Your Chevy just flashed “Engine Power Reduced” on the dashboard, and suddenly you’re crawling along like you’re towing a house. Don’t panic—this isn’t random. Your car’s computer just switched to safe mode because something’s wrong. We’ll walk you through what triggers this warning, how to diagnose it yourself, and what fixes actually work. Stick around—you might save yourself a dealership trip.

What Does “Engine Power Reduced” Actually Mean?

When your Chevy’s warning system kicks in, it’s not trying to ruin your day. The Engine Control Module (ECM) detected a mismatch between what it commanded and what your sensors reported back. Think of it as your car’s emergency brake for the engine.

The system cuts throttle response to about 30-40% of normal. You’ll still move, but acceleration feels like you’re driving through molasses. This “limp-home mode” protects your engine from catastrophic damage when something in the powertrain goes haywire.

Your ECM monitors hundreds of inputs every second. When sensor signals don’t match up—like when your accelerator pedal says “floor it” but the throttle position sensor says “barely open”—the system assumes the worst and limits power. It’s frustrating, but it beats destroying your engine.

The Electronic Throttle System: Your Car’s Achilles Heel

Modern Chevys ditched the old cable throttle years ago. Now you’ve got drive-by-wire, where your gas pedal is just a glorified suggestion box. The Accelerator Pedal Position (APP) sensor reads your foot movement and sends voltage signals to the ECM.

Here’s where it gets technical: your pedal has two or three separate sensors that work together. One might read 0.5V to 4.5V while the other reads 0.25V to 2.25V. If these signals drift apart by more than 10%, your ECM freaks out and throws you into limp mode.

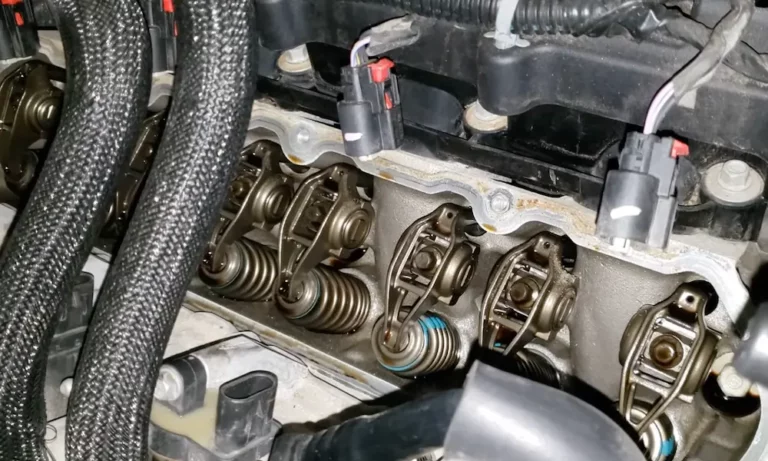

The throttle body itself uses the same redundant setup. Two Throttle Position Sensors (TPS) constantly verify the throttle plate’s actual position. When the motor tries to open the throttle but the sensors disagree about where it is, you get the dreaded power reduction.

Common Trouble Codes You’ll See

| Code | What It Means | Failed Part | Why It Happens |

|---|---|---|---|

| P2135 | TPS Sensors Don’t Match | Throttle Body | Carbon buildup or sensor failure |

| P2138 | APP Sensors Out of Sync | Accelerator Pedal | Moisture in connector or worn tracks |

| P1516 | Throttle Won’t Move Right | TAC Module/Motor | Heat damage or mechanical binding |

| P0121 | TPS Range Problem | Throttle Body | Dirty throttle plate restricting movement |

| P0299 | Turbo Underboost | Intercooler Hose | Boost leak in turbocharged models |

Why Carbon Buildup Is Your Enemy

The number one mechanical cause of reduced engine power on Chevy Silverados and other models? Dirty throttle bodies. Your Positive Crankcase Ventilation (PCV) system recycles oil vapors back through the intake. Sounds eco-friendly until those vapors condense on your throttle plate.

Over 50,000 to 100,000 miles, you’ll build up a crusty layer of carbon that makes the throttle plate stick. The actuator motor has to work harder to push through the gunk. Your ECM monitors motor current—when it spikes because the motor’s struggling, the computer thinks the throttle’s failing and cuts power.

Here’s the kicker: this happens gradually. You won’t notice the buildup until one day the motor can’t overcome it. Then boom—”Engine Power Reduced” appears and you’re stuck.

Model-Specific Nightmares You Should Know About

Chevy Malibu: The Recall King

The 2013-2022 Malibu wins the prize for most reduced power complaints. Early models (2013-2015) had overly sensitive ECM calibrations. GM issued a software recall (NHTSA Campaign 15V164) to fix it—basically telling the computer to chill out about minor sensor variations.

The 2016-2022 Malibus with 1.5L turbos have a different problem: the Charge Air Cooler outlet tube separates under boost. When that pipe pops off, you lose all turbo pressure. The engine goes into limp mode to protect the turbo from overspeeding. You’ll get a P0299 code and basically zero acceleration.

Silverado: Ground Yourself Before You Wreck Yourself

Silverado owners know the drill: check your grounds first. The ground strap on the back of the engine block corrodes like crazy, especially in salt-belt states. When that connection goes bad, your sensor voltages float and you’ll throw random codes.

The Throttle Actuator Control (TAC) module on the passenger firewall also fails from heat. Multiple codes (P0120, P0220, P2135) appearing together usually means the TAC module’s toast. It’s a $200-$400 part with about an hour of labor.

Cruze: The PCV Disaster

The 1.4L turbo Cruze has a fatal flaw in the PCV system. There’s an orange check valve in the intake manifold that loves to get sucked into the engine. When that happens, crankcase pressure spikes and ruptures a diaphragm inside the valve cover.

This creates a massive vacuum leak. You’ll hear a high-pitched whistle, the engine idles rough, and you’ll see a P0171 lean code. The ECM limits power because it can’t maintain the right air-fuel ratio. Fix requires a new valve cover—about $150 in parts if you DIY it.

How Electrical Gremlins Trigger False Alarms

Your APP and TPS sensors operate on millivolt differences. Anything that creates electrical noise or resistance in the ground circuit will corrupt those signals. We’re talking about voltage variations as small as 0.1V causing problems.

Corroded grounds are the sneakiest culprits. Battery negative to frame, engine block to firewall—these connections oxidize over time. When resistance builds up, your sensors lose their voltage reference point and send garbage data.

Wiring harness chafing causes intermittent faults that’ll drive you crazy. On Equinox and Traverse models, the harness near the fan shroud rubs through and creates short circuits. You’ll get the warning light randomly—usually when you hit a bump that flexes the harness.

Beyond the Throttle: Other Power-Killing Problems

Overheating Kills Power Too

When your coolant temp hits 240°F to 250°F, the ECM initiates “Engine Overheated – Reduced Power” mode. The computer will actually deactivate half your cylinders, alternating between banks. The dead cylinders pump air to cool the block while you limp to safety.

Check your coolant level first. Low coolant means bad temp readings and overheating. A stuck thermostat or failed water pump will also trigger this. Don’t ignore it—continued overheating warps cylinder heads.

Clogged Cats Choke Performance

A plugged catalytic converter creates backpressure that suffocates your engine. The computer sees that manifold pressure isn’t dropping during deceleration and figures something’s wrong. Power gets cut to prevent valve damage.

You can test this: remove the upstream O2 sensor and drive it. If power returns, your cat’s the problem. On turbocharged models, a clogged converter will also trigger underboost codes.

Fuel System Failures

High-pressure fuel pumps fail on direct-injection engines. When fuel pressure drops below spec, you’ll get a P228C code and reduced power mode. This is common on E85-compatible engines where ethanol corrodes the pump internals.

Diagnosing the Problem Like a Pro

Skip the parts cannon approach. Get an OBD-II scanner and pull those codes. But don’t just read the code—you need live data to see what’s actually happening.

Graph your APP1 and APP2 sensor voltages while slowly pressing the pedal with the engine off. The lines should be smooth and parallel. Any spikes, flat spots, or sudden drops mean the pedal’s worn out. Same test for TPS1 and TPS2 at the throttle body.

| Sensor | Idle Voltage | Full Throttle | Common Failure Pattern |

|---|---|---|---|

| TPS1 | 0.5V | 4.5V | Gradual drift from carbon |

| TPS2 | 4.5V | 0.5V | Inverse failure (short circuit) |

| APP1 | 0.5V | 4.5V | Dead spots in first 25% of travel |

| APP2 | 0.25V | 2.25V | Half-voltage correlation error |

Check your grounds with a multimeter. You should see less than 0.1 ohms resistance between battery negative and engine block, and between block and firewall. Anything higher means corrosion.

Fixing It Without Breaking the Bank

The $15 Fix: Clean Your Throttle Body

Remove the throttle body completely—don’t spray cleaner into it while installed. Use throttle body cleaner and a soft cloth to wipe the bore and plate. Never spray into the motor housing or electrical connector.

After cleaning, you’ll need to do an idle relearn procedure. Your ECM had learned to compensate for the carbon buildup. Now that it’s clean, the computer needs to relearn the correct idle airflow.

The Idle Relearn Process

- Turn ignition ON (engine off) for 60 seconds

- Turn ignition OFF for 60 seconds

- Start engine and idle in Park for 3 minutes

- Turn engine OFF for 60 seconds

- Restart and idle for another 3 minutes

- Drive at highway speeds (55+ mph) with several decelerations

Your idle should settle to around 600-700 RPM after this. If it stays high (1,200-1,500 RPM) or the car goes back into reduced power, you missed a step or the throttle body needs replacement.

When You Need New Parts

Throttle bodies run $175-$450 depending on your model. Labor’s about 1-2 hours at a shop. Accelerator pedals cost $120-$350 with 30-60 minutes of labor. That’s considerably cheaper than letting a mechanic throw parts at the problem.

Check for extended warranties before you pay. GM issued special coverage N182188250 for Malibu APP sensors—10 years or 150,000 miles. The throttle body and pedal are also covered under the Federal Emissions Warranty (8 years/80,000 miles) in many cases.

The Ground Fix That Saves Thousands

Find the ground straps: one on the back of the engine block to the firewall, another from battery negative to the frame. Remove them, wire-brush the contact points until they’re shiny, and reinstall with new bolts. This $0 fix has solved countless “unfixable” reduced power issues.

Why StabiliTrak Freaks Out Too

See “Service StabiliTrak” alongside your power reduction warning? That’s not a separate problem. StabiliTrak needs to cut engine power during a skid to regain traction.

If the ECM can’t trust the throttle position sensors, it can’t guarantee it can close the throttle when stability control demands it. So it shuts down StabiliTrak completely until you fix the throttle issue. Fix one problem, both warnings disappear.

What It’ll Cost You

Here’s the brutal truth about repair costs:

| Repair | Parts Cost | Labor Hours | Total Cost |

|---|---|---|---|

| Throttle Body Cleaning | $10-$15 | DIY | $10-$15 |

| Ground Cleaning | $0 | DIY | $0 |

| Throttle Body Replacement | $175-$450 | 1-2 hrs | $275-$750 |

| Accelerator Pedal | $120-$350 | 0.5-1 hr | $170-$500 |

| TAC Module | $200-$400 | 1 hr | $300-$550 |

| High-Pressure Fuel Pump | $350-$600 | 2-3.5 hrs | $550-$1,100 |

| ECM Reflash | N/A | 1 hr | $100-$180 |

Always check for TSBs (Technical Service Bulletins) before paying for anything. GM has issued software updates and extended warranties for many of these issues. Your “expensive repair” might be covered for free.

Preventing Future Problems

Clean your throttle body every 50,000 miles. Use Top Tier gasoline with better detergents to minimize carbon buildup. Inspect and clean ground connections annually, especially if you live where they salt the roads.

For turbocharged models, check all intercooler clamps and hoses twice a year. A $2 clamp that’s slightly loose will cause a boost leak that triggers limp mode. On Cruze 1.4Ts, replace the PCV check valve preventatively around 100,000 miles—it’s $20 versus $400 for a new valve cover after it fails.

The Bottom Line

The “Engine Power Reduced” warning isn’t a death sentence for your Chevy. It’s usually a dirty throttle body, bad ground connection, or failed sensor. Start with the free fixes—clean your grounds and throttle body. Pull those codes and check live sensor data before replacing parts.

Most importantly, don’t ignore it. Continuing to drive in limp mode won’t damage your engine directly, but the underlying problem might. A simple $15 cleaning now beats a $1,000 repair later.

Your Chevy’s trying to protect itself. Listen to it, diagnose it properly, and you’ll be back to full power without emptying your wallet at the dealership.