Ever noticed your Range Rover sitting awkwardly low on one side? Or heard that dreaded hissing sound from underneath? You’re facing one of the most common and expensive issues with these luxury SUVs: a suspension fault. While Range Rovers deliver exceptional comfort and capability, their sophisticated air suspension systems can turn into a financial nightmare when they fail.

What Causes Range Rover Suspension Faults?

Range Rover’s air suspension system is a complex network of components working together to provide that magic carpet ride. When it works, it’s brilliant. When it fails, it’s expensive.

The Air Suspension Components Most Likely to Fail

The system consists of several key parts, each prone to specific issues:

- Air Springs (Air Bags): These rubber components replace traditional coil springs and are the most common failure point. They deteriorate from constant pressure changes, road debris, heat, and moisture. When they crack or develop punctures, air leaks out and forces other components to work harder.

- Air Compressor: This workhorse generates pressurized air for the entire system. When air springs leak, the compressor works overtime trying to maintain pressure. Original equipment compressors, especially Hitachi units in L322 models, typically fail after 100,000-150,000 miles.

- Valve Block: This component controls air distribution throughout the system. When it fails, compressed air can’t reach the air springs properly. Valve blocks are particularly expensive, often costing $800-1800 at dealerships.

- Height Sensors: These monitor the vehicle’s position and tell the system when adjustments are needed. They can become damaged or misaligned, sending incorrect signals to the control unit.

- Electronic Control Unit: The computer brain managing the whole system. Software glitches or electrical problems here can cause system-wide failures.

How Your Driving Habits Affect Suspension Life

Your driving patterns significantly impact how long your Range Rover’s suspension will last:

- Off-road driving exposes components to debris, impacts, and extreme positions that accelerate wear

- Cold weather operation can cause pressure relief valves to freeze open, resulting in air pressure loss

- Extended periods of parking without use can lead to air leaks and compressor issues

- Overloading the vehicle puts additional strain on air springs and compressors

How to Identify a Range Rover Suspension Fault

Catching suspension problems early can save you thousands. Here are the telltale signs to watch for:

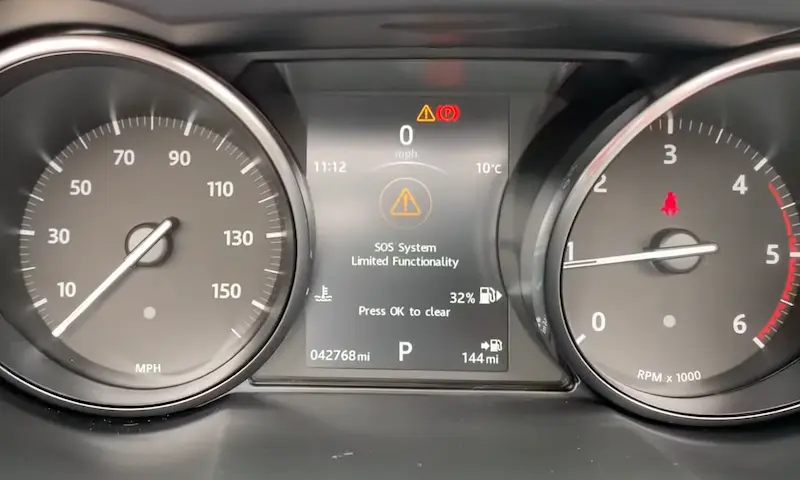

Warning Lights and Error Codes

The most obvious indicator is the suspension warning light on your dashboard. When this illuminates, the vehicle has detected a fault in the system. Common error codes include:

- C1A20-64: Indicates “pressure increases too slow when filling reservoir” – typically points to a weak or failing compressor

- C1A13-64: Signals “pressure does not decrease when venting gallery” – indicating problems with the exhaust valve system

- C1A36-01: Points to “exhaust valve general failure”

- U0421-68: Indicates “invalid data received from ride level control module”

Physical Signs Your Suspension Is Failing

Beyond warning lights, look for these visual and physical indicators:

- Uneven ride height: One corner or side sitting lower than others

- Sagging overnight: Vehicle noticeably lower in the morning than when parked

- Compressor running continuously: Listen for the air compressor running for extended periods

- Hissing sounds: Audible air leaks around the vehicle

- Rough or bouncy ride: Loss of the typical smooth Range Rover ride quality

- “Bottoming out”: Suspension hits bump stops over normal road imperfections

The Bounce Test: A Simple DIY Check

Here’s a quick test you can perform yourself:

- Push down firmly on each corner of the vehicle

- Release and observe how it rebounds

- Healthy suspension will bounce once and return to position

- Faulty suspension will either bounce multiple times or fail to return to normal height

Which Range Rover Years Have the Worst Suspension Problems?

Not all Range Rovers are created equal when it comes to suspension reliability. Some model years are notorious for issues.

The Most Problematic Range Rover Models

The 2006-2013 period represents the worst years for suspension reliability, including:

- L322 generation (2002-2012): Particularly the 2008-2012 model years show high failure rates once vehicles reach 100,000 miles.

- L320 Range Rover Sport (2006-2013): The first-generation Sport has the most documented suspension problems. First-year models (2006) are especially susceptible to premature failures.

| Model | Years to Avoid | Common Issues |

|---|---|---|

| Range Rover (Full Size) | 2008-2012 | Air spring deterioration, compressor failures, valve block issues |

| Range Rover Sport | 2006-2009 | Air spring leaks, compressor failures, height sensor malfunctions |

Recent Improvements in Range Rover Suspension

Newer generations show significant improvement:

- L405 Range Rover (2013-2022): Much better suspension reliability

- L494 Range Rover Sport (2014-2023): Fewer reported issues, though problems can still occur

Recent Recall Information

In August 2025, Jaguar Land Rover recalled 121,509 Range Rover and Range Rover Sport vehicles from 2014-2017 model years due to cracked front suspension knuckles. The aluminum front suspension knuckle can develop cracks where it connects to the upper control arm ball joint, potentially causing steering loss.

Range Rover Suspension Repair Costs: What to Expect

Prepare yourself for sticker shock. Range Rover suspension repairs rank among the most expensive in the automotive world.

Dealer vs. Independent Shop Pricing

The price difference between dealership and independent shop repairs is substantial:

| Repair Type | Dealer Cost | Independent Shop | Savings |

|---|---|---|---|

| Complete System Replacement | $5,000-8,000 | $3,000-5,000 | ~40% |

| Single Air Spring | $800-1,500 | $400-800 | ~50% |

| Air Compressor | $1,200-2,500 | $800-1,500 | ~40% |

| Valve Block | $800-1,800 | $500-1,000 | ~45% |

Aftermarket Solutions That Can Save You Money

Several companies offer quality alternatives to expensive OEM parts:

- Arnott: Offers rebuilt air springs and compressors at 50-70% of OEM prices

- Strutmasters: Provides both replacement air components and conversion kits

- Aftermarket parts: A complete set of four aftermarket air springs costs $800-1,600 versus $3,200-5,000 for OEM parts

Air-to-Coil Conversion: A Permanent Solution?

For many owners facing expensive air suspension repairs, converting to traditional coil springs offers a permanent solution:

- Cost: Complete conversion kits range from $500-1,200

- Benefits: Eliminates expensive air suspension repairs, improves reliability in extreme weather, reduces complexity

- Drawbacks: Loses adjustable ride height capability, may impact resale value, requires electronic bypass modules to prevent warning lights

Companies like Suncore, Strutmasters, and Terrafirma offer comprehensive conversion kits that replace the entire air suspension system with traditional coil springs and shock absorbers.

DIY Suspension Diagnosis and Repair

Before spending thousands at a dealer, consider diagnosing the problem yourself.

Tools You’ll Need for Basic Diagnosis

- OBD-II scanner with Land Rover capability (GAP IID or similar)

- Pressure gauge to test compressor output

- Soapy water spray to locate air leaks

- Multimeter for testing electrical components

- Torque wrench for proper installation

Step-by-Step Diagnosis Process

- Read fault codes: Connect a scanner to retrieve specific error codes

- Visual inspection: Look for obvious damage to air springs, lines, or connections

- Listen for leaks: With the engine running, listen for hissing sounds around each wheel

- Pressure test: Check gallery pressure (should reach approximately 16 bars/232 PSI)

- Monitor compressor: Watch for extended runtime or overheating (above 138°C/280°F)

Replacing Air Springs: A Manageable DIY Project

If you’re mechanically inclined, replacing air springs is within reach of DIY enthusiasts:

- Access the suspension component (usually requires removing wheel and surrounding parts)

- Depressurize the system using a diagnostic tool

- Disconnect electrical connections and air lines

- Remove mounting bolts and brackets

- Install new component in reverse order

- Initialize system using proper procedure

Preventive Maintenance to Avoid Suspension Failures

An ounce of prevention is worth a pound of cure – especially with Range Rover suspensions.

Regular Inspection Routine

Implement these simple checks to catch problems early:

- Monthly visual inspection of air springs for cracks or bulges

- Check for unusual vehicle positioning, particularly after overnight parking

- Listen for unusual compressor noise or continuous operation

- Test suspension height adjustment functionality regularly

Compressor Maintenance Tips

Keep your compressor healthy with these steps:

- Inspect the desiccant filter regularly – it removes moisture from the system

- Clean the brass filter on the air compressor to prevent blockages

- Ensure proper battery voltage – low voltage triggers excessive compressor cycling

- Park in climate-controlled spaces when possible to reduce environmental stress

Protecting Your Suspension in Extreme Weather

Cold weather is particularly hard on air suspension systems:

- Keep battery fully charged in winter months

- Allow vehicle to warm up before driving in extreme cold

- Consider a block heater in sub-zero climates

- Use parking height adjustment to reduce stress when parked for extended periods

Understanding Your Warranty Coverage

Know what protection you have before problems arise.

Factory Warranty Coverage for Suspension

Range Rover’s standard warranty typically covers:

- 4 years or 50,000 miles for most suspension components

- Air suspension components under the vehicle’s mechanical warranty

- Wear items may have limited coverage or exclusions

Extended Warranty Options

Consider these extended protection plans:

- Land Rover Vehicle Service Protection offers coverage up to 7 years/120,000 miles

- Third-party warranties may provide more affordable options but check for air suspension exclusions

- Certified Pre-Owned vehicles include extended warranty coverage

What Voids Your Suspension Warranty

Be careful about these warranty-voiding actions:

- DIY repairs or modifications to the suspension system

- Using non-approved parts or accessories

- Failure to address recall notices

- Missing scheduled maintenance

- Off-road damage considered “abuse”

Is a Range Rover with Suspension Problems Worth Buying?

If you’re considering a used Range Rover with known suspension issues, here’s what to weigh:

Evaluating a Potential Purchase

- Get a professional pre-purchase inspection specifically checking suspension components

- Budget $2,000-5,000 for potential suspension repairs when buying a 2006-2013 model

- Verify completion of the 2025 suspension recall on 2014-2017 models

- Consider newer L405 (2013+) and L494 (2014+) models for better reliability

Negotiating Price Based on Suspension Condition

Use these factors to adjust your offer:

- Complete suspension replacement costs $5,000-8,000 at dealerships

- Partial failures (one corner or compressor only) still run $1,000-2,500

- Factor in 100% of repair costs for immediate issues

- For older vehicles, assume 50% of replacement cost as inevitable within 2-3 years

The Long-Term Ownership Equation

Consider these long-term factors:

- Air suspension problems tend to cascade – one failure often leads to others

- Budget for ongoing maintenance costs of $800-1,500 annually for aging systems

- Coil conversion provides reliability but affects resale value and capability

- Weigh luxury and capability benefits against higher maintenance costs

The Future of Range Rover Suspension Technology

Land Rover continues to evolve their suspension systems in newer models.

Improvements in Recent Models

Newer Range Rovers incorporate several improvements:

- More durable air spring materials resistant to environmental damage

- Enhanced compressor design with improved cooling and filtration

- Better diagnostic capabilities for early problem detection

- More resilient valve blocks with improved sealing

Alternative Suspension Options in Newer Range Rovers

Recent models offer more suspension choices:

- Standard coil suspension on base models of newer Range Rover Sport

- Electronic adaptive damping without air springs on some configurations

- Plug-in hybrid models with modified suspension tuning for battery weight

What to Expect in the Next Generation

Looking ahead to future models:

- Increased integration with active anti-roll systems

- Predictive suspension adjustment using navigation data

- More serviceable components designed for easier replacement

- Expanded self-diagnosis and early warning capabilities

Range Rover suspension faults represent one of the most significant ownership challenges for these premium SUVs. By understanding the common problems, recognizing early warning signs, and knowing your repair options, you can make informed decisions that save thousands while maintaining your vehicle’s legendary capability and comfort.