Choosing the right battery isn’t just about grabbing the cheapest option off the shelf. Whether you’re dealing with a modern car, RV, or solar setup, understanding the difference between AGM and lead-acid batteries can save you money and headaches down the road. Let’s break down what sets these two apart and help you figure out which one fits your needs.

What Makes These Batteries Different?

How Traditional Lead-Acid Batteries Work

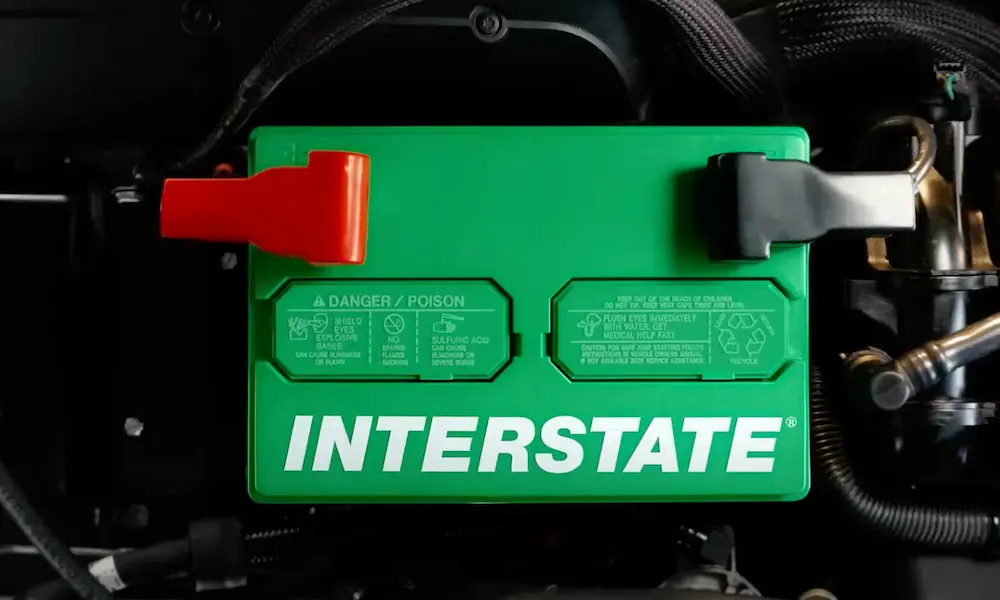

Traditional flooded lead-acid batteries haven’t changed much since the 1880s. They’re built with flat lead plates sitting in a pool of liquid electrolyte—basically sulfuric acid mixed with distilled water. The positive plates use lead dioxide while the negative plates are spongy lead.

The electrolyte sloshes around freely, which means you’ve got to keep these batteries upright or you’ll have a mess on your hands. You’ll also need to top them off with distilled water regularly since the liquid evaporates during charging. It’s old-school tech, but it’s proven and affordable.

The AGM Battery Innovation

AGM batteries flip the script entirely. Developed for military aircraft in the 1980s, they use thin fiberglass mats that absorb and hold the electrolyte between the lead plates. No free-flowing liquid means no spills, no matter how you mount them.

These fiberglass mats do double duty. They keep the electrolyte in contact with the plates while creating channels for oxygen recombination—a fancy way of saying the battery recycles its own gases back into water. This makes them completely sealed and maintenance-free.

Performance: Where AGM Batteries Pull Ahead

Power Delivery and Charging Speed

Here’s where things get interesting. AGM batteries have internal resistance as low as 2%, compared to 10-15% for flooded batteries. What does that mean for you? Faster charging and more consistent power output.

AGM batteries can accept charge currents up to 30% of their capacity, while flooded batteries max out around 10%. If you’re using solar panels or need quick recharges, that’s a game-changer.

The charging voltage differs too. AGM batteries need 14.4-14.8V for cycle charging and 13.5-13.8V for float charging. Traditional lead-acid batteries work with 13.8-14.4V. It’s not a huge difference, but using the wrong charger can damage your battery.

How Deep Can You Discharge?

This is crucial. AGM batteries handle 80% depth of discharge without breaking a sweat. Flooded batteries? You shouldn’t push them past 50% if you want them to last.

Let’s make this practical: A 100Ah AGM battery gives you 80Ah of usable power. A 100Ah flooded battery only delivers 50Ah safely. That’s a massive difference when you’re planning a battery bank for your RV or off-grid cabin.

Cycle Life Comparison

| Battery Type | Cycles at 50% DOD | Cycles at 80% DOD |

|---|---|---|

| AGM | 500-1,000 | 300-500 |

| Flooded Lead-Acid | 200-500 | Rapid degradation |

At 50% depth of discharge, AGM batteries deliver 500-1,000 cycles, while flooded batteries give you 200-500. Push an AGM to 80% and you’ll still get 300-500 cycles. Try that with a flooded battery and you’re asking for trouble.

How Long Will They Last?

Expected Service Life

AGM batteries typically run 4-7 years in cycling applications. If you’re using them for standby power, they can hit 6-10 years. Traditional flooded batteries generally last 2-5 years, depending on how well you maintain them.

Several factors explain this difference. AGM batteries resist sulfation better, which means they handle sitting unused without losing capacity. The sealed construction prevents electrolyte stratification—when acid concentration gets uneven throughout the battery. Flooded batteries suffer from this constantly.

Vibration destroys flooded batteries over time. The liquid electrolyte lets the active material shake loose from the plates. AGM’s glass mat structure holds everything tight, making them way more durable in rough conditions.

Temperature Tolerance

AGM batteries operate from -40°C to 60°C (-40°F to 140°F). Flooded batteries work in the narrower range of -20°C to 50°C (-4°F to 122°F). That matters if you’re in extreme climates.

At -20°C, AGM batteries retain about 50% of their rated capacity. Flooded batteries perform worse. And here’s a bonus: AGM batteries can’t freeze and crack like flooded batteries because the electrolyte doesn’t expand the same way.

The Money Question: What’s It Really Going to Cost?

Upfront Investment

Let’s not sugarcoat it—AGM batteries cost 40-100% more upfront. A typical 12V 100Ah flooded battery runs $50-$150. The same capacity in AGM will set you back $150-$500.

That sticker shock stops a lot of people. But focusing only on initial cost misses the bigger picture.

Total Cost Over Time

Here’s where the math gets interesting. Remember that usable capacity difference? If you need 100Ah of actual usable power, you’ll need two 100Ah flooded batteries (200Ah total at 50% DOD). But you’d only need one 125Ah AGM battery (125Ah total at 80% DOD).

Over ten years, those flooded batteries might need replacing 2-3 times, plus you’re spending $20-$50 annually on maintenance. The AGM system needs one replacement and zero maintenance.

When you run the numbers that way, AGM often comes out cheaper in the long run.

Maintenance: The Hidden Time Sink

What Flooded Batteries Demand

Traditional flooded batteries are needy. You’ll need to check water levels monthly and add distilled water when they run low. You’ll also need a hydrometer to check the specific gravity of the electrolyte and make sure your battery’s healthy.

Equalization charging prevents electrolyte stratification—basically controlled overcharging that mixes everything up and balances the cells. Terminal cleaning fights corrosion buildup. And you need proper ventilation because these batteries produce hydrogen gas during charging.

If you don’t do this stuff regularly, your battery dies early. If maintenance access is difficult—like in a marine application or tucked under an RV—flooded batteries become a real pain.

AGM’s Set-It-and-Forget-It Approach

AGM batteries eliminate all that hassle. The oxygen recombination process converts gases back to water internally, so you never add water. The sealed construction prevents the corrosive spills that plague flooded battery terminals.

There’s one catch: you need the right charger. Standard automotive charging systems can overcharge AGM batteries, potentially causing thermal runaway. Smart chargers with AGM-specific profiles are essential.

Safety Matters More Than You Think

AGM Safety Advantages

AGM batteries won’t spill even if you crack the case. That makes them safe for transportation and installation in tight spaces. During charging, they produce minimal gassing compared to flooded batteries, which pump out hydrogen and oxygen that can explode without proper ventilation.

The internal recombination process eliminates those dangerous emissions. You can safely install AGM batteries indoors, in boats, or anywhere ventilation is limited.

Environmental Considerations

Both battery types are about 99% recyclable through established networks. Lead, plastic, and sulfuric acid components all get recovered and reused. That’s genuinely impressive.

The longer lifespan of AGM batteries provides environmental benefits by reducing replacement frequency and manufacturing impacts. The sealed design also prevents electrolyte contamination that can happen when damaged flooded batteries leak into soil and groundwater.

Battery manufacturing produces 150-200 kg of CO2 per kWh of capacity. AGM batteries spread that environmental cost over more years of service.

Start-Stop Vehicles Need AGM Batteries

Why Start-Stop Systems Are Different

Modern vehicles with start-stop technology automatically shut down the engine at stoplights and restart when you release the brake. Great for fuel economy, brutal on batteries.

A typical commute might involve 12-20 start cycles versus a single start for conventional vehicles. Plus, regenerative braking systems recover energy during deceleration, requiring batteries that accept rapid charging without damage.

Traditional flooded batteries weren’t designed for this. They were built for one start per trip, not constant cycling.

Why AGM Wins for Start-Stop

AGM batteries can handle 60,000 engine starts compared to 20,000 for flooded batteries. That low internal resistance accepts rapid charging during regenerative braking, and the superior cycling capability handles the constant charge-discharge cycles.

The sealed construction prevents electrolyte stratification during frequent partial charges. AGM batteries also maintain stable voltage when your engine’s off but the AC, radio, and navigation are running.

If your vehicle has start-stop technology, AGM isn’t optional—it’s required for proper operation and longevity.

Special Applications Where AGM Shines

Marine and RV Use

Boats and RVs put batteries through hell. Constant vibration damages flooded battery plates and causes spills. AGM batteries resist these stresses through their immobilized electrolyte and reinforced structure.

You can mount AGM batteries in any orientation except completely inverted. That flexibility matters when you’re working with limited space. The deep cycling requirements for house power systems align perfectly with AGM’s 80% discharge capability.

Off-Grid and Solar Storage

Solar setups demand batteries that handle daily deep cycling, extended storage periods, and temperature extremes. AGM batteries check all these boxes with superior cycle life and low self-discharge rates of 1-3% per month versus 5-15% for flooded batteries.

That low internal resistance shines during peak solar production when you need rapid charging. The sealed construction keeps out dust and moisture that plague flooded batteries in outdoor installations.

The Limitations You Should Know

Where AGM Falls Short

AGM batteries aren’t perfect. That 40-100% higher initial cost is real money. Sensitivity to overcharging is a genuine concern—voltage exceeding 15V can cause thermal runaway and permanent damage.

Energy density limitations mean AGM batteries provide less power per pound than some other technologies, making them less suitable for weight-critical applications. Once an AGM battery dies, you can’t restore capacity by replacing electrolyte like you can with flooded batteries.

When Flooded Batteries Make Sense

Traditional flooded batteries still have their place. The lower cost matters when you’re on a tight budget and can perform maintenance. The ability to service cells by adding water and electrolyte can extend life in well-maintained installations.

Flooded batteries handle brief, intense current draws more effectively than AGM. The open cell design allows individual cell monitoring and service, potentially extending system life through selective cell replacement.

Making Your Decision

The choice between AGM and lead-acid comes down to your specific situation. AGM batteries excel when you need deep cycling, vibration resistance, maintenance-free operation, and extended lifespan. They’re ideal for start-stop vehicles, marine use, off-grid systems, and premium automotive applications.

Traditional flooded batteries remain the cost-effective solution for basic starting applications where you can perform maintenance and don’t need deep cycling. Their proven technology, wide availability, and serviceability work great for conventional automotive use and backup power systems where initial cost is the primary concern.

For modern vehicles, especially those with start-stop technology or high electrical demands, AGM represents the better solution. As vehicles become more complex and fuel efficiency requirements increase, AGM batteries will likely become standard, while flooded batteries continue serving basic applications.

Don’t just look at the price tag. Consider your total ownership costs, maintenance capability, and specific power requirements. The right battery isn’t the cheapest one—it’s the one that matches your needs and saves you money over its lifetime.