Ever wondered what makes a Corvette’s heart beat so fiercely? Or why Camaro SS owners can’t stop grinning when they hit the gas? The answer lies in the LT1 – Chevrolet’s modern small-block masterpiece. This powerful 6.2L V8 isn’t just another engine; it’s the culmination of decades of engineering evolution packed with cutting-edge technology.

Whether you’re considering a C7 Corvette purchase, upgrading your project car, or simply appreciate automotive engineering, understanding the LT1’s capabilities will give you a deeper appreciation for this remarkable powerplant.

The LT1 Lineage: Three Generations of Power

The LT1 name carries serious weight in Chevrolet’s history, appearing across three distinct generations of small-block V8s.

The original LT-1 (note the hyphen) debuted in 1970 as a high-performance 350 cubic inch (5.7L) small-block. Found exclusively in Corvettes and Camaros, this first-generation engine packed an impressive 370 horsepower thanks to its 11.0:1 compression ratio and Holley 780 cfm 4-barrel carburetor. Production numbers were relatively small, and changing emissions regulations eventually reduced its output to 330 horsepower by 1971.

The second-generation LT1 (minus the hyphen) emerged between 1991-1997 as part of GM’s Gen II small block family. Powering the C4 Corvette’s final years, this 5.7L engine delivered 300 horsepower and 340 lb-ft of torque – respectable figures for the era that bridged the gap between classic small-blocks and modern designs.

Today’s Gen V LT1, introduced in 2014, represents the most dramatic evolution in the small block’s nearly 70-year history. While maintaining the iconic 90-degree cylinder angle and 4.400-inch bore centers that have defined Chevy small blocks since 1955, this modern incarnation incorporates technologies that would have seemed like science fiction to earlier generations of engineers.

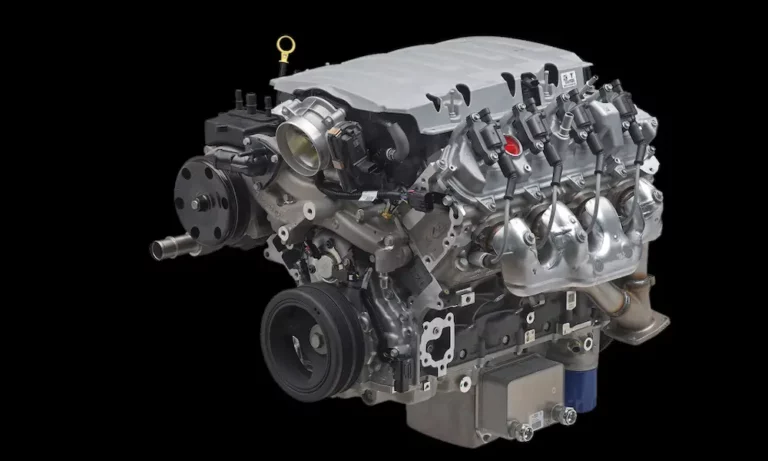

Gen V LT1 Architecture: The Building Blocks of Power

Block and Fundamental Dimensions

The modern LT1’s foundation starts with an all-aluminum block featuring:

- 4.065-inch bore

- 3.622-inch stroke

- 6.2 liters (376 cubic inches) total displacement

- 90-degree cylinder angle

- Traditional 4.400-inch bore centers

Unlike its predecessors, the Gen V block employs six-bolt nodular iron main bearing caps rather than conventional four-bolt designs, significantly increasing strength. Perhaps most important are the gusseted water jackets that dramatically improve the block’s rigidity and ability to handle high cylinder pressures.

This reinforced design allows the alloy LT1 block to handle up to 1000 horsepower in performance applications – roughly 40% more than the 700 horsepower limit typically associated with previous Gen IV LS aluminum blocks.

Cylinder Heads and Valvetrain

The LT1’s aluminum cylinder heads feature rectangular ports specifically optimized for direct injection with generous valve sizes:

- 2.130-inch intake valves

- 1.590-inch exhaust valves

These heads work with the direct injection system to create a highly efficient combustion process, enabling the LT1’s impressive 11.5:1 compression ratio while still operating on regular fuel under most conditions.

The valvetrain utilizes:

- Billet steel roller camshaft

- Investment-cast roller trunnion rocker arms (1.81:1 ratio)

- 0.561-inch intake lift

- 0.531-inch exhaust lift

- 242° intake duration / 244° exhaust duration (measured at 0.050-inch lift)

This setup provides excellent breathing capacity up to the engine’s 6,600 RPM redline.

Rotating Assembly

The LT1’s internals are built for both performance and durability with:

- Forged steel crankshaft

- Forged powdered metal connecting rods

- Hypereutectic aluminum pistons

This combination creates an optimal balance of strength, weight, and thermal stability – essential for an engine designed to deliver both track-capable performance and everyday reliability.

Advanced Technologies: Modern Engineering Magic

Direct Fuel Injection

Perhaps the most significant technological leap in the Gen V LT1 is its direct fuel injection system. Unlike conventional port injection that sprays fuel into the intake port, the LT1 delivers precisely measured fuel directly into the combustion chamber at pressures exceeding 2,000 psi.

This high-pressure delivery system requires specialized components:

- Engine-mounted high-pressure direct injection fuel pump

- Conventional in-tank supply pump

- Sophisticated fuel injectors capable of withstanding combustion chamber conditions

The benefits are substantial:

- More precise fuel delivery

- Better fuel atomization

- Improved combustion efficiency

- Enhanced power output

- Better fuel economy

- Reduced emissions

Active Fuel Management (AFM)

When full power isn’t needed, the LT1’s Active Fuel Management system selectively deactivates four cylinders, effectively transforming the 6.2L V8 into a 3.1L V4 during light-load cruising. The system:

- Deactivates valve lifters on specific cylinders

- Keeps both intake and exhaust valves closed

- Traps an air charge within those cylinders to minimize pumping losses

The transition between eight and four-cylinder operation happens seamlessly, with most drivers unable to detect when the system activates. This technology improves fuel economy by approximately 5-7% compared to equivalent non-AFM engines.

Variable Valve Timing (VVT)

The LT1’s variable valve timing system optimizes camshaft timing across various operating conditions using a cam phaser that can advance or retard timing based on:

- Engine speed

- Engine load

- Operating conditions

At idle and low speeds, the system adjusts timing to improve stability and emissions. At higher RPMs, it optimizes for maximum power production. Working continuously with the engine’s electronic control module, VVT provides benefits across the entire operating range without the compromises typically associated with fixed camshaft timing.

Enhanced Thermal Management

The LT1’s cooling system represents a significant improvement over earlier small-blocks with revised coolant flow patterns that:

- Provide more uniform cylinder head temperatures

- Reduce hot spots that could cause detonation

- Target cooling for exhaust valves and other critical areas

- Maintain optimal operating temperatures even under severe conditions

This sophisticated cooling architecture is crucial given the engine’s high compression ratio and performance potential, ensuring consistent output whether in casual driving or track use.

Performance Specifications: The Numbers That Matter

In factory form, the Gen V LT1 delivers impressive performance figures:

- 455 horsepower at 6,000 RPM

- 460 lb-ft of torque at 4,600 RPM

These numbers represent excellent specific output for a naturally aspirated, production pushrod V8. More impressive is the power delivery – remarkably linear with substantial torque throughout the operating range and a broad plateau near peak torque that enhances real-world drivability.

The 11.5:1 compression ratio contributes significantly to the engine’s efficiency and power output. While this compression level would typically demand premium fuel, the LT1’s sophisticated direct injection and combustion control systems allow it to operate effectively on regular fuel under most conditions.

In stock form, LT1-powered vehicles deliver impressive performance:

- Corvette Stingray: 0-60 mph in 3.8 seconds, quarter-mile in low 12-second range

- Camaro SS: 0-60 mph in low 4-second range, quarter-mile in high 12-second range

For enthusiasts seeking more, the LT1’s robust design provides an excellent foundation for modifications. With appropriate supporting upgrades, the reinforced block structure can reliably handle up to 1,000 horsepower – a significant increase over previous generations.

| Performance Metric | LT1 Specification |

|---|---|

| Horsepower | 455 hp @ 6,000 RPM |

| Torque | 460 lb-ft @ 4,600 RPM |

| Redline | 6,600 RPM |

| Compression Ratio | 11.5:1 |

| Fuel Requirement | Regular (premium recommended for maximum performance) |

| Weight (approx.) | 465 lbs (wet) |

| Modification Potential | Up to 1,000+ hp with supporting modifications |

Vehicle Applications: Where You’ll Find the LT1

Production Vehicles

The Gen V LT1 made its production debut in the 2014 Chevrolet Corvette Stingray (C7), serving as the standard engine for America’s flagship sports car. In this application, the engine produced 455 horsepower and 460 lb-ft of torque (460 hp with the optional performance exhaust).

Some Corvette variants featured a dry-sump oiling system for improved oil control during high-g cornering. The LT1 powered the Corvette Stingray throughout the C7’s production run (2014-2019) and the Grand Sport model introduced for 2017.

The LT1 expanded to the Chevrolet Camaro lineup with the sixth-generation model for 2016, where it served as the engine for the SS performance variant. The Camaro implementation used effectively the same engine as the Corvette but employed a conventional wet-sump oiling system. The LT1 remained the standard engine in the Camaro SS through the end of the sixth-generation’s production in 2023.

Crate Engine Availability

For custom builds and restorations, the LT1 is available as a crate engine through Chevrolet Performance. These come in both wet-sump and dry-sump configurations to accommodate different installation requirements and performance goals.

Crate engines come assembled with high-pressure direct-injection fuel pumps installed but require additional electronics for operation. Controller kits are available to provide the necessary engine management systems.

Chevrolet Performance offers these engines specifically for pre-1976 street vehicles or off-road applications, with pricing typically in the $9,500-$11,500 range depending on configuration and included accessories.

| Vehicle | Years | Power Output | Oiling System |

|---|---|---|---|

| Corvette Stingray | 2014-2019 | 455-460 hp | Dry-sump option |

| Corvette Grand Sport | 2017-2019 | 460 hp | Dry-sump |

| Camaro SS | 2016-2023 | 455 hp | Wet-sump |

| Crate Engine | Current | 455 hp | Wet or dry-sump available |

LT1 vs. LS: Evolution Not Revolution

The transition from the LS series to the LT1 represents significant evolution in GM’s small block engine family, bringing numerous technological improvements while maintaining the fundamental architectural elements that made the LS series successful.

While sharing the same bore spacing, deck height, and general layout as the LS engines, the numerous technological advancements result in a distinctly different engine with improved performance characteristics.

Key differences from LS engines:

- Direct fuel injection (vs. port injection in LS)

- Revised cooling system architecture

- Enhanced block structure with improved strength

- Active Fuel Management system

- Higher compression ratio

- Revised combustion chamber design

- Piston-cooling oil jets

Despite these differences, the LT1 maintains sufficient commonality with the LS family to leverage the extensive aftermarket support and development experience gained over decades of LS production.

Tuning and Modification Potential

The LT1’s robust design provides an excellent foundation for performance builds. Common modifications include:

Bolt-on Modifications

- Cold air intake systems: 10-15 hp gain

- Header-back exhaust systems: 15-25 hp gain

- Performance camshafts: 30-50+ hp gain

- Ported cylinder heads: 20-40 hp gain

Advanced Modifications

- Forced induction (supercharger/turbo): 150-400+ hp gain

- Stroker kits to increase displacement

- Standalone engine management systems

- E85 fuel conversion for increased power potential

When properly built, modified LT1 engines can reliably produce over 1,000 horsepower – a testament to the inherent strength of the base architecture and the improvements made over previous generations.

The Future of the LT1 Platform

The LT1 has already begun to evolve, with the LT2 engine in the C8 Corvette Stingray representing a refined version of the same fundamental architecture. More specialized variants like the flat-plane crank LT6 in the Corvette Z06 push the concept in new directions.

These continued developments suggest that GM remains committed to the small-block V8 configuration even as the automotive industry transitions toward electrification. The LT1’s successful combination of traditional architecture with modern technology demonstrates substantial room for innovation within this venerable engine family, ensuring its relevance for years to come.

Whether in factory form or as the foundation for a high-performance build, the LT1 stands as one of the most impressive production V8 engines available today – a modern interpretation of the small-block formula that has defined American performance for nearly seven decades.