Looking for reliable information about the Caterpillar C7 diesel engine? Whether you’re considering buying a used truck with this powerplant or troubleshooting an existing engine, understanding its specifications is crucial. This guide breaks down everything from horsepower ratings to maintenance requirements, helping you make informed decisions about this medium-duty workhorse.

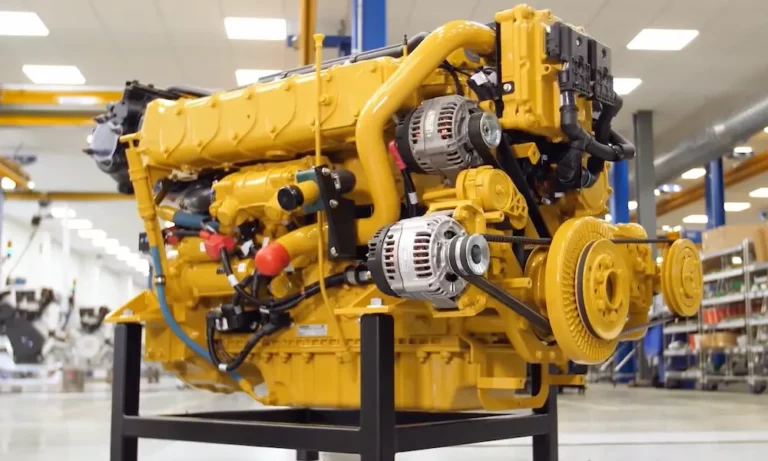

What Is the Caterpillar C7 Engine?

The Caterpillar C7 is a 7.2-liter inline-six diesel engine that served as Cat’s primary medium-duty offering from 2003 to 2009. Developed as a successor to the popular 3126 engine, the C7 was designed to meet the EPA’s stricter emission standards that took effect in 2004.

The engine found its home primarily in Class 8 medium-duty trucks with gross vehicle weight ratings between 18,000 and 33,000 pounds. Major manufacturers including Paccar, Freightliner, Ford, and GMC integrated the C7 into their vehicle lineups for applications ranging from box trucks to day cabs.

Core Caterpillar C7 Engine Specifications

Basic Configuration and Dimensions

The C7 features a straightforward inline-six design with a displacement of 7.2 liters (442 cubic inches). Here are the key measurements:

| Specification | Measurement |

|---|---|

| Bore | 4.33 inches (110 mm) |

| Stroke | 5.0 inches (127 mm) |

| Compression Ratio | 16.2:1 |

| Length | 41.5 inches (1053 mm) |

| Width | 29.8 inches (758 mm) |

| Height | 40.6 inches (1032 mm) |

| Dry Weight | 1,296 pounds (588 kg) |

The engine uses an undersquare design with a bore-to-stroke ratio of 0.866, which contributes to its torque characteristics and durability. It rotates counterclockwise when viewed from the flywheel end and follows a 1-5-3-6-2-4 firing order for balanced operation.

Power and Torque Ratings

One of the C7’s strengths was its versatility across different applications, with multiple power ratings available:

| Application | Horsepower Range | Torque Range |

|---|---|---|

| Truck/Bus | 210-300 hp (157-224 kW) | 520-860 lb-ft (705-1166 Nm) |

| RV/Fire Equipment | 330-360 hp (246-268 kW) | Up to 925 lb-ft (1254 Nm) |

Peak torque typically occurs between 1440-1600 rpm, while the rated operating speed range spans 1800-2200 rpm. The lower power models (210, 230, and 250 hp) were available with both low and high torque options to accommodate different transmission requirements preferred by various truck manufacturers.

The ACERT Technology Behind the C7

How ACERT Works

The C7 was one of the first engines to feature Caterpillar’s Advanced Combustion Emission Reduction Technology (ACERT), a sophisticated approach to controlling emissions. The system includes:

- Variable geometry turbocharger technology controlled by the engine control module

- Closed crankcase breather system

- Diesel particulate filter with engineered regeneration technology

Different power ratings used different turbocharger configurations:

- Smaller models: Multiple traditional wastegated turbochargers

- Mid-range models: Single turbocharger

- Higher power variants: Dual turbochargers working together

Fuel System Innovation

The C7 initially employed the Hydraulic Electronic Unit Injection (HEUI) system, which eliminated many mechanical components found in traditional fuel systems. This provided enhanced control over injection timing and fuel-air mixture ratios.

In 2007, the fuel system was updated to accommodate Ultra Low Sulfur Diesel (ULSD) requirements, transitioning to a common-rail injection system with injection pressures reaching 25,000 to 27,500 psi.

Unique Design Elements of the C7

Valve Train and Cylinder Head

The C7 features a three-valve-per-cylinder configuration with two intake valves and one exhaust valve. This design optimizes airflow while maintaining reliability. The cylinder head incorporates precision-machined ports and valve seats specifically optimized for the C7’s fuel system and ACERT technology.

The valve train differs notably from the predecessor 3126 engine, with modified gear train components featuring fewer teeth and more robust construction. Both the oil pump and water pump were enlarged to accommodate increased lubrication and cooling requirements.

Connecting Rods and Pistons

The C7 uses powdered metal connecting rods with a fractured cap design, differing from the forged rods used in the earlier 3126 engine. Two piston configurations are employed:

- A taller aluminum piston with a 1.811-inch wrist pin for 230 hp and higher versions

- A shorter steel piston with a 1.52-inch diameter wrist pin for engines below 210 hp

The crankshaft features smaller counterweights compared to the 3126 to accommodate the lighter weight piston design.

Control Systems and Electronics

Advanced Electronic Management

The C7 incorporates the ADEM A4 Electronic Control Unit with a 120-pin connection that significantly increases information processing capabilities. This system provides:

- Electronic governing

- PTO speed control

- Programmable engine ratings

- Automatic altitude compensation

- Power compensation for fuel temperature variations

- Programmable low and high idle settings

- Electronic diagnostics with fault logging

- SAE J1939 CAN bus communication

Cold Weather and Altitude Capability

The engine is designed for cold start capability down to -20°C (-4°F) without additional heating aids. The robust design enables operation at altitudes up to 10,000 feet (3,048 meters) with automatic compensation provided by the electronic control system.

C7 Applications and Industry Usage

The C7’s versatility made it suitable for numerous applications across multiple sectors:

- Transportation: Medium-duty trucks, day cabs, box trucks

- Emergency: Fire trucks and emergency vehicles

- Recreation: RVs and motorhomes

- Construction: Loaders, trenchers, compactors

- Agriculture: Tractors, combines, harvesters

- Industrial: Compressors, pumps, power units

The availability of front PTO options made it particularly valuable for specialized applications like fire trucks and emergency vehicles.

Service Life and Reliability

Expected Lifespan

According to industry B-rating standards, the C7 achieved a B50 rating of 450,000 to 500,000 miles. This means that statistically, 50% of C7 engines would require major overhaul or repair at approximately 500,000 miles of operation.

While this represents acceptable performance for medium-duty applications, it falls short of the million-mile service life achieved by some competing engines in the market.

Maintenance Requirements

Regular maintenance includes:

- Oil changes at intervals determined by operating conditions and oil analysis

- Regular inspection of fuel system components

- Periodic checks of coolant quality and level

For marine applications, maintenance schedules are typically more frequent:

- Daily checks of coolant levels, engine oil, and fuel system water separators

- Coolant changes every 1,000 hours

- Raw water pump impeller replacement every 500-1,000 hours

- Freshwater pump inspection every 2,000-3,000 hours

Emissions Compliance and Environmental Impact

The C7’s ACERT technology incorporates exhaust after-treatment systems that reduce NOx and particulate matter through oxidation catalyst agents. The after-treatment function operates automatically without requiring additional cleaning or maintenance from operators.

The engine meets several international emissions standards:

- EPA Tier 3 equivalent

- China Stage II

- EU Stage IIIA

These regulations represented significant environmental progress in diesel engine emissions control during the C7’s production period.

Production Timeline and Market Exit

Caterpillar produced the C7 engine from 2003 through 2009, representing a relatively short production run compared to some engine families. The limited period reflected the rapidly evolving emissions requirements and Caterpillar’s strategic decision to exit the on-highway engine market.

The company ultimately determined that the cost of continuously upgrading engines to meet increasingly stringent emissions requirements wasn’t economically viable, leading to their withdrawal from the over-the-road engine market in 2010. This decision created an opportunity for competitors like Cummins and Paccar to capture market share in the medium and heavy-duty truck segments.

The C7.1: Evolution of the Platform

Following the discontinuation of the original C7, Caterpillar developed the C7.1 engine for industrial, marine, and off-highway applications. The C7.1 represents a complete redesign with:

- Different displacement (7.01L vs. 7.2L)

- Updated bore and stroke dimensions

- Modern common rail fuel injection system

- Four-valve-per-cylinder configuration

- Compliance with EPA Tier 4 Final/EU Stage V emission standards

- Higher maximum power ratings up to 500 hp in marine applications

- Extended speed ranges up to 2900 rpm

The newer C7.1 engine platform continues to serve industrial and marine applications with updated technology and enhanced performance capabilities.

Common Issues and Troubleshooting

Fuel System Problems

The HEUI fuel system on the C7 is sophisticated but can develop issues:

- Injector failures often manifest as rough running, misfires, or poor fuel economy

- Low oil pressure can affect injector performance since the system uses engine oil for hydraulic actuation

- Fuel contamination is particularly problematic for the precision components

Cooling System Concerns

The C7 cooling system requires proper maintenance:

- Coolant must be kept clean and at the correct concentration

- Heat exchangers and radiators need periodic cleaning to prevent overheating

- Water pump failures can occur, especially in marine applications with raw water exposure

Electronic Control Issues

The sophisticated electronics can develop problems:

- Sensor failures can cause erratic operation or fault codes

- Wiring harness issues may develop over time, particularly in high-vibration applications

- ECM software updates may be required to address specific operational problems

Fluid Capacities and Service Information

Understanding the fluid capacities is essential for proper maintenance:

| System | Capacity |

|---|---|

| Standard Oil Capacity | 4.75 gallons (18 L) |

| Deep Sump Oil Pan | 6.75 gallons (25.5 L) |

| Cooling System | 3.99 gallons (15.1 L) |

| Marine Cooling System | Up to 27.0 gallons |

| Marine Lubrication System | 13-16 liters (refill) |

For optimal performance, Caterpillar recommends using:

- API CJ-4 or CI-4 oil grades

- Extended life coolant with appropriate SCA additives

- High-quality diesel fuel meeting ASTM D975 standards

Is the Cat C7 Right for Your Application?

Strengths of the C7 Platform

- Robust block and component design

- Good power-to-weight ratio for medium-duty applications

- Available in multiple power configurations

- Reputable Caterpillar service network

- Common parts availability despite discontinued production

Limitations to Consider

- Shorter service life than some competing engines

- ACERT technology complexity adds potential failure points

- Limited production run means fewer remaining low-hour examples

- Later emissions equipment adds maintenance considerations

- Not designed for extreme high-horsepower applications

For many medium-duty applications, the C7 represents a solid choice when properly maintained. However, applications requiring extremely long service intervals or maximum uptime might benefit from considering alternatives or the newer C7.1 platform.

Final Assessment: The C7’s Legacy

The Caterpillar C7 engine represents an important transitional design in medium-duty diesel engine development. Its relatively brief production period showcased significant technological advances including ACERT emissions control, HEUI fuel injection, and sophisticated electronic management systems.

While operational challenges with the ACERT technology ultimately influenced Caterpillar’s exit from the on-highway market, the C7 established engineering principles that continue in the current C7.1 platform. For buyers of used equipment, the C7 offers a proven medium-duty solution when found in well-maintained condition with documented service history.