Looking to understand what makes the 6.2 LS engine one of GM’s most celebrated powerplants? Whether you’re planning an engine swap, tuning for more power, or just appreciating American V8 engineering, this guide breaks down everything about this legendary engine. We’ll explore the exact specifications, applications, and why this pushrod V8 continues to dominate performance circles despite newer technologies.

What Is the 6.2 LS Engine?

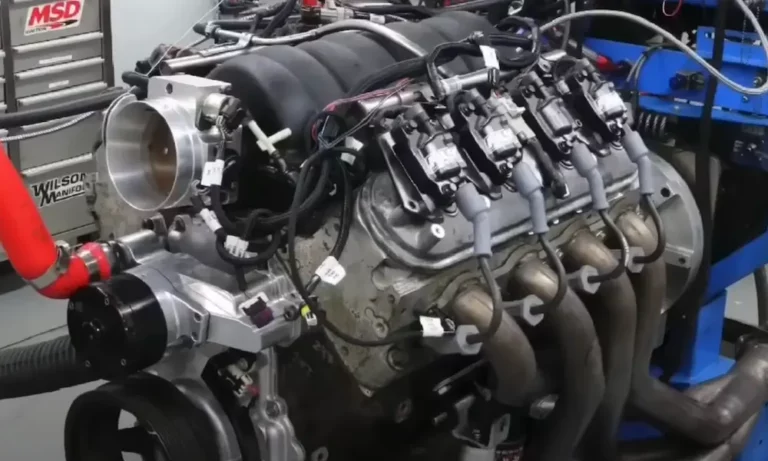

The 6.2 LS is part of General Motors’ LS-based small-block V8 engine family, representing the larger displacement offerings in the third and fourth generation small-block designs. Despite being introduced in an era when competitors were shifting to overhead cam designs, GM stuck with the traditional pushrod valve arrangement—a decision that paid off tremendously.

This engine architecture delivers impressive power in a compact, lightweight package that fits easily in engine bays while maintaining excellent reliability. The “LS” designation originally came from the Regular Production Option code for the first engine in this family (LS1), but has grown to represent the entire platform.

6.2 LS Engine Core Specifications

The 6.2L displacement translates to approximately 376 cubic inches, making it one of the larger offerings in the LS family. Here are the fundamental specs of the popular LS3 variant:

| Specification | LS3 6.2L Details |

|---|---|

| Displacement | 376 cu in (6.2L) |

| Bore x Stroke | 4.065 x 3.622 inches (103.25 x 92 mm) |

| Compression Ratio | 10.7:1 |

| Block Material | Cast aluminum |

| Cylinder Head Material | Cast aluminum |

| Valve Configuration | Overhead valve (pushrod) |

| Valvetrain | 2 valves per cylinder |

| Max RPM | 6,600 RPM |

| Horsepower | 430 hp @ 5,900 RPM |

| Torque | 424 lb-ft @ 4,600 RPM |

The 6.2L engine’s 4.065-inch bore and 3.622-inch stroke give it an excellent balance between torque production and high-RPM capability. The relatively large bore also allows for excellent breathing, especially when paired with the rectangular-port cylinder heads.

Block Design and Construction

The 6.2 LS engine block features several key engineering innovations that contribute to its impressive performance and durability:

Aluminum Block Construction

Unlike earlier small-blocks that used cast iron, most 6.2 LS engines feature aluminum block construction, reducing engine weight by nearly 100 pounds compared to older iron-block designs. This weight advantage improves overall vehicle dynamics and performance.

The block uses deep skirts for rigidity and employs six-bolt, cross-bolted main caps that secure the crankshaft with exceptional strength. This robust design allows the engine to handle substantial power increases through modifications.

Cooling System Design

The 6.2 LS block incorporates improved coolant passages compared to earlier generations, with priority main bearing oiling and enhanced cylinder cooling. This design helps maintain consistent temperatures under high load, preventing hot spots that could lead to detonation.

The cooling system routes coolant through the heads first before returning to the block, which helps control cylinder head temperatures where they’re most critical for preventing detonation.

Rotating Assembly Specifications

The internals of the 6.2 LS engine are engineered for durability while maintaining reasonable production costs:

Crankshaft and Connecting Rods

The standard 6.2 LS3 uses a nodular iron crankshaft, offering excellent strength while keeping costs down compared to forged steel alternatives. The crank features rolled fillets for improved strength at the journals.

The connecting rods are made using powdered metal technology, which produces components with consistent quality at scale. These rods are considerably stronger than the forged steel components used in earlier small-block generations, despite appearing less robust to the untrained eye.

Pistons and Rings

The LS3 6.2L employs hypereutectic aluminum pistons with a durable coating to reduce friction. These pistons feature a flat top design with valve reliefs and are built to handle the 10.7:1 compression ratio while running on premium pump fuel.

The ring package uses thin, low-tension rings that reduce friction while maintaining excellent sealing. This design contributes to both power output and fuel efficiency advantages.

Cylinder Head Technology

The cylinder heads are perhaps the most significant contributors to the 6.2 LS engine’s impressive power output:

L92-Style Rectangular Ports

The LS3 uses L92-style cylinder heads with rectangular intake ports that dramatically improve airflow compared to the cathedral-port designs of earlier LS engines. These heads feature “as cast” 68cc combustion chambers that help achieve the 10.7:1 compression ratio.

The intake ports flow approximately 315 cfm at 0.600″ lift, which is exceptional for a production cylinder head and contributes significantly to the engine’s high-RPM breathing ability.

Valve Specifications

Valve sizes are generously proportioned:

- Intake valves: 2.165 inches

- Exhaust valves: 1.590 inches

These large valves, combined with the excellent port design, allow for tremendous airflow potential even without porting. The valvetrain uses investment-cast rocker arms with roller trunnions operating at a 1.7:1 ratio.

Camshaft Specifications

The camshaft specifications play a crucial role in determining the engine’s power delivery and RPM range:

Factory LS3 Camshaft Specs

The standard LS3 6.2L employs a hydraulic roller camshaft with the following specifications:

- Valve lift: 0.551 inches (intake) / 0.522 inches (exhaust)

- Duration at 0.050″: 204 degrees (intake) / 211 degrees (exhaust)

- Lobe separation angle: 117 degrees

This relatively aggressive factory camshaft helps the engine produce excellent top-end power while maintaining good drivability and low-end torque. The hydraulic roller design eliminates the need for periodic valve adjustments while reducing internal friction.

Engine Management Systems

The 6.2 LS engines use sophisticated engine management systems that contribute significantly to their performance and efficiency:

Electronic Control Module

Modern 6.2 LS engines utilize a 58-tooth reluctor wheel for precise crankshaft position sensing, enabling accurate ignition timing and fuel delivery. This system provides far more precise control than earlier GM engine management systems.

For crate engine installations, GM offers controller kits like the 19354328, which includes the necessary ECM, wiring harness, and electronic throttle pedal required for non-factory applications.

Factory Applications of the 6.2 LS Engine

The 6.2 LS engine has powered numerous high-performance vehicles in GM’s lineup:

Popular Vehicle Applications

- Chevrolet Corvette (C6)

- Chevrolet Camaro SS (fifth generation)

- Pontiac G8 GXP

- Chevrolet SS sedan

- Cadillac CTS-V (some variants)

- GMC Sierra and Chevrolet Silverado (performance variants)

- Various specialty and limited-edition vehicles

Each application may feature specific tuning differences or accessory systems, but the core engine architecture remains consistent across these platforms.

LS3 6.2L Crate Engine Options

For those looking to install a 6.2 LS engine in a project car, GM offers several crate engine packages:

Installation Considerations

When purchasing a 6.2 LS crate engine, be aware that standard packages typically don’t include:

- Engine control electronics

- Flexplate or flywheel

- Exhaust manifolds

- Intake manifold (in some packages)

The oil pan configuration is particularly important for engine swaps. The standard LS3 crate engine comes with a Chevy SS mid-wet sump oil pan, which fits specific chassis like the 2010-15 Camaro SS/ZL1, 2012-15 Caprice PPV, 2014-15 Chevy SS, and 2008-09 Pontiac G8. However, this pan isn’t compatible with many classic muscle car LS engine swaps without modification.

Performance Potential and Modifications

The 6.2 LS engine responds exceptionally well to modifications, making it a favorite among performance enthusiasts:

Common Performance Upgrades

- Camshaft Upgrades: Aftermarket camshafts with more aggressive profiles can unlock significant power, with gains of 30-50 horsepower common with proper supporting modifications.

- Cylinder Head Porting: Even basic porting work on the already-efficient LS3 heads can yield noticeable airflow improvements, supporting higher power levels.

- Intake Manifold Options: Aftermarket intake manifolds with larger plenums and runners can improve high-RPM power, with designs available for different power bands and applications.

- Forced Induction: The 6.2 LS responds exceptionally well to supercharging and turbocharging, with properly built engines capable of reliably handling over 1,000 horsepower.

- Stroker Kits: Increasing displacement to 6.7L (408ci) or even 7.0L (427ci) with stroker kits can significantly increase torque output while maintaining the engine’s excellent response.

Why The 6.2 LS Engine Remains Popular

Despite newer technologies on the market, the 6.2 LS engine continues to dominate performance applications for several compelling reasons:

Compact Design

The pushrod architecture results in a much smaller package than overhead cam designs of similar displacement. This compactness allows the engine to fit in a wide variety of vehicles not originally designed for V8 power.

Exceptional Power Density

Few production engines can match the horsepower-per-cubic-inch and horsepower-per-pound ratios of the 6.2 LS. This efficient power delivery makes it ideal for performance applications where power-to-weight ratio matters.

Robust Design

The 6.2 LS was engineered with significant safety margins, allowing it to handle substantial power increases without requiring extensive internal modifications. This overbuilt nature contributes to the engine’s legendary reliability even when modified.

Massive Aftermarket Support

Few engines enjoy the level of aftermarket support available for the 6.2 LS. From basic maintenance parts to exotic performance components, the availability of parts at various price points makes building and maintaining these engines relatively straightforward.

Comparing 6.2 LS Variants

Not all 6.2 LS engines are identical. Here’s how some key variants compare:

| Variant | Horsepower | Torque | Key Features | Common Applications |

|---|---|---|---|---|

| LS3 | 430 hp | 424 lb-ft | Rectangular port heads | Corvette, Camaro SS |

| L92 | 403 hp | 415 lb-ft | Variable valve timing | GM trucks/SUVs |

| L94 | 403 hp | 415 lb-ft | VVT, Active Fuel Management | Cadillac Escalade |

| LSA | 556-580 hp | 551-556 lb-ft | Supercharged | CTS-V, ZL1 Camaro |

| LS9 | 638 hp | 604 lb-ft | Supercharged, forged internals | Corvette ZR1 |

While these variants share the same basic architecture and displacement, their specific components and tuning create different performance characteristics tailored to their intended applications.

Engine Swap Considerations

The 6.2 LS engine’s popularity for engine swaps is well-deserved, but several considerations are essential for a successful conversion:

Physical Fitment

While the LS is compact for its displacement, accessory placement, exhaust routing, and oil pan clearance require careful planning. Aftermarket companies offer specific oil pans, headers, and accessory relocation kits designed for popular swaps.

Electronics Integration

Modern LS engines require electronic control systems. Options include:

- Factory ECM with modified programming

- Standalone aftermarket ECMs

- Simplified harnesses that eliminate unnecessary features

Transmission Compatibility

The 6.2 LS can be paired with various transmissions, including:

- Modern GM automatics (4L60E, 4L80E, 6L80E)

- Older GM automatics with adapter plates

- Manual transmissions (T56, TR6060)

- Non-GM transmissions with appropriate adapters

Maintenance Requirements

One advantage of the 6.2 LS engine is its relatively straightforward maintenance requirements:

- Oil changes: Typically 5-7 quarts of 5W-30 synthetic oil

- Spark plugs: Usually replaced every 100,000 miles in stock applications

- Ignition coils: Generally very reliable but can fail on high-mileage engines

- Valve adjustment: Not required due to hydraulic lifters

The engine’s design eliminates timing belts and complex variable valve timing systems (on most variants), reducing maintenance compared to some competitor engines.

The Future of the 6.2 LS Engine

Despite increasing electrification in the automotive industry, the 6.2 LS engine architecture continues to evolve:

The latest 6.2L engines in GM’s lineup include technologies like Dynamic Fuel Management (DFM), which can deactivate cylinders in various patterns to improve efficiency while maintaining the power potential enthusiasts expect.

Even as emissions regulations tighten, the fundamental strengths of the 6.2 LS design ensure its continued relevance in performance applications and the aftermarket for years to come.

Key Technical Innovations in the 6.2 LS Engine

Several technical innovations contribute to the 6.2 LS engine’s exceptional performance and durability:

Advanced Casting Techniques

GM pioneered semi-permanent mold casting for the aluminum blocks, providing superior strength and consistency compared to traditional sand casting methods. This approach allows for thinner walls and lighter weight while maintaining necessary durability.

Efficient Cooling Design

The 6.2 LS features a revised cooling layout that maintains more even cylinder temperatures, reducing distortion and improving ring sealing under high-load conditions.

Optimized Combustion Chamber Design

The combustion chambers are engineered for efficient flame propagation, contributing to both power output and emissions compliance. This design allows for the relatively high compression ratio while still functioning well on pump gasoline.

The 6.2 LS engine represents an impressive balance of traditional American V8 architecture with modern engineering advancements—proof that sometimes the best approach isn’t always the most technologically complex, but rather the most effectively executed.