Looking for reliable power without breaking the bank? The GM 602 crate engine might be just what you need. Whether you’re building a weekend racer or looking to compete in sanctioned events, understanding the specs and capabilities of this popular powerplant is essential. Let’s dive into everything that makes the 602 crate engine a favorite among budget-conscious racers and enthusiasts.

What is a 602 Crate Engine?

The GM 602 crate engine, officially known as the CT350, is General Motors’ entry-level solution for affordable circle track racing. Introduced in 2002, this factory-sealed 350-cubic-inch small-block Chevrolet engine delivers impressive performance at a fraction of the cost of custom-built race engines.

Unlike hand-built racing engines that can cost upwards of $15,000, the 602 comes ready to run from the factory at a much more wallet-friendly price point. It’s become the backbone of many entry-level racing series, creating a level playing field where driver skill matters more than engine-building budgets.

Core Performance Specifications

The 602 crate engine delivers impressive power and torque that make it ideal for circle track applications:

- Horsepower: 350 hp at 5,400 RPM

- Torque: 396 lb-ft at 3,800 RPM

- Displacement: 350 cubic inches (5.7 liters)

- Compression Ratio: 9.1:1

- Recommended Fuel: 92-93 octane unleaded gasoline

- Maximum RPM: 5,500

What makes these numbers particularly impressive is the broad torque curve, providing more than 300 lb-ft of torque from 2,000 to 5,500 RPM. This wide powerband gives drivers excellent drivability and allows them to hold gears longer in racing situations.

Engine Block and Bottom End Specs

The foundation of the 602 crate engine is built for reliability under racing conditions:

Block Construction

- Cast iron, four-bolt main bearing cap block

- Part numbers: 10243880 or 14093638

- Deck height: 9.025 inches (± 0.001 inch)

- One-piece rear seal design

Crankshaft and Connecting Rods

- Cast iron or nodular iron crankshaft

- Standard 3.480-inch stroke

- Powder metal connecting rods measuring 5.7 inches in length

- Rod weight: 604.15 grams (± 10.0 grams)

- Secured with 3/8-inch rod bolts

Pistons

- Hypereutectic cast aluminum pistons (part number 88894280)

- Dished design with four valve reliefs

- 3.996 inches in diameter

This combination of components creates a robust bottom end that can withstand the rigors of competitive racing while maintaining reasonable costs for teams on a budget.

Cylinder Head Technology

The 602 uses GM Vortec iron cylinder heads (part number 12558062) that provide excellent airflow characteristics:

Head Specifications

- 64cc combustion chambers

- 170cc intake ports

- 77cc exhaust ports

- 23-degree valve angle from deck surface

Valve Configuration

- 1.94-inch intake valves

- 1.50-inch exhaust valves

- Precision-machined valve seats

These Vortec heads offer a great balance of performance and durability, with port designs that promote excellent air velocity and combustion efficiency.

Camshaft and Valvetrain Details

The camshaft and valvetrain components are specifically designed to optimize the engine’s powerband for circle track racing:

Camshaft Specs

- Hydraulic flat tappet design (part number 24502476)

- 0.435-inch intake lift

- 0.460-inch exhaust lift

- 212 degrees intake duration (at 0.050-inch tappet lift)

- 222 degrees exhaust duration (at 0.050-inch tappet lift)

- 112.5-degree lobe separation angle

Valvetrain Components

- Stamped steel rocker arms with 1.5:1 ratio

- “Kool Nut” design with set screw locking mechanism

- Valve springs (part number 10212811) with 1.250-inch diameter

- Spring free height of 2.021 inches

- 80 pounds (± 4 pounds) of pressure at installed height

- 195 pounds (± 8 pounds) of pressure at full lift

This valvetrain package delivers reliable performance within the engine’s intended RPM range while maintaining the cost-effectiveness that makes the 602 so appealing.

Induction and Fuel System

The induction system is tailored to maximize the engine’s torque characteristics:

Intake Manifold

- Dual-plane, high-rise aluminum design (part number 12366573)

- Eight-bolt mounting configuration

- Specifically designed for Vortec cylinder head bolt pattern

Carburetion

- Recommended carburetor: Holley 650 HP (part number 80541-1)

- Baseline jetting: size 73 jets front and rear

Interestingly, testing has shown that larger 750 CFM carburetors actually hurt performance in racing conditions. While they produce similar dyno numbers, they cause the engine to run too rich in corners, negatively impacting track performance. The specified 650 CFM carburetor provides optimal fuel metering for the engine’s intended use.

Lubrication and Cooling Systems

Proper lubrication is critical for racing engine longevity:

Oil System

- Wet sump oiling system

- 8-quart capacity oil pan (including filter)

- 8.5-inch deep pan with kick-out design

- Three trap doors for oil control during cornering

- Built-in crankshaft scraper and louvered windage tray

- Normal oil pressure: 40 PSI at 2,000 RPM

- Recommended oil: Mobil 1 15W-50 synthetic racing oil

Cooling Requirements

- Minimum two-core radiator mounted in front of the engine

- Copper, brass, or aluminum radiators permitted

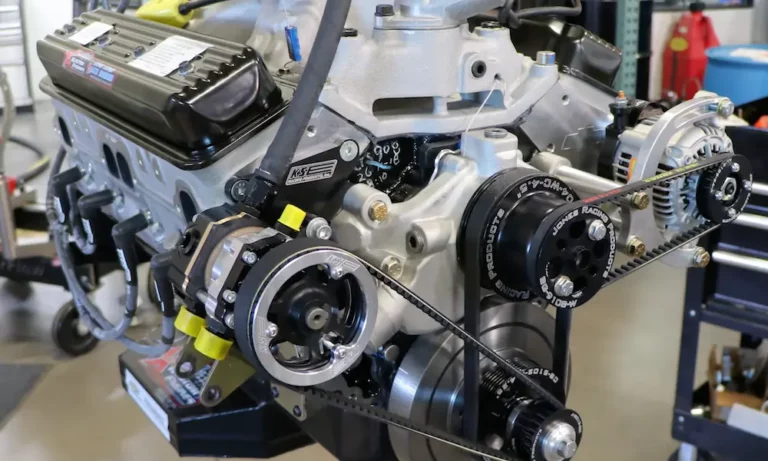

- V-belt pulleys (steel or aluminum)

The cooling and oiling systems are designed to maintain proper operating temperatures and lubrication under the demanding conditions of circle track racing.

Ignition and Electrical Systems

The ignition system provides reliable spark across the operating range:

Ignition Components

- HEI (High Energy Ignition) distributor

- 32-34 degrees total advance at 4,000 RPM

- Mechanical advance curve:

- 0 degrees at 1,100 RPM

- 12 degrees at 1,600 RPM

- 16 degrees at 2,400 RPM

- 22 degrees at 4,600 RPM

- Standard small-block Chevrolet firing order: 1-8-4-3-6-5-7-2

Spark Plugs

- AC Delco MR43LTS spark plugs

- 0.045-inch gap

The ignition timing and components are specifically calibrated for the 602’s compression ratio and fuel requirements, providing optimal performance and reliability.

Factory Sealing System

One of the most important aspects of the 602 crate engine is its factory sealing system, which ensures a level playing field in sanctioned racing:

Sealing Methods

- Eight specially designed bolts in critical locations:

- Two bolts in the intake manifold

- Two bolts in the front cover

- Two bolts in the oil pan

- One bolt in each cylinder head

- Each bolt features GM logo laser-etched on the head

- Info-Glyph dot-matrix encoding for authentication

- Bolts break off at specific torque values during installation

Sanctioning Body Requirements

- IMCA regulations require additional Cable-Lok seals

- Violation of sealing integrity results in severe penalties:

- Disqualification

- Loss of points

- $5,000 fine

- 30-day suspension

This comprehensive sealing system ensures that all competitors have mechanically identical engines, making driver skill and chassis setup the deciding factors.

Racing Applications

The 602 crate engine has become the standard in many entry-level racing classes:

Common Racing Classes

- IMCA Hobby Stock (most common application)

- IMCA Sport Modified (Northern regions and specific tracks)

- Factory Stock classes (various regional series)

- Modified divisions (budget-conscious competitors)

- Truck classes (some sanctioning bodies)

Regional Series

- Mid-East 602 Late Models

- Fastrak Racing Series

- Indiana Late Model Series (IMLS)

- Crate Racin’ USA (CRUSA)

- RUSH Racing Series

This widespread adoption across multiple racing series has created a robust ecosystem of support and parts availability.

Price and Value Proposition

The 602 crate engine represents excellent value for competitive racers:

Current Market Pricing

- Base engine: $7,293 – $7,950

- Dyno-tested versions: $7,850 – $8,300

- Fully dressed packages: $8,200 – $8,500

- Race-ready builds: $8,700 – $11,000

Value Benefits

- Cost control – Eliminates expensive engine building programs

- Competitive parity – All competitors use identical engines

- Reduced maintenance – Engines typically last entire seasons

- Simplified tech inspection – Sealed format prevents modifications

- Increased participation – Lower costs attract more competitors

When compared to custom-built race engines that can cost $15,000 or more, the 602 offers remarkable performance per dollar.

Maintenance Requirements

Proper maintenance is essential for getting the most life and performance from a 602 crate engine:

Break-In Procedures

- Initial 30-minute run at 2,000-2,500 RPM with no load

- Valve lash adjustment to proper specifications

- Timing and carburetor adjustment to recommended settings

- First 30 laps at varying speeds with moderate throttle

- Gradual RPM increase with specific acceleration cycles

- Oil and filter changes after break-in periods

Routine Maintenance

- Regular oil changes using recommended synthetic racing oil

- Valve spring replacement when pressures decline

- Valve lash adjustment as needed

- Spark plug replacement and gap verification

- General inspection of sealing bolts and components

With proper maintenance and operation within recommended parameters, most sealed 602 engines provide 2-3 seasons of competitive service before requiring rebuilding or replacement.

602 vs. 604 Crate Engine Comparison

The GM 604 crate engine serves as the next performance level above the 602. Understanding the differences helps racers choose the right engine for their application:

| Specification | 602 Crate Engine | 604 Crate Engine |

|---|---|---|

| Horsepower | 350 HP at 5,400 RPM | 404 HP at 5,600 RPM |

| Torque | 396 lb-ft at 3,800 RPM | 406 lb-ft at 4,600 RPM |

| Cylinder Heads | Iron Vortec heads | Aluminum Fast-Burn heads |

| Camshaft Type | Flat tappet | Roller |

| Compression Ratio | 9.1:1 | 9.7:1 |

| Price Range | $7,300-$8,300 | $8,900-$10,000 |

While the 604 offers superior peak power, the 602 provides better low-end torque characteristics and significantly lower acquisition costs, making it the preferred choice for entry-level racing.

Where to Buy and Availability

If you’re in the market for a 602 crate engine, here’s what you need to know:

Purchase Options

- Karl Kustoms offers both base and dyno-tested versions

- SD Parts provides multiple configuration options

- Local Chevrolet Performance dealers

- Specialized racing parts distributors

Lead Times and Availability

- Current lead times typically range from 2-8 weeks

- Some dealers maintain limited stock for immediate delivery

- Spring months experience highest demand as racing seasons begin

- Financing options and trade-in programs are available from many dealers

When purchasing, consider whether you need a base engine or a fully dressed version ready to bolt in and race.

Building a Competitive Race Car with the 602

To maximize the potential of your 602 crate engine in competition:

Chassis Optimization

- Focus on suspension setup and handling

- Invest in quality shocks and springs

- Ensure proper weight distribution

- Maintain correct chassis alignment

Transmission and Gearing

- Choose gear ratios that keep the engine in its optimal powerband

- Consider track size and banking when selecting final drive ratio

- Quality transmission coolers help maintain consistent performance

Exhaust System Selection

- Header primary tube diameter: 1.5-1.625 inches

- Collector size: 3-3.5 inches

- Muffler selection based on track sound requirements

With identical engines across the field, these supporting components and setups become the differentiators that separate winners from the pack.

Real-World Performance and Durability

Racers report consistent performance from the 602 crate engine:

- Typical lap times comparable to much more expensive engines in similar classes

- Broad torque curve makes the engine forgiving and easy to drive

- 2-3 season lifespan with proper maintenance

- Excellent reliability when operated within specified RPM limits

The 602’s reputation for durability has made it a favorite among racers who prefer spending time competing rather than constantly rebuilding engines.

How the 602 Changed Racing

The introduction and widespread adoption of the 602 crate engine has had profound effects on grassroots racing:

- Reduced the financial barrier to entry for new competitors

- Created more competitive, closer racing with identical powerplants

- Shifted focus from engine building to driver skill and chassis setup

- Increased car counts at many tracks and series

- Provided a sustainable model for affordable racing

This transformation has revitalized many racing series that were struggling with declining participation due to escalating engine costs.

The GM 602 crate engine represents an ideal balance of performance, reliability, and affordability for circle track racing applications. Its 350 horsepower and 396 lb-ft of torque, combined with robust construction and factory sealing, provide consistent, competitive performance while controlling costs for budget-conscious racers.

With proper maintenance and operation within recommended parameters, the 602 offers excellent return on investment for racers seeking to compete rather than constantly wrench on their engines. The factory sealing system ensures parity while the comprehensive support network of dealers and rebuild facilities provides long-term viability for this popular racing engine platform.