Looking to understand what makes the LM7 tick? Whether you’re planning an engine swap, rebuilding your truck’s powerplant, or just curious about this popular GM V8, you’ve come to the right place. This guide breaks down everything you need to know about the 5.3L Vortec that powered countless GM trucks and SUVs from 1999 to 2007.

What Is the LM7 Engine?

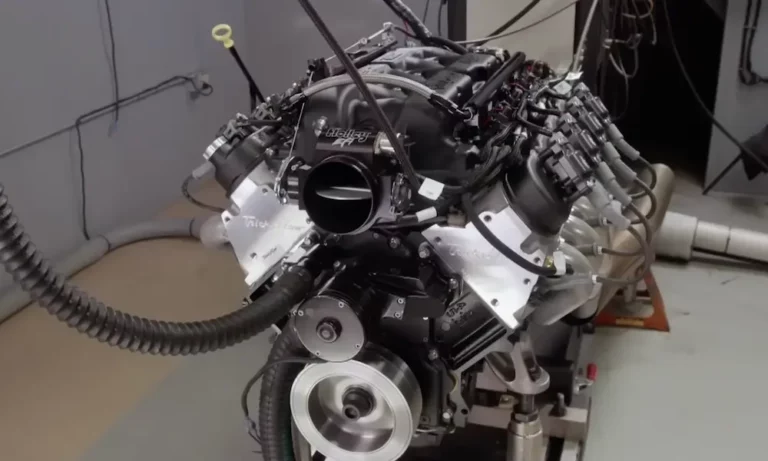

The LM7 is a 5.3-liter (325 cubic inch) V8 engine developed by General Motors as part of their Gen III small block family. This powerplant served as the backbone of GM’s truck lineup for nearly a decade, earning a reputation for reliability and solid performance.

Key features that define the LM7 include:

- Cast iron block with aluminum cylinder heads

- Part of the LS-based engine family

- Sequential multi-port fuel injection

- “Coil-Near-Plugs” ignition system

- 78.0 mm (3.07 inch) throttle body

While not the most powerful engine in GM’s lineup, the LM7 struck an excellent balance between everyday usability, decent power, and outstanding durability – making it a favorite among truck owners and engine swap enthusiasts alike.

LM7 Engine Specifications

Let’s dig into the technical details that make up the LM7’s DNA:

| Specification | Measurement |

|---|---|

| Displacement | 5.3L / 325 cubic inches (5327cc) |

| Bore | 96.0 mm (3.78 inches) |

| Stroke | 92.0 mm (3.62 inches) |

| Compression Ratio | 9.5:1 |

| Block Material | Cast iron |

| Head Material | Aluminum |

| Valvetrain | OHV, 2 valves per cylinder (16 total) |

| Firing Order | 1-8-7-2-6-5-4-3 |

The engine features a robust five-bearings crankshaft support system with:

- Crankshaft journal diameter: 65.0 mm (2.55 inches)

- Crankpin diameter: 53.3 mm (2.09 inches)

- Connecting rod length: 154.89 mm (6.098 inches)

These specifications created an engine that could handle daily driving while offering enough headroom for performance modifications down the road.

LM7 Power and Torque Figures

The LM7’s output increased over its production run as GM refined the engine. Here’s how the power figures evolved:

1999 Models

- 270 horsepower (201 kW)

- 315 lb-ft (427 N·m) of torque

2000-2003 Models

- 285 horsepower (213 kW)

- 325 lb-ft (441 N·m) of torque

2004-2007 Models

- 295 horsepower (220 kW)

- 335 lb-ft (454 N·m) of torque

These gradual improvements came through refinements in engine management and minor hardware updates, showing GM’s commitment to enhancing the platform throughout its lifecycle.

Camshaft Specifications

The stock LM7 camshaft specs played a crucial role in the engine’s character, offering a compromise between low-end torque and higher RPM power:

- Duration at .050 lift: 190/191 degrees (intake/exhaust)

- Lift: .466/.457 inches (intake/exhaust)

- Lobe Separation Angle (LSA): 114 degrees

- Timing: 112/116 (intake/exhaust)

This moderate cam profile contributed to the LM7’s excellent low-end torque while maintaining good drivability – exactly what you want in a truck engine.

Which Vehicles Used the LM7 Engine?

The LM7 powered a wide range of GM trucks and SUVs on the GMT800 platform from 1999 to 2007:

- Chevrolet Silverado 1500 (1999-2007)

- GMC Sierra 1500 (1999-2007)

- Chevrolet Suburban 1500 (2000-2006)

- GMC Yukon XL 1500 (2000-2006)

- Chevrolet Tahoe (2000-2006)

- GMC Yukon (2000-2006)

- Cadillac Escalade 2WD (2002-2005)

- Chevrolet Avalanche 1500 (2002-2006)

- Chevrolet Express 1500/2500 (2003-2007)

- GMC Savana 1500/2500 (2003-2007)

If you’re trying to identify a vehicle with an LM7, check the 8th digit of the VIN – the code “T” indicates an LM7 powerplant.

How to Identify an LM7 Engine

When examining an engine bay or looking at a potential engine for a swap, you can identify an LM7 through several key markers:

Block Casting Numbers

The most common LM7 block casting numbers include:

- 12567392

- 12567393

- 12551358

Physical Characteristics

- Deck height: 9.230-9.240 inches

- Bore spacing: 4.400 inches

- Thrust bearing location: #3 Main

Other Identifiers

- 24-tooth reluctor wheel

- Internally balanced crankshaft

- Cast iron block (unlike some other 5.3L variants with aluminum blocks)

These identifiers help distinguish the LM7 from other similar engines in the GM family, especially when sourcing parts or planning modifications.

LM7 Common Issues and Reliability

While generally considered reliable, the LM7 does have a few known issues to watch for:

Oil Consumption

Some LM7 engines develop oil consumption issues as they age, often related to:

- Worn valve seals

- Piston ring wear

- PCV system issues

AFM Problems (Later Models)

Some late-production LM7 engines received Active Fuel Management (cylinder deactivation), which can lead to:

- Lifter failures

- Excessive oil consumption

- Timing chain wear

Intake Manifold Gasket Failures

The factory intake manifold gaskets can deteriorate over time, causing:

- Coolant leaks

- Rough idle

- Poor performance

Despite these potential issues, properly maintained LM7 engines regularly exceed 200,000 miles without major problems – a testament to their robust design and construction.

Performance Potential and Upgrades

One reason for the LM7’s enduring popularity is its tremendous performance potential. The engine responds exceptionally well to modifications:

Bolt-On Performance Gains

Simple bolt-on modifications can yield significant power increases:

- Cold air intake: +10-15 hp

- Performance exhaust: +10-15 hp

- Tuning: +20-30 hp

Camshaft Upgrades

A popular first internal modification, aftermarket camshafts can transform the LM7’s personality:

- Mild truck cams: +30-40 hp with improved torque

- Performance cams: +50-70 hp with higher RPM potential

Forced Induction

The LM7’s iron block provides an excellent foundation for forced induction:

- Turbocharger systems: 500+ hp potential

- Supercharger kits: 450-600 hp depending on boost levels

Cylinder Head Improvements

Upgrading or porting the cylinder heads unlocks significant airflow improvements:

- Ported stock heads: +20-30 hp

- Aftermarket heads: +40-70 hp depending on design

With the right combination of modifications, an LM7 can easily produce 385+ horsepower and 390+ lb-ft of torque while maintaining reasonable reliability – numbers that aftermarket companies like ATK have demonstrated with their performance builds.

Engine Swap Compatibility

The LM7 has become a popular engine swap choice for several compelling reasons:

Popular Swap Applications

The LM7 fits well in numerous vehicles, including:

- Older GM trucks and SUVs

- Classic muscle cars (Camaro, Chevelle, etc.)

- S10/S15 pickups

- Fox-body Mustangs

- Jeep Wranglers

Swap Considerations

When planning an LM7 swap, keep in mind:

- Transmission compatibility (4L60E is most common)

- Engine management (standalone or modified factory)

- Oil pan clearance issues

- Accessory mounting

- Exhaust manifold/header clearance

The LM7’s widespread availability in junkyards and relatively low cost make it an attractive option for budget-conscious builders looking to inject modern LS performance into older vehicles.

The LM7 vs. Other GM Engines

How does the LM7 compare to its GM relatives? Let’s break it down:

LM7 vs. LS1

- Same 5.3L displacement vs. 5.7L in the LS1

- Cast iron block vs. aluminum in the LS1

- Lower power output (295 hp vs. 350 hp)

- More low-end torque

- Better durability under stress

LM7 vs. LQ4 (6.0L)

- Smaller displacement (5.3L vs. 6.0L)

- Similar cast iron block construction

- Lower power (295 hp vs. 300-345 hp)

- Better fuel economy

- More affordable and available

LM7 vs. LY5 (Successor)

- Same 5.3L displacement

- Similar power characteristics

- LY5 features Gen IV updates

- LY5 offers 315-320 hp and 335-340 lb-ft

- LM7 has simpler engine management

The LM7’s balance of availability, cost, durability, and performance potential often makes it the sweet spot for many builds, despite being outgunned in raw numbers by some of its GM siblings.

The LM7’s Legacy and Replacement

In 2007, General Motors phased out the LM7 in favor of updated designs:

LY5 Replacement

The direct replacement for the LM7 was the LY5, another 5.3L V8 that belonged to the Gen IV LS engine family. Key differences included:

- Power increase to 315-320 hp

- Torque increase to 335-340 lb-ft

- Variable valve timing

- Improved engine management systems

- VIN code “J” instead of “T”

LC9 Variant

Another notable successor was the LC9, which featured:

- Aluminum block (vs. iron in the LM7)

- Flex-fuel capability

- Primarily designed for 4WD applications

- Further refinements to power delivery

Despite being replaced, the LM7’s influence continues through its successors and the countless examples still powering vehicles today, not to mention its popularity in the engine swap community.

Performance Parts Availability

The aftermarket support for the LM7 remains robust, with countless companies offering performance parts:

Popular Aftermarket Components

- Cylinder heads: Summit Racing offers numerous options

- Complete engines: Companies like ATK sell upgraded LM7 packages with 500hp potential

- Camshafts: Countless profiles available from mild to wild

- Forced induction kits: Turbo and supercharger systems specifically designed for the 5.3L

- Intake manifolds: Options ranging from improved stock-style to high-rise performance designs

This extensive aftermarket support ensures that LM7 owners have plenty of options for building exactly the engine they want, whether it’s a mild street driver or an all-out performance monster.

Engine Building Tips for the LM7

If you’re planning to rebuild or modify an LM7, consider these expert recommendations:

Machine Work Recommendations

- Honing the cylinders with a torque plate for optimal ring seal

- Checking deck surface flatness (especially on higher-mileage blocks)

- Verifying main bearing alignment

- Inspecting for cracks around water jackets

Assembly Pointers

- Using ARP head studs for boosted applications

- Upgrading to multi-layer steel head gaskets

- Properly degreeing the camshaft

- Paying attention to piston-to-valve clearance with aftermarket cams

- Using thread sealant on block plugs to prevent leaks

Longevity Considerations

- Installing an improved oiling system for high-performance builds

- Using 4.8L pistons for increased compression in naturally aspirated builds

- Considering billet main caps for high-horsepower applications

- Installing a more efficient cooling system for demanding use

These tips come from expert advice accumulated through years of building and modifying these engines for maximum performance and reliability.

Tuning and Engine Management

Proper tuning is essential to unlocking the LM7’s potential:

Stock ECU Options

- HP Tuners and EFILive offer options to tune the factory computer

- Removing torque management for improved throttle response

- Adjusting fuel and spark tables for modified engines

- Disabling unnecessary emissions controls for off-road applications

Standalone Systems

For heavily modified engines or swaps, standalone engine management systems offer maximum flexibility:

- Holley Terminator X

- Fitech Ultimate LS

- MSD Atomic EFI

- AEM Infinity

The right tuning approach depends on your specific goals, modification level, and budget, but properly optimized engine management is the key to extracting maximum performance from an LM7.

Real-World LM7 Performance Examples

To illustrate the LM7’s potential, consider these real-world examples:

Street/Strip Build

- Mild cam upgrade (.575″ lift, 220° duration)

- CNC-ported heads

- Headers and 3″ exhaust

- Custom tune

- Results: 410hp, 420lb-ft, 12.2-second quarter mile

Truck Build

- 6-psi supercharger

- Stock bottom end

- Upgraded valvesprings

- 3″ exhaust

- Results: 480hp, 490lb-ft, daily driven with 18mpg highway

Budget Build

- Junkyard LM7 ($500)

- Truck intake manifold swap

- Headers

- Tune

- Results: 330hp, 350lb-ft for under $1,500 total

These examples demonstrate the versatility and potential of the LM7 platform across various budgets and performance goals.

The Future of the LM7

Despite being out of production for over 15 years, the LM7’s future remains bright:

- Continued popularity in engine swaps

- Steady supply of used engines in junkyards

- Robust aftermarket support

- Growing knowledge base and community

- Potential for integration with modern technologies

As modern engines become increasingly complex, the relative simplicity and proven performance of the LM7 will likely ensure its continued relevance for years to come.

The LM7’s combination of affordability, durability, and modification potential has secured its place as one of GM’s most impactful truck engines – a true workhorse that continues to prove its worth long after the end of its production run.