Thinking about the reliability of your GM truck or SUV with a 4.3 Vortec engine? You’ve probably heard mixed opinions – some swear by these workhorses while others complain of persistent issues. This in-depth guide explores the most common 4.3 Vortec engine problems, when they typically occur, and what you can do to fix them or prevent them entirely.

The Evolution of the 4.3 Vortec Engine

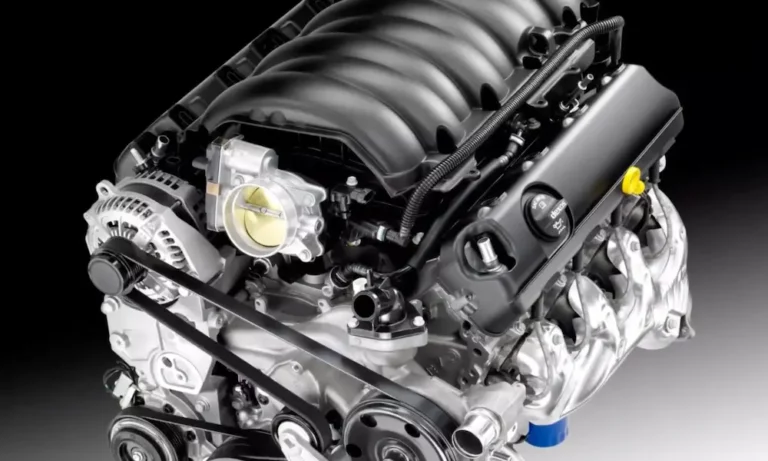

GM’s 4.3L Vortec V6 has powered trucks and SUVs for nearly three decades, from 1985 to 2014. Based on Chevy’s small block V8 (essentially a 350 V8 with two cylinders removed), the engine shares many components with its larger sibling.

Throughout its production, the 4.3 Vortec went through several important iterations:

| Variant | Years | Key Features | Horsepower |

|---|---|---|---|

| LB1 | 1985-1986 | Carburetor | 155 hp |

| LB4 | 1985-1995 | Throttle-body injection | 160-170 hp |

| L35 | 1992-2002 | Central Sequential Fuel Injection, balance shaft | 180-200 hp |

| LF6 | 1996-2002 | Similar to L35, used in S-series trucks | 180-200 hp |

| LU3/LG3 | 2003-2014 | Multi-port fuel injection | 190-200 hp |

Each variant has its unique quirks and common issues, but a few problems are consistent across most 4.3 Vortec engines.

Intake Manifold Gasket Failure

This is perhaps the most notorious problem with 4.3 Vortec engines, especially in the LB4 and L35 variants produced between 1985 and 2002.

Symptoms of Intake Manifold Gasket Failure

- Engine misfires and rough running

- Coolant leaks (external or internal)

- Engine overheating

- Low coolant warnings

- Milky oil (when coolant mixes with oil)

- Poor acceleration

- Check engine light with lean/rich condition codes

Why It Happens

The intake manifold gaskets on these engines are made from plastic materials that deteriorate under high heat and pressure. These gaskets typically fail between 100,000-150,000 miles, though some fail as early as 50,000 miles.

The gaskets serve two critical functions: sealing engine vacuum and containing coolant passages. When they fail, coolant can leak externally or internally into the oil system.

Repair Costs and Solution

Replacing intake manifold gaskets typically costs between $790-$961, with labor making up about half the expense. The job requires removing the distributor, upper intake manifold, and various accessories to access the lower intake manifold.

Many mechanics recommend upgrading to improved aftermarket gaskets rather than using OEM replacements, as they tend to last longer.

Central Port Injection System (“Spider”) Problems

L35 and LF6 engines (1996-2002) use a unique fuel delivery system called Central Port Fuel Injection or “spider” injection. This system has a central distribution unit with six tubes leading to individual cylinders.

Symptoms of Spider Injection Failure

- Cylinder misfires (P0300-P0306 codes)

- Hard starting or long cranking times

- Poor idle but okay performance at higher RPMs

- Flooding conditions (engine only runs with fuel pump relay disconnected)

Why It Happens

The spider system is prone to developing leaks at the pressure regulator and fuel lines. The poppet valves at each cylinder can also become clogged or fail to operate properly.

Repair Options

You have three main options when dealing with spider injection problems:

- Rebuild the existing system ($650-$800)

- Replace with an updated version of the same system ($750-$900)

- Upgrade to the more reliable Multi-Port Fuel Injection system ($800-$1,000)

Many owners opt for the MPFI upgrade since it eliminates the problematic design entirely and offers improved reliability and performance.

Idle Control Valve and Throttle Position Sensor Failures

These issues affect virtually all 4.3 Vortec variants and are among the most commonly reported problems.

Symptoms of ICV/TPS Failure

- Rough or unstable idle

- Engine stalling

- Hesitation during acceleration

- Hard shifting (in automatic transmissions)

- Poor throttle response

- Check engine light (often P0122 for TPS issues)

Why It Happens

Both sensors mount directly to the throttle body and control airflow into the engine. They become contaminated and degraded over time due to the large volume of air passing through them.

Repair Costs

This is one of the more affordable repairs for 4.3 Vortec engines, typically costing between $130-$270 including parts and labor. The components are easily accessible and can sometimes be cleaned rather than replaced.

Distributor Cap and Rotor Issues

The distributor is another common failure point across all Vortec variants, though the issue is particularly problematic due to the plastic construction used.

Symptoms of Distributor Problems

- Engine misfires

- Misfire codes (P0300-P0306)

- Hard starting or no-start conditions

- Poor engine performance

- Rough running

Why It Happens

The distributor sits in a high-heat area with poor ventilation, causing the plastic cap to warp over time. This warping allows moisture and contaminants to enter and can cause the rotor to rub against the cap.

The Smart Fix

Instead of replacing with another plastic distributor, upgrade to an aluminum housing distributor. This costs roughly the same ($75-$160) but provides significantly improved durability and heat resistance.

Excessive Oil Consumption and AFM Problems

Later engines (2003-2014 LU3/LG3) equipped with Active Fuel Management (AFM) often experience oil consumption issues.

Symptoms of AFM-Related Problems

- Burning 2-3 quarts of oil between changes

- Lifter collapse or failure

- Knocking or ticking sounds

- Reduced power

- Check engine light

Why It Happens

AFM systems deactivate cylinders under light load to improve fuel economy. However, the deactivated cylinders continue to receive oil flow without combustion occurring, leading to oil being drawn into the combustion chamber. Additionally, the complex AFM lifters can stick or fail mechanically.

The Permanent Solution

Many owners install an AFM delete kit ($500-$900 including installation), which disables the system entirely. This significantly reduces oil consumption and improves long-term reliability.

Engine Knock Issues

L35 and LF6 variants (1996-2002) sometimes experience engine knock problems, which create a distinctive “pinging” sound during operation.

Symptoms of Engine Knock

- Knocking or pinging sounds, especially under load

- Reduced power

- Poor acceleration

- Engine damage if left unchecked

Potential Causes

While engine knock can result from various factors (low-grade fuel, carbon buildup, bad spark plugs), the specific issue in these 4.3 Vortec variants often relates to piston wear. Most successful repairs involve replacing the pistons, which is a major undertaking requiring significant engine disassembly.

Preventive Maintenance for 4.3 Vortec Engines

Despite these problems, 4.3 Vortec engines can easily reach 250,000-300,000 miles with proper maintenance. Here’s how to maximize reliability:

Regular Maintenance

- Change oil every 3,000-5,000 miles (more frequently for AFM engines)

- Use high-quality synthetic oils for better protection

- Replace the coolant every 30,000 miles

- Inspect the intake manifold gaskets at 80,000 miles and replace if needed

- Upgrade to an aluminum distributor during first replacement

- Clean ICV and TPS sensors periodically

Proactive Upgrades

- Consider MPFI conversion for engines with spider injection

- Install an AFM delete kit for affected engines

- Use improved aftermarket intake manifold gaskets

- Upgrade to high-quality ignition components

Is the 4.3 Vortec a Reliable Engine Overall?

Despite the issues we’ve covered, the 4.3 Vortec is generally considered reliable. The engine block and internal components are exceptionally robust, and most problems affect peripheral systems rather than core engine components.

The key is addressing known weak points proactively rather than waiting for failures. When properly maintained, these engines deliver exceptional service life and reliability, which explains their enduring popularity among truck and SUV owners.

| Engine Component | Expected Lifespan | Common Failure Points |

|---|---|---|

| Engine Block | 250,000+ miles | Rarely fails |

| Intake Manifold Gaskets | 80,000-150,000 miles | Common failure point |

| Distributor | 100,000 miles | Plastic cap warping |

| Spider Injection | 100,000-150,000 miles | Leaks, pressure regulator issues |

| ICV/TPS Sensors | 80,000-120,000 miles | Contamination, wear |

| AFM System | Varies widely | Lifter failure, oil consumption |

The Bottom Line on 4.3 Vortec Reliability

The GM 4.3L Vortec strikes a good balance of power, efficiency, and durability. Its problems are generally predictable and manageable from both technical and financial perspectives. With proper care and attention to known weak points, this engine can deliver exceptional service life.

Understanding which specific variant you have and its common issues allows you to make informed maintenance decisions and budget appropriately for expected repairs. For many owners, the durability of the core engine components more than makes up for the peripheral issues that might arise.

Have you experienced any of these common 4.3 Vortec problems? Share your experience in the comments below!