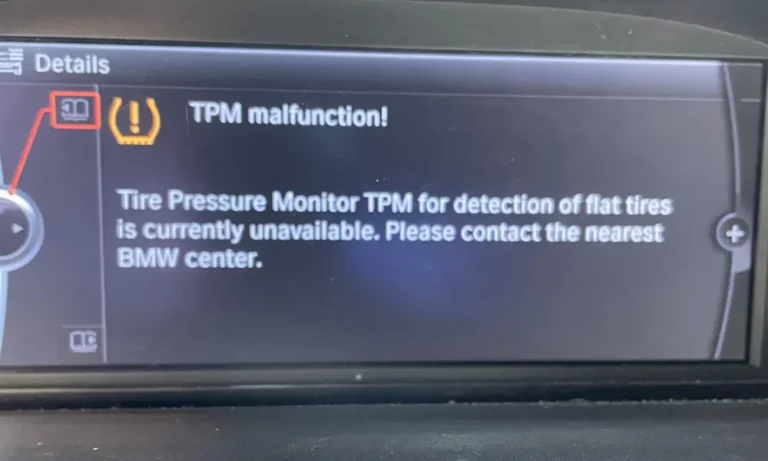

Having trouble with that annoying tire pressure warning light that won’t go away? BMW’s Tire Pressure Monitoring (TPM) system is notorious for throwing errors even when your tires look perfectly fine. If you’re seeing “TPM Malfunction” on your dashboard, you’re facing one of the most common issues BMW owners encounter. Let’s break down what’s happening, why it matters, and how to get it fixed without overpaying.

What Exactly is BMW’s TPM System?

BMW uses a direct tire pressure monitoring system that’s designed to keep you safe by alerting you to potentially dangerous tire pressure problems. Unlike some basic systems that just compare wheel rotation speeds, BMW’s system has actual pressure sensors inside each tire.

The system consists of four main components:

- Tire-mounted sensors that measure pressure and temperature

- An RDC module (Reifendruckkontrolle, German for “tire pressure control”)

- An antenna system that operates at 433MHz

- Dashboard integration that displays warnings when something’s wrong

Different BMW generations have different TPM setups. E-Series models (2007-2013) have separate RDC modules usually located in the trunk or wheel wells. F-Series (2011-2019) vehicles kept dedicated modules but moved them around depending on the model. The newest G-Series vehicles (2016+) integrated TPM functionality into the main stability control system.

How the System Actually Works

Those little sensors in your tires contain lithium batteries that typically last 5-10 years (though in reality, most fail around the 6-7 year mark). To save battery life, they don’t constantly transmit data—they only send signals when the car is moving, and they space out their transmissions.

When you’re driving, each sensor wirelessly communicates with the RDC module. This module processes the pressure data and sends it through your car’s computer network to display on your dashboard. When any part of this chain breaks down—whether it’s a dead sensor battery or a failed module—you get the dreaded “TPM Malfunction” message.

Why Your TPM System is Malfunctioning

The Most Common Failures

Dead sensor batteries are by far the most frequent culprit. After about 5-7 years, the batteries start to weaken, causing spotty communication before they die completely. Unlike some car systems that give you a gradual heads-up, BMW’s sensors tend to work fine one day and fail the next with little warning.

RDC module problems are the next most common issue. These modules often live in vulnerable areas where they’re exposed to water and corrosion. When moisture gets in, the internal circuits get damaged, and the whole system shuts down. You’ll usually see all four tire positions showing as unreadable when this happens.

Antenna system issues can also cause intermittent problems. The antennas that pick up sensor signals can corrode or get physically damaged, leading to communication problems that come and go seemingly at random.

Diagnostic Codes That Tell the Story

When scanned with a proper diagnostic tool, your BMW will report specific fault codes that help pinpoint what’s wrong:

- Code 604E: General RDC system errors (often points to the module itself)

- Code 6059: “Wheel electronics undefined” (usually means sensor issues)

- Codes 6054-6057: Individual wheel sensor failures (each code corresponds to a specific wheel)

- Code 6053: Antenna reception problems

How to Diagnose Your TPM Problem

Start With the Basics

Before diving into complex diagnostics, try these simple steps:

- Check all your tire pressures with a good gauge. Sometimes the actual problem is just low pressure, and the system is working correctly!

- Try a system reset through your iDrive interface:

- Navigate to Vehicle > Vehicle Status > Tire Settings

- Select “Perform Reset”

- Drive for 10-15 minutes at over 25 mph

If the system resets successfully, great! If it gets stuck at 49% or immediately shows errors again, you likely have a hardware problem.

Getting Into Deeper Testing

To properly test your TPMS sensors, you’ll need specialized equipment like an Autel MaxiTPMS scanner or similar tool. These devices can “wake up” individual sensors to check their battery voltage and signal strength. Any sensor reading below about 2.8 volts probably needs replacement.

Testing the RDC module is more complex and involves checking power, ground, and communication signals. Most DIY mechanics skip straight to module replacement if they’ve eliminated sensors as the problem.

Finding Your RDC Module

Depending on your BMW model, the RDC module location varies:

- E90/E92/E93 3-Series: Behind the rear passenger seat or in the trunk near the battery

- X3 F25 models: In the right rear wheel well area, accessible from underneath

- 1-Series and 2-Series: Often in the trunk behind side panels

- G-Series models: No separate module (integrated into the DSC system under the rear seat)

Fixing Your TPM Problems

Replacing Sensors

Individual sensor replacement typically costs $50-100 per sensor plus installation labor. You can use genuine BMW sensors or quality aftermarket alternatives that cost a bit less. Since the tires need to be dismounted to replace sensors, it makes sense to do this during regular tire replacement if possible.

Most BMW models don’t require special programming for new sensors—the system automatically recognizes properly functioning 433MHz sensors after you perform the reset procedure. Just make sure you’re getting the correct frequency for your vehicle.

Replacing the RDC Module

If you need a new RDC module, expect to pay $300-600 including labor. The replacement process involves:

- Locating the module in your specific BMW model

- Disconnecting the power and removing access panels

- Unplugging electrical connections and removing mounting hardware

- Installing the new module

- Programming the module to match your vehicle

The programming requirements vary by generation. E-Series vehicles often need NCS Expert software, F-Series models require E-Sys tools, and G-Series typically need dealer-level programming due to the integrated nature of the system.

Resetting the System After Repairs

After replacing components, you’ll need to reset the system:

- Check that all tires have the correct pressure

- Go to Vehicle > Vehicle Status > Tire Settings in your iDrive menu

- Select “Perform Reset”

- Start the engine but wait a moment before driving

- Drive continuously for 10-15 minutes at speeds over 25 mph

- Monitor the reset progress—success shows as “TPM Active”

What You’ll Pay: Cost Breakdown

| Component | Cost Range | Labor Hours | Total Cost |

|---|---|---|---|

| Single TPMS Sensor | $50-$100 | 0.5-1.0 | $80-$150 |

| Set of 4 Sensors | $200-$400 | 1.0-2.0 | $300-$600 |

| RDC Module | $200-$400 | 1.0-2.0 | $350-$650 |

| RDC Antenna | $100-$150 | 0.5-1.0 | $150-$250 |

| Programming/Coding | $100-$200 | 1.0-1.5 | $100-$300 |

Making Smart Repair Decisions

If diagnostic codes point to a single failed sensor, replacing just that one makes economic sense—especially if the others are still relatively new. However, if multiple sensors are failing or all your sensors are 7+ years old, replacing the complete set is more cost-effective than making multiple trips to the shop.

When the RDC module has failed, you’ll need to replace it regardless of sensor condition. But if your sensors are also aging, consider replacing them at the same time to avoid future headaches.

DIY vs. Professional Repair

What You Can Handle Yourself

If you’re mechanically inclined, you can tackle some parts of TPM repair:

- Sensor replacement during tire service is quite accessible. Most tire shops will install customer-supplied sensors when mounting tires, saving you on parts markup.

- System reset procedures require no special tools—just follow the menu steps in your iDrive system.

Replacing the RDC module varies in difficulty depending on your model. Some locations like the X3 F25 wheel wells offer easy access, while others require removing interior trim panels.

When to Bring in the Pros

You’ll probably need professional help for:

- Programming and coding the system after module replacement, which typically requires dealer-level equipment or specialized software like NCS Expert or E-Sys.

- Complex diagnostics when you have multiple fault codes or intermittent problems that are hard to pin down.

Preventing Future Problems

Stay Ahead of Failures

- Check pressures regularly with a quality gauge. Monthly verification helps identify real pressure problems before they trigger system warnings.

- Monitor sensor batteries by getting them scanned during regular service intervals. This lets you plan replacements before emergency failures.

Smart Service Planning

- Coordinate with tire service by planning sensor replacement during tire changes or rotations to minimize labor costs.

- Winter preparation should include TPM reset procedures when switching to winter wheels. Some BMW models can even be coded to disable TPM warnings when using non-TPM equipped winter wheels.

The Bottom Line on BMW TPM Malfunctions

BMW’s TPM system is reliable when working properly, but component failures are common after 5-7 years. Sensor battery failure is the most frequent issue, with replacement running $50-100 per sensor. Complete RDC module failure causes system shutdown and typically costs $300-600 to repair, including programming.

Early intervention through regular monitoring can prevent more extensive system failures. While DIY approaches work well for basic sensor replacement, professional diagnosis becomes valuable for complex issues involving multiple components.

Understanding your specific BMW’s TPM system architecture and knowing the component locations gives you a big advantage when talking to mechanics or attempting repairs yourself. With the right approach, you can keep your TPM system working properly without breaking the bank.