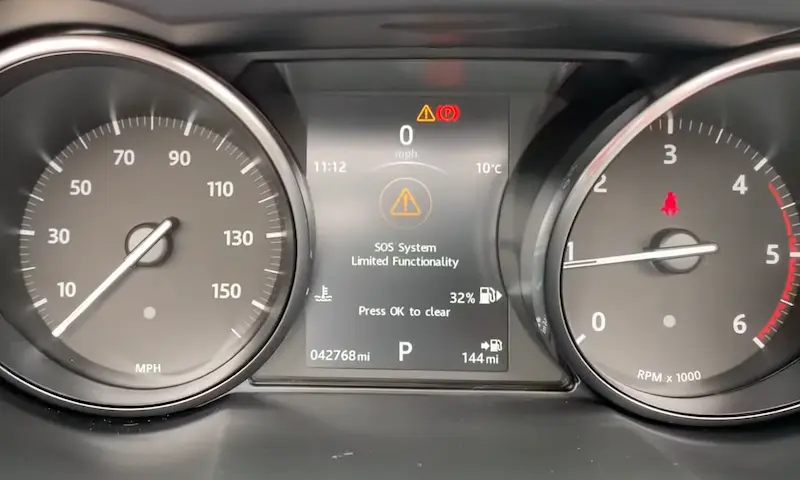

Seeing that dreaded “charging system fault” message on your Range Rover’s dashboard can instantly turn a good day bad. This warning often appears without warning and could mean anything from a simple fix to a complex electrical issue that might leave you stranded. Let’s dive into what causes these faults, how to identify them, and what you can do to get your luxury SUV back on the road.

What Causes Range Rover Charging System Faults?

When your Range Rover displays a charging system fault, it’s telling you there’s an issue with the components that generate, store, or distribute electrical power. Unlike simpler vehicles, Range Rovers use sophisticated Battery Management Systems (BMS) that monitor everything through advanced sensor networks.

Battery Management System Sensor Failures

The BMS sensor mounted on your battery’s negative terminal is often the culprit behind charging system warnings. This small but crucial component monitors:

- Current flow

- Voltage levels

- Battery temperature

When this sensor fails, your Range Rover can’t accurately assess the battery status or alternator output. What makes this particularly frustrating is that your charging system might be working perfectly fine, but the faulty sensor triggers warnings anyway.

Land Rover has acknowledged this issue and even released Technical Service Bulletin LTB00643 to address problems with the sensor’s fused harness connections.

Oil Leak Contamination of Alternators

One of the most expensive and common causes of Range Rover charging system faults is oil contamination. This typically happens when valve covers and timing covers leak oil that drips directly onto the alternator below.

This issue is particularly common in:

- 5.0L V8 models

- 4.4L V8 models

- 3.0L supercharged V6 engines

What makes this problem especially sneaky is that oil-contaminated alternators might test fine on a bench but fail intermittently when installed in the vehicle. The repair costs can be staggering—often exceeding $4,000 when both the oil leaks and alternator need addressing.

P0A1A Diagnostic Code Issues

If your mechanic finds a P0A1A code (indicating “Generator Control Module – Missing Message”), you’re dealing with a communication failure between your Engine Control Module and alternator control systems.

Range Rovers use computer-controlled alternators that receive charging commands through specialized communication protocols. When this communication breaks down, your alternator may:

- Stop charging completely

- Operate at incorrect output levels

- Trigger the charging system fault warning

Body Control Module and Gateway Module Failures

The Body Control Module (BCM) manages your charging system by integrating with various sensors and controllers. When it fails or experiences software corruption, it might misinterpret normal charging operation as faulty.

Gateway Module issues compound the problem by disrupting communication between different vehicle networks. This is particularly common in Discovery Sport and newer Range Rover models, often requiring specific reset procedures or module replacement.

How to Diagnose Range Rover Charging System Problems

Basic Voltage Testing

Before diving into complex diagnostics, start with these baseline measurements:

| Test Condition | Normal Reading | What It Means |

|---|---|---|

| Battery at rest | 12.4-12.6 volts | Healthy battery charge |

| Engine running (idle) | 14.0-14.5 volts | Alternator is charging |

| Engine at 2000 RPM with accessories on | 13.8-14.5 volts | System handles load properly |

Remember that Range Rovers use smart charging algorithms that adjust output based on conditions, so voltage may vary somewhat from these ranges.

More advanced testing should include checking for voltage drops between the alternator output and battery connections, which can identify high-resistance connections or damaged wiring.

Following Technical Service Bulletin Procedures

If your Range Rover matches the models covered by Land Rover’s TSB LTB00643 (including LR4, Range Rover Sport L320, and Range Rover L322), the fix might involve relocating and replacing the BMS sensor wiring harness.

This repair requires:

- Complete battery removal

- Careful wire routing modifications

- Specialized splicing techniques

While seemingly simple, this repair addresses a root cause of many intermittent charging system faults that persist despite replacing alternators and batteries.

BMS Reset Requirements

After any battery replacement or charging system repair, a proper BMS reset is mandatory. This isn’t something you can do without specialized equipment like the GAP IID Tool or similar professional scanners.

The reset process registers new battery parameters and allows the BMS to recalibrate. Skip this step, and you’ll likely experience:

- Disabled start/stop functions

- Reduced charging efficiency

- Continued fault warnings

Model-Specific Charging System Issues

Range Rover L322 (2003-2012)

The L322 generation, especially models with BMW-sourced 4.4L V8 engines, commonly experiences:

- Alternator bracket seal failures

- VANOS system oil leaks

- Valve cover gasket failures

These issues directly impact alternator performance through oil contamination. Repair costs typically range from $1,200-$2,500 depending on damage extent.

Range Rover Sport L320 and L494

The Range Rover Sport L320 (2006-2013) shares many vulnerabilities with the L322 but has additional issues due to its more compact engine bay. The tighter spacing between valve covers and alternators accelerates oil contamination problems.

The newer L494 generation (2014-2022) has improved alternator positioning but continues to experience oil leak-related failures. Typical repair costs range from:

- $800-$1,800 for alternator replacement alone

- $2,000-$4,500 when oil leak repairs are also needed

Discovery and LR3/LR4 Models

Discovery 3 (LR3) and Discovery 4 (LR4) models have unique charging system failure patterns due to their alternator mounting configurations. They frequently suffer from P0A1A codes related to alternator communication failures.

Discovery Sport models (2015-present) introduce different charging system architectures but continue experiencing BMS-related faults, particularly software issues requiring module reprogramming.

Repair Options and Costs

Alternator Replacement

Range Rover alternator replacement costs vary significantly based on model and engine type:

| Model Type | Parts Cost | Labor Cost | Total Range |

|---|---|---|---|

| 3.0L Turbo Engine | $414-$1,300 | $140-$980 | $1,373-$2,554 |

| Older Models | $400-$700 | $437-$232 | $837-$932 |

| With Oil Leak Repair | $1,200-$2,500 | $1,220-$2,269 | $2,420-$4,769 |

Critical to successful repair is addressing any underlying oil leaks. Installing a new alternator without fixing valve cover or timing cover leaks guarantees premature failure of your new part.

BMS Sensor and Wiring Harness Repairs

BMS sensor replacement typically costs:

- $75-$150 for the sensor itself

- $300-$600 total with labor

The key is determining whether the sensor failed on its own or if wiring harness degradation caused the problem. Repairs following TSB LTB00643 guidelines usually cost $400-$800 in labor plus parts.

BCM and Gateway Module Replacement

Body Control Module replacement is one of the most expensive charging system repairs:

- New BCM units: $800-$1,200 plus programming

- Used BCM modules: $75-$300 (but require VIN cloning services adding $200-$500)

Gateway Module issues often resolve through software updates or reset procedures costing $100-$300, making them more economical when applicable.

How to Prevent Charging System Problems

Regular Oil System Inspection

The best way to prevent oil-related alternator failures is through systematic inspection of:

- Valve cover gaskets

- Timing cover seals

- Vacuum pump assemblies

Early intervention with gasket replacement costs $400-$900, compared to $2,000-$4,500 for combined oil leak and alternator repairs after failure.

Pay special attention to vehicles exceeding 80,000 miles, where gasket degradation becomes common. Professional inspection every 30,000 miles enables early detection before problems affect charging components.

BMS System Care and Battery Maintenance

Protect BMS sensor connections from corrosion through:

- Regular terminal cleaning

- Dielectric grease application

- Inspection of BMS wiring harnesses

When replacing your battery, make sure to:

- Use OEM-equivalent batteries with appropriate specifications

- Perform proper BMS reset protocols (or have a professional do it)

- Check for corrosion or damage to battery terminals

A professional BMS reset following battery service costs $50-$150 but prevents more expensive diagnostic procedures when fault codes persist.

Advanced Diagnostic Considerations

Dealing with Intermittent Faults

Intermittent charging system faults are particularly challenging because they often appear only under specific conditions like:

- Wet weather

- Extreme temperatures

- Particular electrical load combinations

Diagnosing these requires professional scan tools capable of recording fault patterns during normal driving. The P0A1A code frequently appears intermittently due to marginal wiring connections that fail under certain conditions.

Software Updates

Modern Range Rover charging systems rely heavily on software that controls charging rates and coordinates communication between modules. Manufacturers periodically release updates that address known issues.

Professional diagnostic systems can identify available software updates that might solve persistent fault codes without expensive hardware replacement.

The Technology Behind Range Rover Charging Systems

What makes Range Rover charging systems so complex is their integration of multiple advanced components:

- Computer-controlled alternators that receive charging commands through specialized communication protocols

- Battery Management Systems that monitor micro-volt variations in system voltage

- Multiple control modules that must communicate perfectly for proper operation

This sophistication enables features like smart charging that adjusts output based on driving conditions, but creates additional failure points requiring specialized diagnostic equipment.

Taking Action When You See “Charging System Fault”

If your Range Rover displays a charging system fault:

- Check if your battery is older than 3-4 years (the most common simple fix)

- Look for signs of oil leakage around the alternator

- Have voltage readings taken at the battery (both engine off and running)

- Get a proper diagnostic scan with a professional-grade tool

- Address all underlying issues, not just the symptoms

Remember that Range Rover charging system faults require systematic diagnostic approaches beyond traditional alternator and battery testing. Success depends on understanding the relationships between mechanical components and electronic systems.

While DIY diagnosis is possible for the mechanically inclined, professional technicians with appropriate diagnostic tools and understanding of Land Rover technical service bulletins are best positioned to provide cost-effective solutions for these complex electrical issues.