Ever wondered why some engines seem to have a “split personality” – quiet and efficient one minute, then roaring with power the next? Two revolutionary technologies are often behind this transformation: Honda’s VTEC and Toyota’s VVT-i. These competing valve timing systems have shaped modern engines, but they work in surprisingly different ways. Let’s dive into what makes each unique and which might be better for your driving needs.

What Are Variable Valve Timing Systems?

Variable valve timing systems solve a fundamental problem in engine design. Traditional fixed-valve engines face a frustrating compromise: optimize for low-end torque or high-end power – but not both. By dynamically adjusting how valves open and close, these systems deliver the best of both worlds.

Think of valves as the engine’s lungs. Controlling when and how they breathe makes all the difference in performance and efficiency. Variable valve timing technologies emerged in the late 1980s and 1990s as ingenious solutions to this challenge.

Honda’s VTEC: The Revolutionary Performance System

How VTEC Was Born

Honda’s VTEC (Variable Valve Timing and Electronic Lift Control) emerged from the company’s New Concept Engine program in 1984. With Japan’s heavy taxes on larger displacement engines, Honda needed smaller engines with big power. Engineer Ikuo Kajitani found inspiration in Honda’s motorcycle division, which had been experimenting with similar technology.

The first VTEC engine debuted in the 1989 Japanese Honda Integra, followed by the legendary 1990 Acura NSX for American markets. This innovation would forever change how performance engines were designed.

How VTEC Works

VTEC employs a clever mechanical system with two (or three) different cam profiles:

- A mild cam profile for everyday driving that prioritizes fuel economy

- An aggressive cam profile for high-RPM performance

The magic happens around 4,500-6,000 RPM when hydraulic pressure activates pins that lock the rocker arms together. This switches the valves to the high-performance cam profile, increasing valve lift and duration.

The result? That famous “VTEC just kicked in, yo!” sensation – a noticeable surge in power and a distinctive change in engine note that performance enthusiasts love.

VTEC Evolution

Honda hasn’t rested on its laurels. The i-VTEC system added continuous camshaft phasing (VTC) to the original VTEC, improving low-end torque while maintaining high-RPM power. Later versions like VTEC TURBO combined variable valve timing with forced induction for the best of all worlds.

Toyota’s VVT-i: The Efficiency Champion

VVT-i Origins

Toyota’s VVT-i (Variable Valve Timing-intelligent) arrived later than VTEC, debuting in 1995 as an evolution of Toyota’s earlier two-stage VVT system from 1991. While VTEC grabbed headlines with high-revving performance, Toyota took a more pragmatic approach focused on everyday efficiency and drivability.

The system first appeared in the Toyota Crown with the 2JZ-GE engine, promising 6% better fuel economy and 10% more torque in the critical low-to-mid RPM range where most daily driving occurs.

How VVT-i Works

Unlike VTEC’s complex rocker arm system, VVT-i focuses on continuously adjusting the timing of valve events by:

- Using oil pressure to rotate the camshaft relative to its sprocket

- Allowing the ECU to advance or retard valve timing based on driving conditions

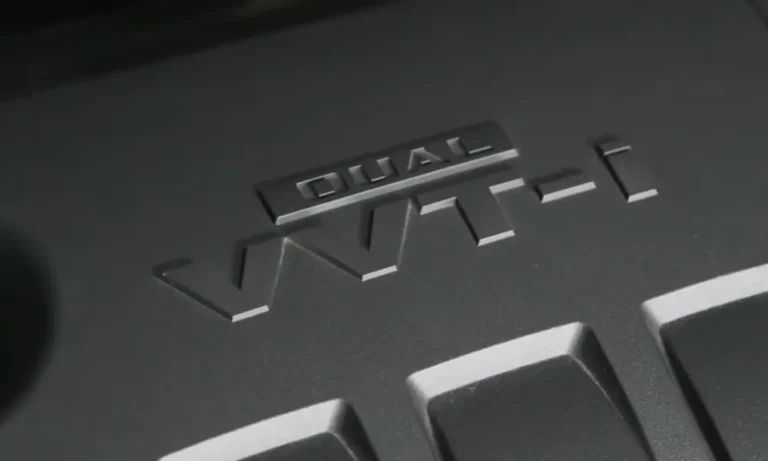

Early VVT-i systems only adjusted intake valve timing, while later Dual VVT-i controlled both intake and exhaust. What’s notable is the system’s seamlessness – there’s no sudden “kick” like with VTEC, just smooth, progressive power delivery that most drivers never consciously notice.

VVT-i Evolution

Toyota expanded the technology with several variants:

- Dual VVT-i: Controls both intake and exhaust camshafts

- VVTL-i: Added variable lift control similar to VTEC (used in sportier applications)

- VVT-iE: Uses electric motors instead of oil pressure for faster response

- VVT-iW: Enables Atkinson cycle operation for increased efficiency

Each iteration maintained Toyota’s focus on reliability while gradually improving performance.

VTEC vs VVT-i: The Technical Showdown

Let’s compare these systems head-to-head on the technical details:

| Feature | Honda VTEC | Toyota VVT-i |

|---|---|---|

| Primary Function | Switches between different cam profiles | Continuously adjusts camshaft timing |

| What It Controls | Valve lift, duration, and timing | Primarily valve timing (in base form) |

| Activation Method | Hydraulic pins lock rocker arms | Oil pressure adjusts camshaft phasing |

| Engagement | Distinct engagement at specific RPM | Gradual, continuous adjustment |

| Primary Benefit | High-RPM power | Improved efficiency and torque |

| Driver Experience | Noticeable power “kick” | Seamless operation |

| Complexity | More mechanical components | Simpler design |

This fundamental difference in approach reflects each company’s philosophy: Honda pursued excitement and performance, while Toyota prioritized refinement and efficiency.

Real-World Performance Differences

VTEC Performance Characteristics

Honda’s VTEC truly shines in high-performance applications:

- Enables small engines to produce surprising power (like the B16A squeezing 160hp from just 1.6 liters)

- Creates a thrilling two-stage power delivery that enthusiasts love

- Powers iconic performance cars like the Honda S2000, Civic Type R, and Integra Type R

- Allows engines to safely rev to higher RPMs thanks to milder cam timing during normal operation

The drawback? Early VTEC systems sacrificed some low-end torque and fuel efficiency to achieve their high-RPM magic.

VVT-i Performance Characteristics

Toyota’s approach delivers different benefits:

- Improves fuel economy by 5-10% across the entire RPM range

- Provides better low-end and mid-range torque for everyday driving

- Creates smoother power delivery without noticeable transition points

- Reduces emissions through more precise combustion control

- Requires less maintenance due to simpler design

The tradeoff is less excitement and character compared to VTEC engines, though later VVTL-i systems narrowed this gap.

Which System Is Better?

The answer depends entirely on your priorities:

Choose VTEC If You Value:

- Performance driving experience

- High-RPM power

- Emotional connection to your engine

- The thrill of feeling technology “engage”

Choose VVT-i If You Value:

- Maximum fuel efficiency

- Seamless everyday drivability

- Low maintenance costs

- Quieter operation

Many enthusiasts enjoy the characterful nature of VTEC engines, while practical drivers may never notice VVT-i working—which is exactly as Toyota intended.

Notable Vehicles Featuring Each Technology

Famous VTEC-Equipped Vehicles

- Acura NSX (1990-2005)

- Honda S2000 (1999-2009)

- Honda Civic Type R (all generations)

- Acura Integra Type R (1997-2001)

- Honda Accord Euro R (2000-2008)

Notable VVT-i-Equipped Vehicles

- Toyota Corolla (1998-present)

- Toyota Camry (late 1990s-present)

- Lexus IS300 (2001-2005)

- Toyota 86/GT86 (with VVTL-i in early models)

- Most modern Toyota and Lexus vehicles

Modern Developments and Future Outlook

Both technologies have evolved significantly:

Modern VTEC Systems

Honda’s latest Earth Dreams engines combine VTEC with direct injection and turbocharging. The newest iterations like VTEC TURBO focus on broader torque bands rather than high-RPM peaks, reflecting changing market demands and emissions regulations.

Modern VVT-i Systems

Toyota has integrated VVT-i with its hybrid technology, using electric actuation (VVT-iE) for faster response and more precise control. The system has become foundational to Toyota’s efficient four-cylinder engines across its lineup.

The Converging Future

Interestingly, both approaches have gradually converged. Honda’s i-VTEC added continuous timing control like VVT-i, while Toyota’s VVTL-i added variable lift like VTEC. Modern turbocharged engines rely less on high-RPM breathing and more on broad, flat torque curves that both companies now optimize for.

Maintenance Considerations

VTEC Maintenance Tips

- Use high-quality oil as recommended by Honda

- Change oil more frequently (especially in high-performance applications)

- Listen for abnormal noises during VTEC engagement

- Keep the VTEC solenoid and oil pressure switch clean

- Address any check engine lights promptly

VVT-i Maintenance Tips

- Follow Toyota’s recommended oil change intervals

- Use the correct oil weight to ensure proper VVT-i operation

- Keep oil clean to prevent VVT-i actuator clogging

- Have timing chain service performed at recommended intervals

The Verdict: Engineering Philosophies Made Real

The VTEC vs VVT-i comparison reveals more than just technical differences – it showcases two distinct approaches to solving the same engineering problem.

Honda’s VTEC represents the engineer as performance artist, creating a system with character and emotional appeal that encourages drivers to explore the engine’s capabilities. Toyota’s VVT-i embodies the engineer as efficiency expert, developing an invisible technology that quietly improves the driving experience without drawing attention to itself.

Neither approach is objectively “better” – they’re simply different expressions of engineering philosophy that have shaped automotive history and continue to influence engine design today. As mainstream manufacturers increasingly turn toward electrification, these innovative valve timing systems remain testament to the golden age of internal combustion engineering.