You’ve heard that small engines are reliable and efficient, but your Nissan’s 3-cylinder might be telling a different story. From mysterious knocking sounds to unexplained oil consumption, these compact engines pack plenty of problems alongside their power.

Let’s dive into what’s really happening with Nissan’s 3-cylinder engines, why these issues occur, and exactly what you can do about them.

The Evolution of Nissan’s 3-Cylinder Engines

Nissan’s journey with three-cylinder engines spans several generations, each with distinct characteristics and, unfortunately, recurring issues.

HR10 & HR10DDT (2019-Present)

The HR10 family represents Nissan’s modern small-displacement approach:

- 1.0L direct-injected turbo engine (999cc)

- Found in: Micra K14, Juke F16, and some Renault models

- 10.5:1 compression ratio

While relatively new to the market, early owner reports highlight start-stop system glitches and carbon buildup typical of direct injection engines.

HR12 Family (2011-2020)

This more established family includes several variations:

- HR12DE: Base naturally-aspirated version

- HR12DDR: Added supercharger with Miller-cycle valve timing

- HR12DDT (HRA2/HRA1): Powers 1.2 DIG-T Qashqai and Juke models

These engines have developed a concerning reputation. Poorly sized piston rings, thin oil control lands, and inadequate sump capacity have resulted in widespread oil consumption issues—sometimes as severe as 1 liter per 500 km.

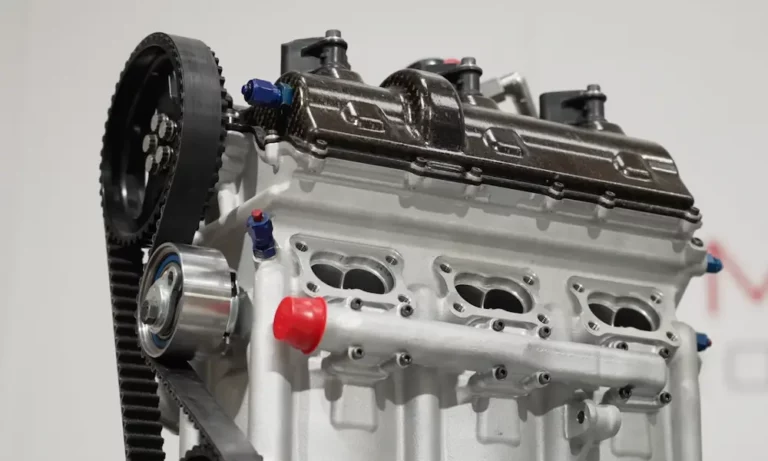

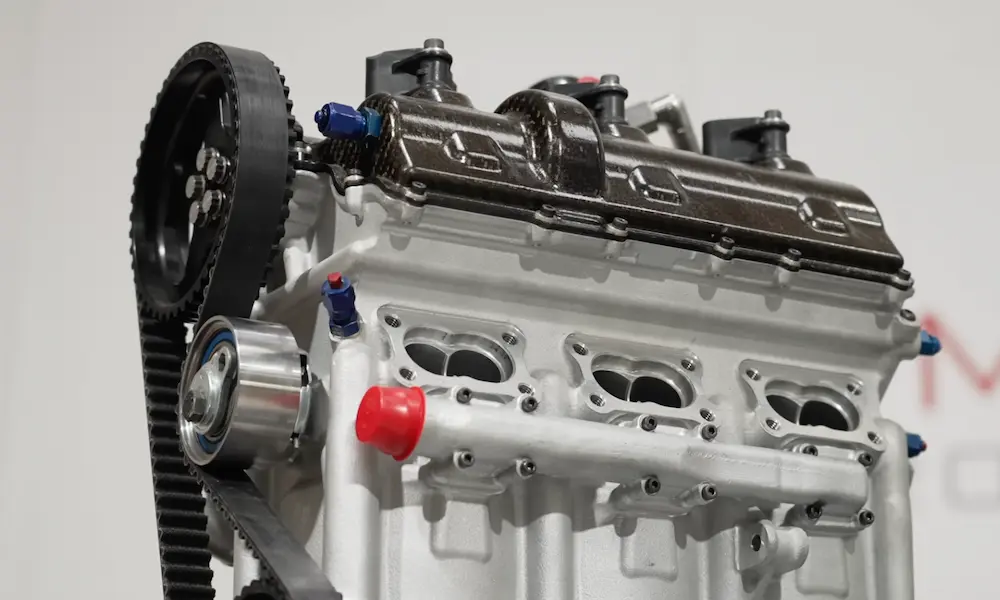

KR15DDT VC-Turbo (2021-Present)

Nissan’s flagship 3-cylinder offering uses complex variable compression technology:

- 1.5L displacement with multi-link mechanism

- Compression varies between 8:1 (power mode) and 14:1 (efficiency mode)

- Primarily used in 2021+ U.S. Rogue and other global models

This sophisticated engine combines high boost pressure (1.75 bar) with a complex crank-link system, creating a recipe for potential reliability issues.

Common Mechanical Problems in Nissan 3-Cylinder Engines

Timing Chain Stretch (HR12 & HR10)

Perhaps the most widespread issue plaguing Nissan’s 3-cylinder lineup is premature timing chain stretch.

The problem stem from:

- High chain operating speeds

- Modest oil pump capacity

- Extended oil drain intervals recommended by Nissan

Once the chain begins to stretch, you’ll notice:

- Distinctive rattle noise on cold starts

- Engine misfires and rough idle

- Check engine light with “crank/cam correlation” trouble codes (P0016/P0017)

A stretched timing chain isn’t just an annoyance—it can skip timing, causing severe engine damage. As one Qashqai owner on online forums noted: “The dealership quoted $1,200 for the timing chain replacement. It’s had the telltale rattle for months.”

Excessive Oil Consumption (1.2 DIG-T HR12DDT)

The 1.2 DIG-T engines suffer from a design flaw that causes alarming oil consumption rates. The culprits:

- Undersized oil scraper rings with insufficient radial tension

- High cylinder pressure (peaks of 200 bar)

- Inadequate PCV system design

This leads to:

- Oil consumption of 1 liter per 1,000-2,000 miles (sometimes worse)

- Low oil levels starving cam phasers and turbo bearings

- Eventual knock, detonation, and piston damage

The issue is so widespread that French consumers filed a class-action lawsuit alleging up to 400,000 engines produced between 2012-2016 show “excessive oil usage leading to seizure.”

Variable-Compression Bearing Failure (KR15DDT)

The sophisticated VC-Turbo represents Nissan’s technological flagship, but it’s also their most troubled 3-cylinder design.

In July 2025, NHTSA recall 25V437 covered nearly 444,000 vehicles because:

- Main, A-, C- and L-link bearings were machined with out-of-spec surface roughness

- Metal debris contaminated the lubrication system

- Sudden power loss occurred from bearing failure

According to NHTSA documentation, Nissan admits these defects may appear by just 20,000 miles. The company has since changed crank journal finishing processes and bearing alloy specifications.

Electronic and Sensor-Related Issues

Three-cylinder engines inherently produce more vibration than four-cylinder designs. This seemingly minor characteristic creates a cascade of secondary problems:

- Higher vibration amplitudes stress mounting brackets and wiring harnesses

- Indian Magnite/Kiger HR10 owners frequently report random ABS, EPS and radar-sensor warnings traced to loose ground straps and connector issues

- Early VC-Turbo Rogues experienced intermittent limp-mode caused by erroneous knock sensor readings

These electronic gremlins make diagnosis challenging, as symptoms often appear unrelated to the engine itself.

Regulatory Actions and Investigations

| Engine | Model Years | Status | Key Document |

|---|---|---|---|

| HR12DDT 1.2 DIG-T | 2013-2018 Qashqai, Juke | European collective lawsuit; no formal recall | French civil filing (June 2023) |

| HR12DDR 1.2 DIG-S | 2011-2014 Micra, Note | Service bulletin for timing chain kit & tensioner | Nissan NTB12-021b |

| KR15DDT VC-Turbo | 2021-2024 Rogue, etc. | U.S. recall 25V437; 1.2% defect rate | NHTSA Part 573 report |

The most significant regulatory action came in December 2023 when the Office of Defects Investigation opened preliminary evaluation PE23-023 after receiving reports of seized engines and metal debris in oil pans. Nissan’s subsequent recall commits dealers to bore-scope inspections and complete engine replacements when metal debris is detected.

Warning Signs: How to Identify Problems Early

Early detection can save you thousands in repair bills. Here’s how to identify each major issue before it becomes catastrophic:

| Symptom | Likely Root Cause | DIY Checks | Professional Remedy |

|---|---|---|---|

| Cold-start rattle lasting 1-2 seconds | HR12 chain elongation | Remove oil filler cap; check for slack on cam sprocket | Replace timing set (chain, guides, tensioner) |

| Check engine light + reduced power | KR15 bearing damage | Scan for P0101-P0300 codes, listen for rod knock | Dealer oil-pan inspection per recall |

| Oil lamp flickers during braking | DIG-T oil consumption | Check dipstick with every fuel fill | Updated ring pack installation; PCV improvements |

| Rough idle with fuel smell | VC-Turbo cylinder wash-down | Compression & leak-down testing | Warranty short-block replacement |

Real Owner Experiences

Across multiple platforms, owners report consistent patterns of problems:

- U.S. Rogue owners describe engine replacements as early as 15,000 miles, with dealers citing “bearing spall” as the cause. Most dealer repairs take 10-15 hours for a complete engine swap.

- Indian Magnite drivers note harsh CVT-downshift drone and rapid brake-pad wear. While not directly engine-related, these issues are exacerbated by the modest 999cc motor’s need to rev aggressively under load.

- UK Qashqai forums document stretched timing chains appearing at just 60,000 miles. Many owners abandon repair attempts because chain replacement labor costs exceed the vehicle’s remaining value.

One 2021 Rogue owner wrote on Reddit: “Dealer just replaced my entire engine at 32K miles. Started with a ticking sound that got louder over two weeks. Now I’m terrified it’ll happen again.”

Essential Preventive Actions for Current Owners

If you currently own a Nissan with a 3-cylinder engine, these proactive steps can help prevent catastrophic failure:

For All Nissan 3-Cylinder Engines

- Shorten oil change intervals to 5,000 miles/8,000 km (instead of Nissan’s recommended 10,000 miles)

- Use only high-quality synthetic oil meeting dexos1-Gen3/API SP specifications

- Consider an oil analysis with your next service to establish a baseline; elevated lead (Pb) or copper (Cu) indicates early bearing distress

- Listen carefully during cold starts for the telltale rattle of timing chain stretch

For VC-Turbo (KR15DDT) Owners

- Schedule the free NHTSA recall inspection as soon as possible

- Keep detailed maintenance records to protect your warranty coverage

- Pay attention to ANY new engine sounds – early intervention is critical

- Consider an extended warranty if you plan to keep the vehicle beyond the factory coverage

For HR12 DIG-T Owners

- Check oil level weekly until you understand your engine’s consumption rate

- Keep a quart of appropriate oil in the vehicle at all times

- Consider updated PCV components if available for your model

- Avoid extended high-speed driving if oil consumption is severe

Making Smart Buying Decisions

If you’re considering a used or new Nissan with a 3-cylinder engine:

Pre-Purchase Checks

- Cold start test: Listen for timing chain rattle in the first few seconds

- OBD scan: Look for stored misfire or correlation codes (even if the check engine light isn’t on)

- Compression test: Uneven readings could indicate ring or valve issues

- Oil level and condition: Low level or contaminated oil suggests poor maintenance

Model-Specific Advice

- VC-Turbo vehicles: Avoid early-build 2021 Rogues unless the recall has been completed with engine replacement. Choose late-2024 units built after August when bearing specifications were improved.

- HR12 DIG-T models: These can still be good buys if compression and oil usage are normal; insist on verifiable 5,000-mile oil change history.

- HR10 models: The newest in the lineup with fewer documented issues, but monitor them closely as they age.

Technical Maintenance Tips

For DIYers and professional technicians handling these engines:

- Always replace the variable timing control solenoid oil-screens during chain work; debris here often causes future phaser faults

- When installing a KR15 short-block, use Nissan’s special tool J-51199 to set proper control-shaft lash; improper preload causes actuator whine and trouble codes

- For HR12 engines, install the updated three-piece oil ring set and ECU flash if available for your model

- Carbon cleaning will be necessary for all direct-injection models around 60,000 miles; consider walnut blasting for the intake valves

The Future of Nissan’s 3-Cylinder Engines

Despite the troubling reliability record, Nissan continues to invest in 3-cylinder technology as emission regulations tighten globally. The company has:

- Updated manufacturing processes for the VC-Turbo bearings

- Developed hybrid applications using the 3-cylinder as a generator

- Invested in improved direct injection systems to reduce carbon buildup

Will these improvements be enough? While Nissan makes progress addressing known issues, the fundamental complexity of the VC-Turbo design and the high-stress nature of small-displacement turbocharged engines create inherent reliability challenges.

Conclusion

Nissan’s 3-cylinder engines represent ambitious engineering with real-world compromises. The conventional HR-series models suffer mostly from timing and lubrication issues that better maintenance can mitigate. However, the VC-Turbo introduced unprecedented mechanical complexity with its variable compression linkage, creating narrow tolerance margins that led to widespread bearing failures.

Despite these challenges, proper maintenance and early intervention can help owners extract the fuel-efficiency benefits these engines were designed to deliver. For those considering a 3-cylinder Nissan, weigh the documented risks against the potential rewards, and budget for diligent upkeep if you decide to take the plunge.