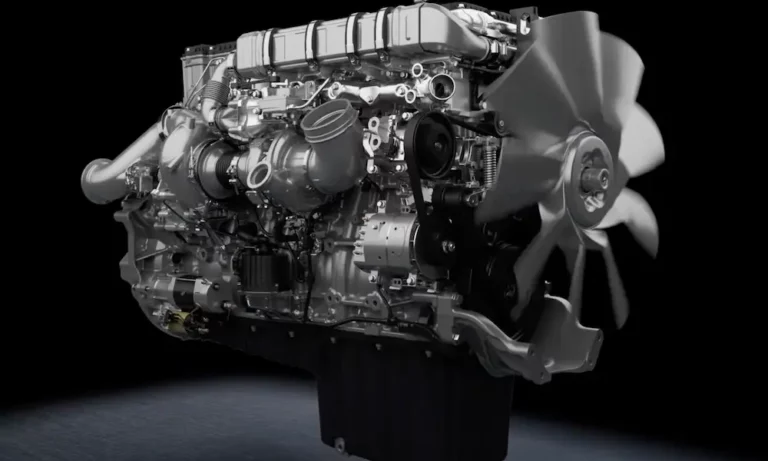

Looking for a heavy-duty diesel engine that can handle extreme conditions? The Detroit DD16 engine might be just what you need. With its massive 15.6-liter displacement and ability to deliver up to 600 horsepower, this powerhouse is built for the toughest jobs out there. If you’re considering this engine for your next truck or want to understand what makes it special, you’ve come to the right place.

Core DD16 Engine Specifications at a Glance

The DD16 stands as Detroit’s largest and most powerful on-highway diesel engine ever produced. Here’s what makes it tick:

| Specification | Details |

|---|---|

| Configuration | Inline 6-cylinder |

| Displacement | 15.6 liters (952 cubic inches) |

| Bore × Stroke | 5.47″ × 6.73″ (139mm × 171mm) |

| Compression Ratio | 17:1 |

| Horsepower Range | 500-600 HP @ 1,800 RPM |

| Torque Range | 1,850-2,050 lb-ft @ 975 RPM |

| Weight | 2,837 pounds (1,287 kg) |

| Oil Capacity | 45 quarts (43 liters) with filter |

The engine’s physical design reflects its heavy-duty nature. The ribbed cast iron block isn’t just about strength—it’s also engineered to reduce noise and vibration, making for a more comfortable driving experience. That low-end torque peak at just 975 RPM is particularly noteworthy, as it delivers maximum pulling power exactly where trucks need it most.

Power and Performance Capabilities

What really sets the DD16 apart is its impressive performance profile. The engine delivers:

Exceptional Low-End Torque

The DD16’s wide, flat torque curve maintains strong output down to 1,000 RPM and below. This isn’t just a technical achievement—it translates to real-world benefits like maintaining highway speeds on steep grades without downshifting. You’ll experience less transmission wear and better fuel economy since the engine can “hang in top gear longer” during challenging conditions.

Power Ratings for Every Need

With options ranging from 500 to 600 horsepower, the DD16 can be configured to match specific application requirements. Whether you’re in construction, mining, logging, or long-haul trucking, there’s a power rating to match your needs.

Real-World Fuel Economy

Actual fuel economy varies significantly based on application:

- Long-haul applications typically achieve 5.0-6.5 MPG

- Some operators report up to 6.3 MPG under optimal conditions

- Heavy-haul applications pulling 140,000-pound loads typically see 4.5-5.0 MPG

Compared to competitors like the Cummins X15, operators report that the DD16 often achieves about 0.8 MPG better fuel economy when pulling the heaviest loads.

Advanced Fuel and Air Management Systems

The DD16’s impressive performance comes from cutting-edge technology under the hood:

Second-Generation ACRS Fuel System

The DD16 uses Detroit’s proprietary Amplified Common Rail System (ACRS), one of the most advanced fuel injection technologies available. The system operates at injection pressures up to 38,000 PSI within the injector, allowing for:

- Precise fuel delivery for quieter, smoother combustion

- Variable injection patterns optimized for fuel economy

- Final high-pressure amplification isolated within the injector rather than in the rail or fuel lines

This sophisticated approach reduces stress on components while maximizing efficiency and minimizing emissions.

Turbocharging and Energy Recovery

The advanced turbocharging system delivers exceptional response across the engine’s operating range. Some configurations offer turbo-compounding technology that recovers thermal energy from the exhaust stream—turning normally wasted energy into usable power without sacrificing fuel economy.

The cooling system works with the turbocharger to decrease fan-on time, contributing to reduced fuel consumption and improved overall efficiency.

Electronic Control and Diagnostics

Modern diesel engines are as much about software as hardware, and the DD16 excels in this area too:

DDEC Electronic Control System

Every DD16 comes equipped with Detroit Diesel Electronic Control (DDEC) systems. These sophisticated controllers process over 100 different sensor inputs thousands of times per second, constantly adjusting:

- Injection timing

- Fuel quantity

- Turbocharger boost pressure

- Exhaust gas recirculation rates

The result is an engine that’s always operating at peak efficiency regardless of conditions.

Detroit Connect Virtual Technician

This remote diagnostic system is a game-changer for fleet management. When fault events occur, Virtual Technician can notify fleet managers within minutes, including:

- Fault severity assessment

- Recommended repair actions

- When to continue operation or stop immediately

This preventive approach reduces downtime and helps avoid catastrophic failures.

Emissions Compliance Without Performance Compromise

The DD16 meets stringent emissions requirements while maintaining its performance edge:

Comprehensive Compliance

Depending on model year and configuration, the DD16 meets:

- EPA 2010 standards

- GHG14 (Greenhouse Gas 2014) requirements

- GHG17 requirements

- Available GHG21 compliance

Integrated SCR Technology

Detroit’s integrated Selective Catalytic Reduction (SCR) emissions system uses their exclusive “1-Box Configuration” to meet tailpipe standards without sacrificing performance or fuel efficiency. This EPA-compliant system ensures the DD16 can operate legally in all U.S. markets.

Maintenance and Service Intervals

Nobody wants excessive downtime, and the DD16 is designed with serviceability in mind:

Extended Oil Change Intervals

The DD16 offers respectable maintenance intervals that vary by application:

- 35,000 miles for severe-duty applications

- 55,000 miles for long-haul applications

While some ultra-efficient engines can stretch to 75,000 miles between oil changes, the DD16’s power-focused design typically doesn’t qualify for these extended intervals.

Operator-Friendly Design Features

Detroit engineered the DD16 with maintenance accessibility as a priority:

- All routine service items including cartridge-style oil and fuel filters are positioned above the frame rails

- Above-frame positioning enables faster, cleaner filter changes

- Modular construction simplifies parts replacement

- Support network includes over 800 authorized service outlets

Primary Applications and Industries

The DD16 isn’t for everyone—it’s specifically designed for the most demanding applications:

Heavy-Duty Vocations

You’ll find the DD16 powering equipment in:

- Construction

- Mining operations

- Logging applications

- Heavy-haul trucking (especially loads over 80,000 pounds)

- Oil field services

- Specialized transportation

Available Vehicle Platforms

The engine is offered in several premium heavy-duty trucks:

- Freightliner Cascadia

- Western Star 4900 series

- Western Star 6900 series

- Other specialized commercial vehicles

Reliability and Longevity Expectations

Heavy-duty engines need to last, and the DD16 is built for the long haul:

B50 Service Life Rating

Detroit rates the DD16 with a B50 life of 1.2 million miles. This means 50% of engines should reach this mileage before requiring major overhaul—a testament to the engine’s robust construction and heavy-duty design philosophy.

Common Maintenance Issues

No engine is perfect, and field reports indicate several typical maintenance items for DD16 engines:

- Injector cup replacement (around 2 years of service when diesel fuel appears in coolant)

- Oil leaks around the oil pan and filter housing

- Water pump replacement (approximately 4 years)

- One-box emissions system issues after 4 years of operation

Most owners report these as expected maintenance items rather than design flaws.

How the DD16 Compares to Competitors

The heavy-duty diesel market has several strong contenders. Here’s how the DD16 stacks up:

Competitive Landscape

The DD16 directly competes with:

- Cummins X15

- Caterpillar C15/C16 engines

In performance comparisons, the DD16 typically shows:

- Stronger low-end torque characteristics

- Excellent gradeability

- Superior hill-climbing ability compared to some competitors

Integrated Engine Braking

The DD16’s integrated Jacobs engine brake provides three levels of braking performance, offering enhanced downhill control and reduced wear on service brakes. This feature is particularly valuable for heavy loads on mountain routes.

Recent Technology Developments

Detroit continues to refine the DD16 with ongoing improvements:

2025 Model Year Enhancements

Recent updates have brought:

- Enhanced thermal efficiency

- Updated EGR systems

- New turbo architecture

- Up to 4% better fuel efficiency compared to previous models

Telematics Integration

Advanced telematics through Detroit Connect now provide:

- Real-time performance monitoring

- Remote diagnostics

- Over-the-air software updates

- Predictive maintenance capabilities

Choosing the Right DD16 Configuration

When specifying a DD16 engine, consider these factors:

Power Rating Selection

Select your horsepower and torque rating based on:

- Typical payload weight

- Terrain in your operating area

- Desired cruise speed

- Fuel economy goals

The highest 600 HP rating isn’t always necessary—sometimes the 500 or 550 HP options provide better overall efficiency for your specific application.

Transmission Pairing

The DD16 works best with:

- Detroit DT12 automated manual transmission

- Allison automatics for vocational applications

- Eaton manual transmissions for operator preference

The right transmission pairing can maximize the DD16’s torque characteristics and improve overall efficiency.

DD16 in Extreme Conditions

The DD16 really shines when the going gets tough:

High-Temperature Performance

With its advanced cooling system, the DD16 maintains performance in desert conditions and high-temperature environments. The engine’s thermal management systems help prevent power deration even under extreme heat.

Cold Weather Operation

In frigid conditions, the DD16’s robust starting system and block heater options ensure reliable cold starts. The electronic controls automatically adjust parameters for optimal cold-weather operation.

High-Altitude Capability

Thanks to its turbocharging system, the DD16 maintains impressive power at high elevations where naturally aspirated engines struggle. The electronic controls automatically compensate for changes in air density, helping maintain performance in mountain operations.

Future Outlook for the DD16

Detroit continues to evolve this flagship engine:

Emissions Compliance Path

With upcoming EPA regulations targeting further emissions reductions, Detroit is developing solutions to meet these standards while maintaining the DD16’s performance profile.

Efficiency Improvements

Detroit’s engineering team continues to focus on incremental efficiency gains through:

- Advanced combustion design

- Reduced internal friction

- Improved thermal management

- Enhanced electronic controls

These ongoing improvements help ensure the DD16 remains competitive in a rapidly evolving market.

Is the DD16 Right for Your Application?

The DD16 represents the pinnacle of Detroit’s heavy-duty diesel technology, but it’s not the ideal choice for everyone. Consider these factors when deciding if it’s right for you:

When the DD16 Makes Sense

The DD16 is the perfect choice when:

- You regularly pull loads over 80,000 pounds

- Your routes include significant mountain grades

- Maximum pulling power is more important than absolute fuel economy

- You need durability for extreme-duty cycles

- You want the confidence of maximum power reserves

When to Consider Alternatives

You might want to look at the DD15 or competitors if:

- Your typical loads are under 80,000 pounds

- You operate primarily in flat terrain

- Maximum fuel economy is your top priority

- Initial purchase cost is a major concern

- Your application doesn’t require extreme power

Remember that while the DD16 offers unmatched power, the DD15 can be more fuel-efficient in less demanding applications.

The Complete Detroit DD16 Engine Specifications

For those who need all the technical details, here’s the complete specification list:

| Specification | Details |

|---|---|

| Engine Type | 4-stroke diesel, inline 6-cylinder |

| Displacement | 15.6L (952 cu in) |

| Bore × Stroke | 5.47″ × 6.73″ (139mm × 171mm) |

| Compression Ratio | 17:1 |

| Weight (Dry) | 2,837 lbs (1,287 kg) |

| Horsepower Range | 500-600 HP @ 1,800 RPM |

| Peak Torque Range | 1,850-2,050 lb-ft @ 975 RPM |

| Governed Speed | 2,080 RPM |

| Oil Capacity | 45 quarts (43 liters) with filter |

| Coolant Capacity | Varies by installation |

| Fuel System | ACRS (Amplified Common Rail System) |

| Injection Pressure | Up to 38,000 PSI |

| Emissions Technology | SCR with DOC and DPF |

| Electronics | DDEC (Detroit Diesel Electronic Control) |

| Engine Brake | Integrated Jacobs Engine Brake |

| B50 Life | 1.2 million miles |

| Warranty | Base 2-year/unlimited miles |

The Detroit DD16 represents the culmination of heavy-duty diesel engineering, offering exceptional power, torque, and reliability for the most demanding commercial applications. With its massive displacement, advanced fuel injection technology, and comprehensive electronic controls, it delivers the performance characteristics required for extreme-duty trucking while meeting stringent emissions standards.

Its wide torque curve, extended service intervals, and robust construction make it particularly well-suited for applications requiring maximum pulling power and long-term durability. While maintenance costs may be higher than smaller displacement engines, the DD16’s capability to handle the heaviest loads and most challenging operating conditions positions it as the preferred choice for operators who prioritize power and performance.