into small spaces.

Installation Complexity

Installing a vacuum booster is generally straightforward:

- Mount the booster to the firewall

- Connect the vacuum line to the intake manifold

- Connect the pushrod to the master cylinder

Hydroboost installation involves more steps:

- Mount the hydroboost unit

- Connect to the power steering system with high-pressure hoses

- Add proper fluid reservoirs and return lines

- Ensure proper fluid routing to prevent pump cavitation

The hydroboost installation is more involved and typically costs more, with quality installation kits running $500-$1,200 compared to $100-$200 for vacuum systems.

Cost Analysis: Initial Investment vs. Long-Term Value

Your budget plays a major role in deciding between these systems.

Upfront Costs

Vacuum boosters are the budget-friendly option:

- Basic vacuum booster: $100-$200

- Auxiliary vacuum pump (if needed): $300-$400

- Installation parts: $50-$100

Hydroboost systems demand a bigger investment:

- Complete hydroboost kit: $700-$900

- Quality hydraulic lines and fittings: $100-$300

- Additional fluid and reservoirs: $50-$100

Long-Term Value

While hydroboost systems cost more initially, they can provide better value in certain situations:

- Vehicles with modified engines that struggle with vacuum

- Applications where consistent braking is critical (towing, heavy loads)

- Cars where the compact size enables otherwise impossible engine swaps

Which System Is Right for Your Vehicle?

The ideal braking system depends on your specific vehicle and how you use it.

Choose Vacuum Boost If:

- You have a stock or mildly modified naturally aspirated engine

- You’re on a tight budget

- You prefer a softer, more progressive pedal feel

- You’re restoring a vehicle to factory specifications

- Your vehicle weighs under 3,500 pounds

Choose Hydroboost If:

- Your engine produces limited vacuum (turbo, supercharged, aggressive cams)

- You need compact packaging for a tight engine bay

- You prefer firm, responsive brake feel

- You have a heavy vehicle (over 3,500 pounds)

- You regularly tow or carry heavy loads

- You use your vehicle in performance or off-road applications

Compatibility with Different Engine Types

Your engine configuration greatly influences which system will work best.

Naturally Aspirated Engines

Most naturally aspirated engines produce sufficient vacuum for brake boosters. The typical intake manifold vacuum (16-21 inches Hg at idle) provides ample assist for everyday driving situations. This makes vacuum boosters the logical, cost-effective choice for most stock applications.

Modified and Forced Induction Engines

High-performance cams, turbochargers, and superchargers all reduce available vacuum. Racing cams with long duration and overlap can drop vacuum below 12 inches Hg – insufficient for proper vacuum booster operation.

For these applications, hydroboost systems shine. Since they don’t rely on engine vacuum, they maintain full braking assistance regardless of engine modifications or throttle position.

Real-World Performance Under Stress

When the pressure’s on, how do these systems compare?

Emergency Braking Scenarios

In panic stops, hydroboost systems typically provide more immediate response with less pedal travel. This can translate to slightly shorter stopping distances and more confident braking in emergencies.

Vacuum systems may require more pedal pressure during repeated hard stops as vacuum reserves deplete. This “brake fade” effect is most noticeable in aggressive driving or downhill descents.

Extreme Conditions

Both systems have different vulnerabilities in extreme conditions:

- Vacuum boosters struggle at high altitudes (less atmospheric pressure)

- Hydroboost systems can be affected by very cold temperatures until fluid warms up

- Vacuum systems perform inconsistently during spirited driving with frequent acceleration

- Hydroboost maintains performance regardless of how hard you’re pushing the engine

Making the Switch: Upgrade Considerations

If you’re contemplating switching from vacuum to hydroboost, here’s what you should know.

Conversion Requirements

Converting to hydroboost typically requires:

- The hydroboost unit itself

- Compatible master cylinder (often included in kits)

- Power steering pump with sufficient pressure capacity

- High-pressure hoses and proper routing

- Pedal linkage modifications

Many manufacturers offer complete conversion kits that include all necessary components, making the process more straightforward.

Expected Results

After conversion, most drivers notice:

- Firmer pedal feel with less travel

- More consistent braking performance

- Improved engine performance (by eliminating vacuum draw)

- Better packaging and underhood appearance

- Increased confidence in braking, especially in modified vehicles

The Future of Brake Boosting Technology

While vacuum and hydroboost systems dominate today’s market, emerging technologies are on the horizon.

Electric Brake Boosters

Electric brake boosters are gaining popularity, especially in hybrid and electric vehicles. These systems use an electric motor rather than vacuum or hydraulic pressure to provide brake assistance. Benefits include:

- No reliance on engine vacuum or hydraulic systems

- Programmable assistance for different driving modes

- Better integration with electronic stability and autonomous driving systems

- Improved packaging flexibility

As vehicles continue to electrify, we’ll likely see these systems become more common across all vehicle types.

The Verdict: Making Your Final Decision

When choosing between hydroboost and vacuum boost, consider these factors:

- Vehicle weight and braking demands

- Engine configuration and vacuum availability

- Available underhood space

- Budget constraints

- Desired pedal feel and braking characteristics

For most stock street vehicles, vacuum boosters remain the practical, cost-effective choice. For performance builds, heavy-duty applications, or modified engines, hydroboost systems offer superior and more consistent braking power despite their higher cost and complexity.

Whichever system you choose, proper installation and maintenance are crucial for safe, reliable braking performance. Your brakes are your vehicle’s most important safety system – invest accordingly.