Are you searching for your 4L60E transmission control module without success? There’s a good reason for that. The 4L60E transmission doesn’t use a separate transmission control module at all. Instead, it relies on your vehicle’s main computer to handle transmission functions. Let’s clear up the confusion and help you understand exactly how your 4L60E transmission is controlled and where to find its brain.

The 4L60E Doesn’t Have a Separate TCM

If you’ve been looking around your engine bay for a standalone transmission control module (TCM) for your 4L60E, you can stop searching. The 4L60E transmission, used extensively by General Motors from 1993 through 2015, doesn’t have a dedicated TCM. Instead, transmission functions are managed by your vehicle’s Powertrain Control Module (PCM) or Engine Control Module (ECM).

This integrated approach means one computer handles both engine and transmission operations as a unified system. It’s a design choice GM made to streamline their electronic control systems and reduce component count across their vehicle lineup.

How the 4L60E Control System Works

The 4L60E represents a significant evolution from purely hydraulic transmissions, using electronic controls to manage shift timing, quality, and torque converter lockup. Here’s what makes it tick:

Key Components

- Shift solenoids A and B: Control gear selection

- Pressure control solenoid: Regulates line pressure

- Torque converter clutch solenoid: Controls lockup operation

- Multiple sensors: Monitor speed, fluid temperature, and other parameters

All these components receive their instructions directly from the PCM, which processes data from throughout the vehicle to determine the optimal transmission operation. Your throttle position, engine load, vehicle speed, and other factors all influence how the transmission behaves.

Where to Find Your PCM (The Actual Control Module)

Since the PCM controls your 4L60E transmission, knowing where to find it is essential for diagnostics or replacement. The location varies by vehicle model and year, but follows some consistent patterns across GM’s lineup.

Chevrolet Silverado and GMC Sierra Trucks (1999-2006)

In these popular trucks, you’ll typically find the PCM:

- On the driver’s side of the engine bay

- Near the firewall

- Often mounted on a bracket between the battery and firewall

- Sometimes partially hidden by the air intake or battery components

The PCM in these vehicles usually connects via two large multi-pin connectors with blue and red or blue and green housings.

Chevrolet Tahoe and Suburban SUVs (2000-2014)

For these larger SUVs equipped with the 4L60E:

- The PCM sits on the driver’s side engine compartment

- Positioned close to the firewall

- May require battery removal for best access during service

- Generally accessible without major disassembly

Identifying Your PCM Visually

The PCM appears as:

- A rectangular metal housing

- Typically about 8 inches × 6 inches × 2 inches

- Features multiple large electrical connectors

- Has a GM or Delco part number label (often starting with “12” or “16”)

- Usually secured with 2-4 mounting bolts

Common part numbers for 4L60E applications include 12200411, 12586243, and 09391347, though there are many different numbers depending on your specific vehicle.

How the PCM Connects to Your Transmission

While the PCM is the brain controlling your 4L60E, it doesn’t connect directly to the transmission. Instead:

- A main transmission connector on the passenger side of the transmission case serves as the interface

- This connector varies from 12 pins in early models to 17 pins in later versions

- It connects to the internal solenoid pack within the transmission’s valve body

- The solenoid pack contains the shift solenoids, pressure control solenoid, and torque converter clutch solenoid

- These components directly control hydraulic pressure and flow based on PCM commands

4L60E Control System Evolution Over Time

The 4L60E’s control system wasn’t static – it evolved substantially throughout its long production run:

| Years | Internal Connector Pins | Key Features Added |

|---|---|---|

| 1992-1993 | 12 pins | Base configuration |

| 1994-1995 | 13 pins | Added 3-2 downshift solenoid |

| 1996-2002 | 13 pins | Various calibration changes |

| 2003-2005 | 13 pins | Updated pressure control solenoid |

| 2006-2015 | 17 pins | Added input shaft speed sensor |

These evolutionary changes mean that PCM programming and connector pinouts vary significantly between model years. When troubleshooting, always verify your specific transmission variant before proceeding.

Common Diagnostic Challenges

Misconception About Separate TCM

The most common source of confusion stems from assuming the 4L60E has a standalone TCM. This misconception leads many to search for a component that doesn’t exist, wasting valuable diagnostic time.

Differentiating Control Issues from Mechanical Problems

While the PCM controls transmission operation, many 4L60E problems result from mechanical failures within the transmission itself, including:

- Worn clutch packs

- Failed solenoids

- Valve body issues

- Pressure regulator problems

Effective diagnosis requires testing both the control system and the transmission’s mechanical components methodically.

Important Service and Repair Tips

If you need to replace your PCM, keep these critical points in mind:

PCM Replacement Requires Programming

- New PCMs must be programmed to match your vehicle’s VIN and configuration

- Programming ensures proper engine and transmission calibration

- Incorrect programming may cause driveability issues or transmission performance problems

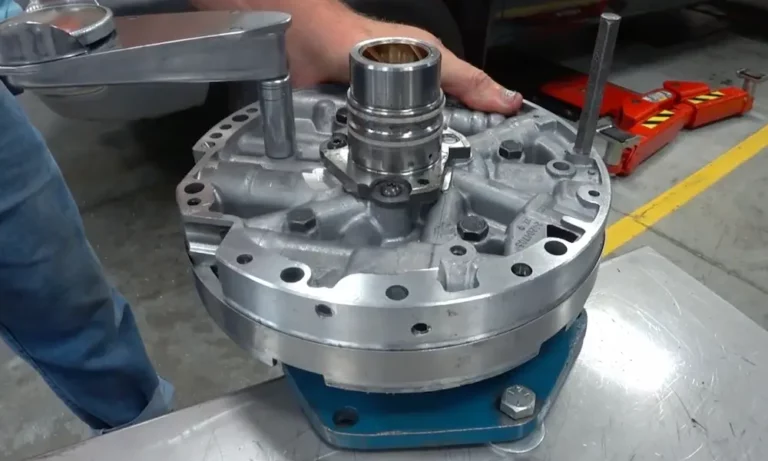

Transmission Solenoid Replacement Is Internal Work

When transmission solenoids need replacement:

- This requires internal transmission work, not PCM replacement

- The solenoid pack resides within the valve body inside the transmission

- Access requires transmission disassembly

- This job typically calls for specialized tools and expertise

Accessing Your PCM Safely

If you need to work with your PCM, follow these safety steps:

- Ensure the engine is cool before beginning

- Park on level ground with the parking brake engaged

- Remove the ignition key

- Disconnect the battery’s negative terminal

- Use caution when handling electronic components

- Protect connectors from dirt and moisture when disconnected

Step-by-Step PCM Location and Identification

- Open your vehicle’s hood and secure it properly

- Look to the driver’s side of the engine bay, near the firewall

- Identify the rectangular metal module with multiple wire connectors

- Check for GM/Delco part number labels

- Verify the connector colors (typically blue/red or blue/green)

- Note the mounting bracket and securing bolts

Why the 4L60E Uses PCM Control Instead of a Separate TCM

GM’s design choice to integrate transmission control within the PCM rather than using a separate TCM offered several advantages:

- Cost efficiency: Fewer components meant lower manufacturing costs

- Integration benefits: A single controller allowed better coordination between engine and transmission

- Simplification: Reduced wiring complexity and connector count

- Package space: Less need for mounting locations for multiple control modules

- Reliability: Fewer potential failure points in the control system

This approach reflected GM’s strategy of centralizing powertrain control functions within a single computer, setting the foundation for modern integrated vehicle electronic systems.

Common 4L60E PCM-Related Issues

When your 4L60E isn’t shifting properly, the issue might be PCM-related. Here are common symptoms and potential causes:

- Erratic shifting: May indicate PCM programming issues or sensor failures

- No shift or delayed shift: Could be solenoid failure or PCM communication problems

- Check engine light with transmission codes: Often points to control system issues

- Torque converter clutch not engaging: May be PCM command issue or solenoid failure

- Poor fuel economy: Could result from incorrect PCM management of transmission operation

For proper diagnosis, connecting a scan tool that can communicate with GM transmission parameters is essential.

Understanding Your 4L60E’s “Brain”

The great irony of searching for a 4L60E transmission control module is that there isn’t one – at least not as a separate component. Instead, your transmission relies on the PCM’s processing power to make shifting decisions.

This integrated approach was actually ahead of its time when introduced, as it allowed for better coordination between engine and transmission functions. The PCM uses input from numerous sensors to determine the optimal shifting strategy based on:

- Vehicle speed

- Throttle position

- Engine load

- Transmission fluid temperature

- Brake status

- Traction control inputs

- Engine temperature

- Battery voltage

All these factors are processed in real-time to deliver the best balance of performance and efficiency.

Working with Your 4L60E and PCM

Whether you’re troubleshooting issues or planning modifications, understanding the relationship between your PCM and 4L60E transmission is crucial. The PCM contains specific programming to manage shift points, pressure control, and torque converter lockup for your particular vehicle.

When modifying your vehicle, remember that engine changes often require PCM recalibration to maintain proper transmission function. Increased horsepower or torque may necessitate adjusted shift parameters and pressure control to prevent transmission damage.

Third-party tuning options exist that can optimize your 4L60E’s performance through PCM reprogramming, potentially offering benefits like firmer shifts, altered shift points, or modified torque converter lockup strategies.

By understanding that your 4L60E transmission control module is actually integrated within your PCM, you can better diagnose issues, plan modifications, and maintain your GM vehicle’s drivetrain for optimal performance and longevity.