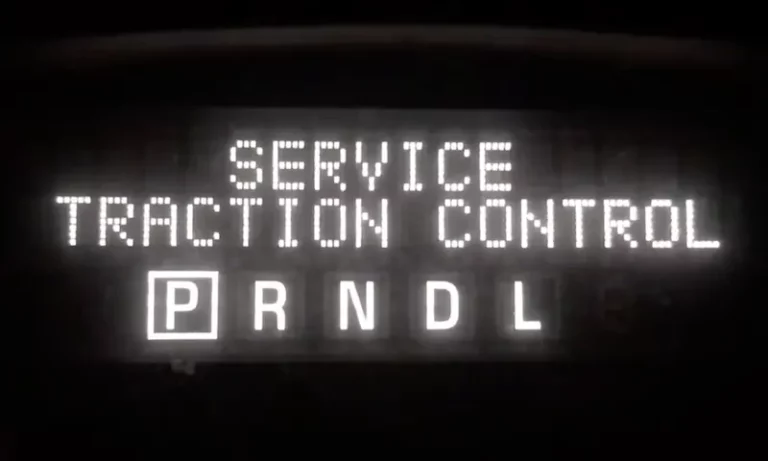

When that “Service Traction Control System” light pops up on your dashboard, it’s not just an annoying reminder—it’s your car telling you something important. This critical safety system helps keep your wheels from spinning during acceleration and works alongside your anti-lock brakes to maintain stability, especially on slippery roads. Understanding what’s happening when this warning appears can save you money, keep you safer, and prevent bigger problems down the road.

The traction control system is constantly monitoring your wheels through sensors and making split-second decisions to keep you in control. When something goes wrong with any part of this complex network, your car lets you know with that dashboard warning. Let’s break down what this system does, what commonly fails, and how to get it working properly again.

Understanding Traction Control System Components

Core System Architecture

Your traction control system relies on several key components working together perfectly. Wheel speed sensors are mounted at each wheel to detect when one wheel spins faster than the others—the most common sign of lost traction. These sensors continuously send data to the Electronic Control Unit (ECU), which processes this information and decides when to intervene.

The system also includes hydraulic components like the ABS pump and solenoid valves that can apply braking force to specific wheels. When one wheel starts spinning faster than the others, these components can slow it down, allowing power to transfer to wheels with better traction. Supporting this network are pressure accumulators for hydraulic pressure storage and reluctor rings (also called tone rings) that provide magnetic signatures for the wheel sensors to read.

All these components connect through wiring harnesses that are exposed to road salt, water, and debris—making them vulnerable to damage and corrosion over time.

Integration with Vehicle Safety Systems

Modern traction control doesn’t work alone. It’s deeply integrated with your anti-lock braking system (ABS) and electronic stability control. This integration explains why you might see multiple warning lights (like ABS and traction control) illuminate at the same time—a problem with one system often affects the others.

Your car also uses yaw rate sensors and steering angle sensors to understand how the vehicle is moving compared to how you’re steering. This additional input helps the traction control system make better decisions about when and how to intervene during challenging driving conditions.

Common Problems and Their Causes

Wheel Speed Sensor Issues

Wheel speed sensor problems account for about 40% of all traction control system failures. These sensors are constantly exposed to harsh conditions including:

- Dirt and mud accumulation

- Road salt corrosion

- Water and moisture damage

- Impact from stones and road debris

- Extreme temperature changes

Sensor contamination happens when brake dust, metal particles, or road grime interferes with the sensor’s ability to read the reluctor ring properly. In many cases, simply cleaning the sensor can restore normal function. However, sensors can also suffer physical damage from impacts or internal electrical failures that require complete replacement.

Electrical and Wiring Problems

About 25% of traction control failures stem from electrical issues, which can be the trickiest to diagnose. Corroded connections are extremely common, especially in vehicles regularly exposed to road salt or high humidity. The wiring harnesses connecting sensors to control modules run along the undercarriage where they’re vulnerable to damage.

Loose connections create intermittent problems that might come and go depending on driving conditions. You might notice the warning light appears only when turning or hitting bumps. Short circuits and broken wires can completely disable the system or cause unpredictable behavior.

ABS and Hydraulic System Problems

Since traction control shares components with your ABS system, ABS-related issues account for approximately 15% of traction control failures. Common problems include:

- Low brake fluid levels preventing proper hydraulic pressure

- ABS pump failures eliminating the ability to apply individual wheel brakes

- Hydraulic valve problems causing inappropriate brake application

- Control module failures from electrical component breakdown

These hydraulic system issues typically require professional diagnosis with specialized equipment to pinpoint the exact failing component.

| Component | Failure Rate | Average Repair Cost |

|---|---|---|

| Wheel Speed Sensors | 40% | $150-900 |

| Electrical/Wiring | 25% | $200-600 |

| ABS/Hydraulic System | 15% | $800-1500 |

| Control Modules | 10% | $500-1500 |

| Other Components | 10% | Varies |

Diagnostic Procedures and Troubleshooting

Initial Assessment and Code Reading

Professional diagnosis starts with connecting an OBD-II scanner to retrieve diagnostic trouble codes (DTCs) from your vehicle’s computer. These codes provide valuable clues about which component is causing the problem. Common codes include:

- C0031-C0034: Wheel speed sensor circuit problems

- C0110: ABS pump motor issues

- C0121: Valve relay circuit malfunctions

Technicians follow a systematic testing approach for each component identified by the trouble codes. This includes measuring sensor resistance, checking signal voltage, and testing continuity throughout the electrical circuits. A visual inspection often reveals obvious problems like damaged wiring, corroded connections, or contaminated sensors.

Component Testing Procedures

Wheel speed sensor testing involves checking both electrical properties and mechanical installation. The proper air gap between sensor and reluctor ring is critical for accurate readings. Resistance measurements help identify internal sensor failures, while oscilloscope testing can reveal signal quality issues.

Hydraulic system testing requires checking brake fluid levels, pump operation, and valve functionality. Technicians may perform pressure tests to verify the system can build and maintain adequate hydraulic pressure. Control module testing involves verifying power supply, ground connections, and communication with other vehicle systems.

Repair Solutions and Cost Considerations

Basic Maintenance and Simple Repairs

Sensor cleaning is the most cost-effective solution when contamination is the primary issue. This typically costs between $50-100 and often resolves the problem completely. The process involves:

- Removing the wheel to access the sensor

- Carefully cleaning both the sensor tip and reluctor ring

- Checking connections for corrosion

- Reassembling and testing system operation

Wiring repairs may be necessary when connections are corroded or damaged. Simple connector cleaning and reseating sometimes fixes intermittent electrical problems. More extensive wiring harness repairs typically cost $200-600 depending on damage extent and accessibility.

Component Replacement

Wheel speed sensor replacement costs vary significantly based on your vehicle make and sensor location. Expect to pay between $150-900 per sensor including parts and labor. Labor costs typically account for $100-300 of the total, with the remainder being parts costs. Some vehicles require extensive disassembly to access certain sensors, increasing labor time and cost.

Control module replacement represents a more significant investment, with costs ranging from $500-1500. Professional module repair services can sometimes restore functionality for $300-600, offering a cost-effective alternative to complete replacement. These services typically address common internal failures like solder joint problems or component degradation.

Major System Repairs

Complete ABS module replacement may be necessary when multiple internal components fail, with costs typically ranging from $800-1500. This includes both the hydraulic pump and electronic control unit housed within the same assembly. Programming of new modules is often required to integrate them properly with the vehicle’s other systems.

System overhauls involving multiple components can cost $1500-3000 but are sometimes necessary in high-mileage vehicles where multiple components have reached end-of-life. These comprehensive repairs often include sensors, wiring harnesses, and control modules.

Preventive Maintenance and System Care

Regular Inspection Practices

You can significantly reduce the likelihood of major traction control failures through proactive maintenance:

- Visually inspect wheel speed sensors during tire rotations or brake service

- Maintain proper tire inflation and adequate tread depth

- Replace brake fluid according to manufacturer recommendations (typically every 2-3 years)

- Check for available software updates that might address known system issues

Environmental Considerations

Harsh driving conditions accelerate component deterioration. Vehicles operated in areas with road salt, mud, or standing water benefit from more frequent inspections and cleaning. After winter driving, thoroughly clean your vehicle’s undercarriage to remove salt and debris that can corrode electrical connections.

Your driving habits also impact system longevity. Aggressive acceleration on slippery surfaces places additional stress on components. Using appropriate tires for seasonal conditions reduces system workload and extends component life.

| Preventive Measure | Recommended Frequency | Benefit |

|---|---|---|

| Wheel sensor inspection | During tire rotation (5,000-7,000 miles) | Early detection of contamination |

| Brake fluid service | Every 2-3 years | Maintains hydraulic system performance |

| Undercarriage cleaning | After winter driving season | Prevents corrosion of electrical components |

| Tire maintenance | Monthly pressure checks | Reduces system activation frequency |

| Control module updates | As recommended by manufacturer | Addresses known software issues |

Safety Implications and Driving Considerations

Understanding System Limitations

A disabled traction control system significantly increases accident risk, particularly in slippery conditions. Without functional traction control, you must rely on traditional techniques to manage wheel spin and maintain control. Winter driving becomes especially hazardous, as wheel spin can lead to loss of directional control.

Risks of hydroplaning and skidding increase substantially when traction control is disabled. Studies from the National Highway Traffic Safety Administration indicate that vehicles with functioning traction control have significantly lower accident rates in adverse weather conditions compared to those with disabled systems.

When to Limit Driving

When your traction control warning light remains illuminated, seek professional attention immediately. While the vehicle may still be drivable, your safety margins are reduced, requiring extra caution and potentially avoiding certain driving conditions. Highway driving in rain or snow should be avoided until repairs are completed.

Emergency situations where traction control functionality is critical include navigating icy parking lots, merging onto wet highways, and driving on gravel or unpaved surfaces. In these situations, the lack of electronic assistance significantly increases the skill level required for safe vehicle control.

How Traction Control Systems Have Evolved

Today’s traction control systems have come a long way from their early iterations. Modern systems use sophisticated algorithms that can predict wheel slip before it happens by analyzing multiple sensors including wheel speed, steering angle, throttle position, and even outside temperature.

Many newer vehicles now feature selectable traction control modes tailored for specific conditions like snow, mud, or sport driving. These adaptive systems can modify their intervention thresholds based on driving conditions, providing just the right amount of control without feeling intrusive.

Some high-performance vehicles even incorporate launch control—a specialized traction control mode designed to provide maximum acceleration from a standstill while preventing wheel spin. This technology has migrated from racing applications to production vehicles, demonstrating how traction control continues to evolve.

Recognizing Early Warning Signs

Don’t wait for the “Service Traction Control System” light to address potential issues. Watch for these early warning signs:

- Momentary traction control light flashing during normal driving on dry pavement

- ABS light illuminating intermittently

- Unusual noises (grinding, clicking, or humming) from wheel areas

- Brake pedal pulsation when applying brakes normally

- Vehicle pulling to one side during gentle acceleration

- Inconsistent acceleration response on dry pavement

Addressing these symptoms early can prevent more extensive damage and keep repair costs lower. Many of these warning signs indicate sensor contamination or minor electrical issues that are relatively simple to fix before they progress to major system failures.

The “Service Traction Control System” warning demands prompt attention to maintain vehicle safety and performance. While wheel speed sensor contamination represents the most common and easily remedied cause, electrical problems and component failures require professional diagnosis and repair. By understanding the system’s components, common failure modes, and repair options, you can make informed decisions about maintaining this critical safety feature in your vehicle.