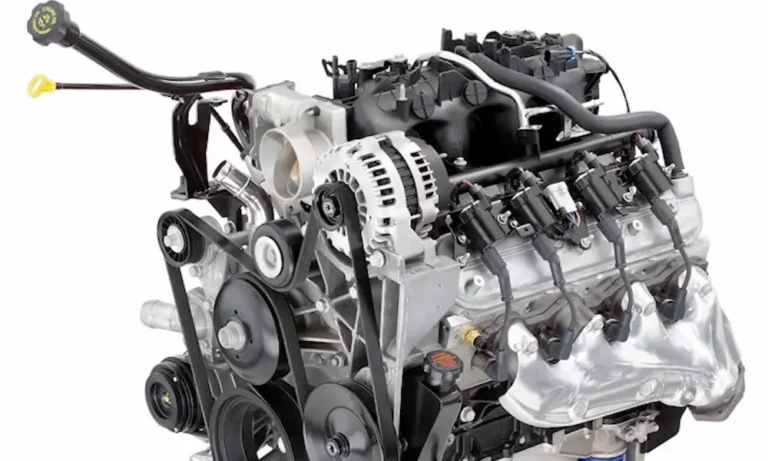

Ever wondered what makes the LQ9 engine special among GM’s lineup? This powerful 6.0L V8 has developed quite the following among truck enthusiasts and performance builders alike. Whether you’re considering a swap, rebuilding one, or just plain curious about what’s under the hood of certain GM trucks and SUVs from the early 2000s, you’ve come to the right place.

What Is the LQ9 Engine?

The LQ9 is a 6.0-liter V8 engine developed by General Motors as part of their legendary LS engine family. Often marketed as the “Vortec HO 6000” or “VortecMAX,” this powerplant ruled GM’s premium truck and SUV lineup from 2002 to 2007.

What sets it apart from similar engines like the LQ4 is its higher compression ratio and flat-top pistons, which squeeze out more horsepower and torque. Think of it as the LQ4’s more athletic sibling—same family, but with more muscle.

LQ9 Engine Specs: The Basics

Let’s break down the fundamental specs that define the LQ9:

| Specification | Details |

|---|---|

| Displacement | 6.0L / 364 cubic inches |

| Configuration | 90° V8 |

| Bore | 4.000 inches |

| Stroke | 3.622 inches |

| Compression Ratio | 10.1:1 |

| Horsepower | 345 hp @ 5,200 rpm |

| Torque | 380 lb-ft @ 4,000 rpm |

| Block Material | Cast iron |

| Head Material | Aluminum |

| Production Years | 2002-2007 |

These numbers tell an important story: the LQ9 was designed for trucks that needed serious power without sacrificing reliability. With 345 horsepower and a meaty 380 lb-ft of torque, it delivered approximately 20 more horses than the standard LQ4 engine, thanks primarily to that higher compression ratio.

The Heart of the Beast: Block Specifications

The foundation of any engine is its block, and the LQ9’s is particularly robust. Made from cast iron, this block was built to handle serious power and torque for years of hard work.

Key block features include:

- Cast iron construction for superior strength and durability

- Common casting numbers: 12551364, 12573581, 12577184

- Deck height of 9.230-9.240 inches

- Bore spacing of 4.400 inches

- A robust 6-bolt main cap design

That 6-bolt main cap design deserves special attention. Unlike standard 4-bolt mains, the additional bolts provide extra clamping force to keep the crankshaft firmly in place under high-load conditions. This feature makes the LQ9 block particularly attractive for performance builds and engine swaps where additional power is the goal.

Inside the Engine: Rotating Assembly

Pop the hood on an LQ9’s internals and you’ll find a rotating assembly built for both performance and longevity:

- Hypereutectic cast aluminum pistons with a flat-top design

- Full-floating wrist pins measuring 0.9429/0.9431 inches

- Powdered metal connecting rods in an I-beam configuration

- 6.098-inch connecting rod length

- Cast iron crankshaft with 2.559-inch main journals

- 24X reluctor wheel for precise timing

The flat-top pistons are particularly noteworthy as they’re a key component in achieving the 10.1:1 compression ratio that gives the LQ9 its power advantage. These pistons have zero cc volume in their design, maximizing compression without venturing into territory that would require premium fuel.

Breathing Room: Cylinder Head Specifications

Up top, the LQ9 sports aluminum cylinder heads that help reduce overall engine weight while improving heat dissipation. These heads feature GM’s familiar “cathedral port” design, characteristic of Gen III LS engines.

Head specifications include:

- Casting numbers: 035, 317

- 71cc combustion chambers

- Cathedral-shaped intake ports with 210cc runner volume

- D-shaped exhaust ports with 75cc runner volume

- Valve sizes: 2.000-inch intake, 1.550-inch exhaust

These aluminum heads provide a good balance between airflow and torque production, perfectly suited to the truck and SUV applications the LQ9 was designed for. The cathedral ports may not flow as well as the rectangular ports found on later LS3 heads, but they deliver excellent low and mid-range torque—exactly what you want when towing or hauling.

Advanced Features: More Than Just Displacement

The LQ9 wasn’t just about brute force—it incorporated several advanced technologies that were innovative for truck engines of that era:

- Variable valve timing for optimized performance across the RPM range

- Active Fuel Management (cylinder deactivation) on some applications

- Electronic throttle control for precise throttle response

- Sequential fuel injection for improved efficiency

These technologies helped the LQ9 balance its considerable power output with reasonable fuel economy—a growing concern in the mid-2000s as gas prices began to climb. The engine offered truck owners significant power without completely sacrificing efficiency.

Where You’ll Find It: LQ9 Vehicle Applications

The LQ9 engine was reserved for GM’s premium and performance-oriented trucks and SUVs. You’ll find it under the hood of these vehicles:

- 2002-2006 Cadillac Escalade AWD

- 2005-2006 Cadillac Escalade 2WD

- 2002-2006 Cadillac Escalade EXT

- 2003-2006 Cadillac Escalade ESV

- 2003-2007 Chevrolet Silverado SS & High Output Edition

- 2005-2006 GMC Sierra Denali

- 2006-2007 Chevrolet Silverado Classic VortecMAX

- 2006-2007 GMC Sierra Classic VortecMAX

Interestingly, all these vehicles came equipped with 4.10:1 rear axle ratios to maximize the performance potential of the LQ9 engine. This gearing helped these heavy trucks and SUVs feel surprisingly quick off the line while maintaining good towing capability.

The LQ9 vs. LQ4: Sibling Rivalry

The LQ9 is often compared to its close relative, the LQ4. Both are 6.0L truck engines from the LS family, but with some important differences:

| Feature | LQ9 | LQ4 |

|---|---|---|

| Compression Ratio | 10.1:1 | 9.4:1 |

| Piston Design | Flat top | Dish top |

| Horsepower | 345 hp | 325 hp |

| Torque | 380 lb-ft | 370 lb-ft |

| Applications | Premium trucks/SUVs | Standard trucks/SUVs |

These differences might seem minor on paper, but they translate to a noticeable improvement in performance. The LQ9’s higher compression ratio and flat-top pistons are responsible for most of its power advantage, making it the more desirable engine for enthusiasts.

Performance Potential: Unleashing the Beast

One reason the LQ9 remains popular today is its tremendous potential for modifications. The robust iron block and respectable aluminum heads provide an excellent foundation for building serious power.

Common performance upgrades include:

- Cam swaps (the factory cam is quite mild)

- Cylinder head porting or complete head upgrades

- Intake manifold upgrades

- Headers and exhaust improvements

- Forced induction (superchargers or turbochargers)

With minimal modifications, an LQ9 can easily produce 400+ horsepower while maintaining excellent reliability. Push things further with forced induction, and 500-600 horsepower is well within reach without compromising the block’s integrity.

For engine swap enthusiasts, the LQ9 offers several advantages:

- Widely available from salvage yards

- Strong bottom end that can handle significant power

- Compatibility with the vast LS aftermarket

- More affordable than an LS3 or newer engine

Common Issues and Reliability

While the LQ9 is generally considered quite reliable, no engine is without potential issues. Here are a few things to watch for:

- Intake manifold gasket leaks (especially on higher mileage engines)

- Oil consumption in some engines after 150,000+ miles

- Occasional throttle body issues

- Potential valve spring failures at high RPM when modified

Despite these occasional issues, the LQ9 earns high marks for durability. Many examples have surpassed 200,000 miles with proper maintenance, and the engine’s truck-duty design provides ample headroom for performance modifications without sacrificing reliability.

Identifying an LQ9 Engine

If you’re hunting for an LQ9 for your project, here’s how to make sure you’ve got the right engine:

- Check the engine code on the block (usually stamped on a pad near the passenger side front cylinder)

- Look for the casting numbers on the block (12551364, 12573581, or 12577184)

- Examine the pistons—flat tops indicate an LQ9, while dished pistons suggest an LQ4

- Verify the heads have casting numbers 035 or 317

Don’t rely solely on what the seller tells you, as LQ4 engines are sometimes mislabeled as LQ9s in the secondhand market.

Finding Replacement Parts

One of the LQ9’s greatest strengths is parts availability. As part of the LS engine family, components are widely available from both OEM and aftermarket sources.

For stock rebuilds, you can source:

- Gasket sets from any major parts retailer

- Bearings, rings, and seals from standard engine suppliers

- Factory replacement components through GM dealers

For performance builds, the aftermarket support is tremendous:

- Camshafts from companies like Comp Cams, Brian Tooley Racing, and Texas Speed

- Cylinder heads from manufacturers like Trick Flow, AFR, and GM Performance

- Intake manifolds from FAST, Holley, and others

- Complete rotating assemblies from numerous performance vendors

This parts availability ensures the LQ9 will remain relevant and rebuildable for decades to come.

The Legacy of the LQ9 Engine

While production ended in 2007, the LQ9’s influence continues. It helped establish GM’s reputation for building powerful, reliable truck engines and set the stage for later developments like the L92 and L94 engines.

Today, the LQ9 remains a popular choice for:

- Budget hot rod engine swaps

- Off-road vehicle builds

- Performance truck upgrades

- Race car applications requiring a strong foundation

Its combination of affordability, durability, and performance potential ensures the LQ9 will hold a place in automotive enthusiasts’ hearts for years to come.

The Bottom Line on the LQ9

The LQ9 engine represents a sweet spot in GM’s truck engine lineup—more powerful than standard options but without the price premium of newer LS3-based engines. Its iron block provides bulletproof reliability, while its aluminum heads help manage weight and heat.

If you’re looking for a solid foundation for a performance build or a reliable powerplant for an engine swap, the LQ9 deserves serious consideration. With proper maintenance and tuning, this 6.0L powerhouse can provide hundreds of thousands of miles of service while responding well to modifications.

Whether stock or modified, the LQ9 remains one of the most respected members of GM’s LS engine family—a true workhorse with the heart of a thoroughbred.