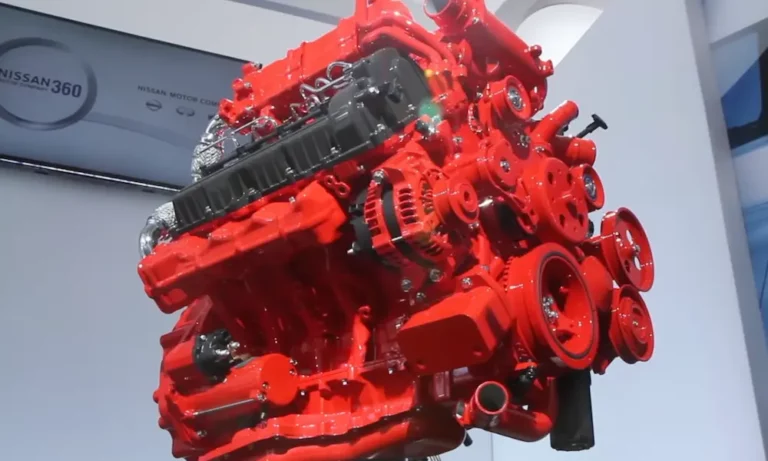

Thinking about a Cummins L10 engine for your commercial fleet or wondering what makes this powerplant tick? You’re in the right place. This straight-six diesel engine has powered everything from transit buses to excavators, earning a reputation for reliability and versatility that’s hard to match. Let’s dive into what makes the L10 special and why it might be the perfect fit for your heavy-duty applications.

The Evolution of the Cummins L10 Engine

The Cummins L-series kicked off in 1982 at the Jamestown Engine Plant in New York, with the L10 as its first offering. This 10.0-liter (611 cubic inches) inline-six diesel wasn’t just another engine – it was a game-changer for Cummins.

What made it revolutionary? Its adaptable design. You could mount it vertically for conventional trucks or horizontally for underfloor applications in buses and trains. This versatility opened doors in markets where previous Cummins engines were simply too large and heavy.

The L10 stayed in production until 1998, when it evolved into the M11 engine with a longer stroke and 10.8-liter displacement. Throughout its life, Cummins constantly refined the design to solve early issues like oil consumption and improve overall performance.

Core Physical Specs of the L10

Let’s talk numbers. The L10’s fundamental specs are what made it such a reliable workhorse:

| Specification | Measurement |

|---|---|

| Configuration | Inline 6-cylinder |

| Bore | 125mm (4.921 inches) |

| Stroke | 136mm (5.354 inches) |

| Displacement | 10.0 liters (611 cubic inches) |

| Firing Order | 1-5-3-6-2-4 |

| Rotation | Clockwise (viewed from front) |

| Dry Weight (Fixed Time) | 884.5kg (1950 lbs) |

| Dry Weight (CELECT) | 902.6kg (1990 lbs) |

| Wet Weight (Fixed Time) | 929.8kg (2050 lbs) |

| Wet Weight (CELECT) | 948.0kg (2090 lbs) |

The engine block and cylinder head were built from cast iron, giving the L10 excellent durability and thermal stability under load. Its overhead valve design with two valves per cylinder kept things simple, making maintenance easier and reducing potential failure points.

Power Ratings and Performance

Need power? The L10 delivered it in spades, with ratings tailored to different applications:

Urban Bus Applications

- 250 hp (186 kW) with 730 lb-ft (990 N⋅m) of torque at 1300 RPM

- 280 hp (209 kW) with 900 lb-ft (1,220 N⋅m)

- 330 hp (246 kW) with 1,100 lb-ft (1,491 N⋅m)

Commercial Trucks, Firetrucks, and Motorhomes

- Up to 400 hp (298 kW) with 1,200 lb-ft (1,627 N⋅m) of torque at 1300 RPM

These engines were typically governed at 2200 RPM for urban applications to ensure longevity in stop-and-go driving conditions.

The engine also found a home in construction equipment like the Liebherr 954 excavator, where the turbocharged intercooled variant produced 290 horsepower.

Operators could choose between different speed ratings:

- Industrial: 2100 RPM

- Standard: 1800 RPM

- Cruise: 1600 RPM

These options let you optimize for your specific duty cycle, balancing power needs against fuel efficiency.

Lubrication System: Keeping Things Running Smooth

A reliable lubrication system is crucial for any hard-working engine, and the L10’s was built to handle demanding conditions:

- Minimum oil pressure at low idle: 70 kPa (10 psi)

- Minimum oil pressure at 1200 RPM: 207 kPa (30 psi)

The oil capacity varied by application:

- Automotive: 26.5 to 34 liters (7-9 U.S. gallons)

- Industrial: 30.3 to 34 liters (8-9 U.S. gallons)

- Additional for filter system: 2.6 liters (0.7 U.S. gallons)

This substantial oil capacity was no accident – it helped maintain proper lubrication and cooling during high-load operations or extended duty cycles, extending engine life and reducing maintenance costs.

Cooling System: Maintaining Optimal Temperature

The L10’s cooling system was designed to keep the engine in its sweet spot across varying conditions:

- Coolant capacity: 9.5 liters (10 U.S. quarts) excluding radiator

- Standard thermostat range: 82°C to 93°C (180°F to 200°F)

- Minimum block pressure at 1800 RPM: 138 kPa (20 psi)

- Maximum allowable pressure: 275 kPa (40 psi)

- Maximum operating temperature: 100°C (212°F)

- Recommended minimum temperature: 70°C (158°F)

- Minimum pressure cap rating: 50 kPa (7 psi)

These specs ensured the engine ran at optimal temperatures, preventing overheating in hot conditions or during heavy loads while avoiding the inefficiency and increased wear of running too cool.

Air Induction and Exhaust Systems

Getting air in and exhaust out efficiently is critical for diesel performance. The L10’s specifications were:

Air Induction

- Maximum intake restriction (clean filter): 38 cm H₂O (15 in. H₂O)

- Maximum intake restriction (dirty filter): 64 cm H₂O (25 in. H₂O)

Exhaust System

- Maximum back pressure: 75 mm Hg (3 inches Hg) or 1016 mm H₂O (40 inches H₂O)

- Recommended exhaust pipe size: 102 mm (4 inches) interior diameter

These parameters ensured adequate airflow while accounting for normal filter loading during operation. The exhaust specifications were crucial for maintaining performance and preventing excessive exhaust gas temperatures.

Fuel System Options: From Mechanical to Electronic Control

The L10 evolved over its lifetime, offering three main fuel system configurations:

- Fixed Time: The original mechanical system

- STC (Step Timing Control): An improved mechanical system with variable timing

- CELECT (Cummins Electronic Control): The most advanced electronic control system

These systems represented the evolution of diesel injection technology during the L10’s production run. For operators, the key differences were in fuel efficiency, emissions, and maintenance requirements.

Fuel restriction specifications varied by configuration:

- CELECT: Max pump restrictions of 152 mm Hg (clean filter) / 254 mm Hg (dirty filter)

- STC/Fixed Time: Max restrictions of 102 mm Hg (clean) / 203 mm Hg (dirty)

- Return line restrictions (all types): Limited to 64 mm Hg, or 165 mm Hg with check valves

Natural Gas Variants: Ahead of Their Time

Cummins was ahead of the alternative fuel curve with the L10. In 1992, they introduced the L10G, powered by compressed natural gas (CNG) and targeted primarily at transit bus applications. This was later replaced by the L Gas Plus in 2001.

The natural gas engines offered comparable performance to their diesel counterparts:

- 280 hp (209 kW) with 900 lb-ft (1,220 N⋅m) of torque at 1300 RPM

- 300 hp (224 kW) with 860 lb-ft (1,166 N⋅m)

- 320 hp (239 kW) with 1,000 lb-ft (1,356 N⋅m)

These were governed at slightly lower speeds (2000-2100 RPM) compared to the diesel versions to optimize performance with gaseous fuel. For fleet operators looking to reduce emissions or take advantage of cheaper natural gas, these variants offered a compelling alternative without sacrificing the L10’s reliability.

Electrical System Requirements

Starting a large diesel engine requires significant electrical power, especially in cold weather. The L10 had specific requirements:

For 12-volt systems:

- 1280 cold cranking amps at 0°C (32°F)

- 1800 cold cranking amps at -18°C (0°F)

For 24-volt systems:

- 640 cold cranking amps at 0°C (32°F)

- 900 cold cranking amps at -18°C (0°F)

CELECT engines required a minimum of 6.5 volts at the three-pin connector for the Electronic Control Module (ECM) to function properly – particularly important for reliable starting in cold weather.

Real-World Applications: Where the L10 Excelled

The L10’s versatility made it a go-to choice across multiple industries:

- Transit buses: Both rigid and articulated designs

- Construction equipment: Including the Liebherr 954 excavator

- Commercial trucks: From delivery vehicles to long-haul applications

- Firetrucks: Where reliability is non-negotiable

- Motorhomes: Providing dependable power for recreational vehicles

- Marine applications: In various commercial and recreational boats

Its reputation for durability in demanding applications helped Cummins break into markets where they had previously struggled, particularly in the European transit bus sector.

| Application | Typical Power Rating | Key Advantage |

|---|---|---|

| Transit Bus | 250-330 hp | Horizontal mounting option, reliability in stop-go service |

| Commercial Truck | 300-400 hp | Balance of power and fuel economy |

| Construction | 280-300 hp | Superior torque for heavy loads |

| Firetruck | 300-350 hp | Reliability and consistent performance |

| Marine | 270-300 hp | Corrosion resistance and durability |

Maintenance Considerations for L10 Owners

If you’re operating an L10 engine, here are some key maintenance points to keep in mind:

- Oil changes: With such a large oil capacity, regular oil changes are crucial but less frequent than smaller engines. Follow Cummins recommendations based on your application.

- Cooling system maintenance: The cooling system is critical for the L10’s longevity. Regular inspections for leaks and proper coolant level/condition are essential.

- Air filtration: Given the strict intake restriction limits, regular air filter service is important, especially in dusty environments.

- Fuel system care: Keep an eye on fuel restrictions, particularly with the more sensitive electronic systems like CELECT.

- Valve adjustments: The OHV design requires periodic valve lash adjustments to maintain proper operation and efficiency.

Regular maintenance according to the Cummins service intervals will keep your L10 running strong for hundreds of thousands of miles.

Common Issues and Their Solutions

While the L10 was generally reliable, it did have some known issues:

- Oil consumption: Early models sometimes suffered from excessive oil consumption. Later production runs addressed this with improved piston rings and valve seals.

- Sealing problems: Some applications, particularly in the UK market, had issues with oil leaks. Updated gaskets and sealing procedures resolved most of these concerns.

- Fuel system durability: The mechanical fuel systems were generally more robust than the early electronic systems, though later CELECT systems improved reliability significantly.

- Cooling system failures: Given the importance of the cooling system, failures here could lead to significant engine damage. Preventative maintenance is key.

For operators of older L10 engines, a remanufactured unit can be a cost-effective way to extend the life of your equipment while addressing these common issues with updated components.

The L10 Legacy: Impact on Modern Cummins Engines

Though production ended in 1998, the L10’s influence continues. Its evolution into the M11 laid groundwork for the current Cummins lineup.

The lessons learned from the L10 program—particularly in electronic engine management, emissions control, and alternative fuel capability—directly influenced later designs like the ISM and X12 engines. Many of the engineers who worked on the L10 went on to develop Cummins’ modern engines.

For operators and mechanics familiar with the L10, this lineage means many maintenance practices and diagnostic approaches remain relevant with newer Cummins engines, making fleet transitions smoother.

Making the Most of Your L10 Engine

Whether you’re currently running an L10 or considering adding one to your fleet, here are some tips for maximizing performance and longevity:

- Follow the maintenance schedule: This sounds obvious, but it’s the single most important factor in engine longevity.

- Use genuine parts: Especially for critical components like fuel injectors and timing components.

- Monitor operating temperatures: The L10 performs best when running at proper temperature – not too hot, not too cold.

- Pay attention to oil analysis: Regular oil analysis can catch problems before they become serious.

- Consider upgrades: If running an older L10, certain updates and upgrades from later production runs can improve reliability and performance.

- Train your operators: Proper operating techniques, especially avoiding prolonged idling and proper warm-up procedures, can significantly extend engine life.

The Cummins L10 represented a perfect balance of power, reliability, and adaptability that made it a favorite across multiple industries. Its legacy continues in the modern Cummins lineup, and well-maintained L10 engines continue to provide dependable service decades after production ended.