Thinking about a diesel engine that delivers impressive torque in a compact package? The Cummins 4BT might be exactly what you need. This 3.9-liter turbocharged diesel has earned a devoted following for good reason – it combines industrial-grade durability with surprising versatility. Whether you’re planning a vehicle conversion or need a reliable power source for your equipment, understanding the 4BT’s specifications is your first step toward making an informed decision.

What Is the Cummins 4BT Engine?

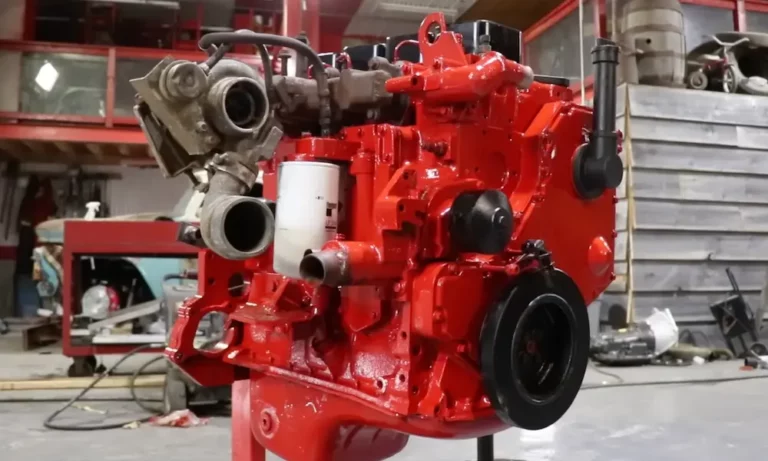

The Cummins 4BT is a 3.9-liter inline four-cylinder turbocharged diesel engine that essentially serves as the smaller sibling to the more famous 5.9L Cummins found in Ram trucks. The name itself tells you a lot – “4” represents four cylinders, “B” identifies it as part of Cummins’ B-series family, and “T” stands for turbocharged.

Originally designed for commercial applications like delivery trucks and bread vans in the 1980s, the 4BT has since found its way into everything from boats to Jeeps. Its appeal lies in delivering substantial torque in a relatively compact package with legendary reliability.

Core Engine Specifications

The 4BT’s fundamental specs create the foundation for its performance capabilities:

| Specification | Details |

|---|---|

| Displacement | 3.9 liters (239 cubic inches) |

| Configuration | Inline 4-cylinder |

| Bore x Stroke | 4.02″ x 4.72″ (102mm x 120mm) |

| Compression Ratio | 17.5:1 |

| Block/Head Material | Cast iron |

| Valvetrain | 2 valves per cylinder (8 valves total) in early models; 4 valves per cylinder (16 valves) in post-1998 models |

| Weight | Approximately 750 pounds (340 kg) |

| Dimensions (WxLxH) | 23.35″ x 30.50″ x 37.87″ (593mm x 775mm x 962mm) |

The engine’s cast iron construction contributes significantly to its weight but also to its legendary durability. While 750 pounds might seem heavy for a four-cylinder engine, this robust construction is precisely what enables the 4BT to handle the demands of heavy-duty applications for hundreds of thousands of miles.

Performance and Output Specifications

The 4BT’s performance numbers tell the story of an engine built for torque rather than high-revving horsepower:

| Specification | Original 4BT | Later 4BTA (post-1998) |

|---|---|---|

| Horsepower | 105 hp @ 2,300 RPM | Up to 170 hp |

| Torque | 265 lb-ft @ 1,600 RPM | Up to 440 lb-ft |

| Redline | ~3,000 RPM | ~3,000 RPM |

The engine’s relatively modest horsepower figures might not impress at first glance, but the substantial low-end torque makes it exceptionally capable for towing, hauling, and off-road applications. The later 4BTA variants with 16-valve heads saw significant performance improvements while maintaining the core characteristics that made the 4BT popular.

For marine applications, the 4BT can deliver up to 150 horsepower at 2,800 RPM with torque ratings reaching 300 lb-ft at 2,200 RPM, making it suitable for smaller vessels where space is at a premium.

Fuel and Injection System

The 4BT’s fuel delivery system contributes significantly to its performance characteristics and reliability:

| Component | Specification |

|---|---|

| Fuel System | Direct injection |

| Injection Pump | Early: Stanadyne DB4; Later: Bosch P7100 (P-pump) |

| Filtration | Fleetguard spin-on fuel filters |

| Fuel Economy | Varies by application but generally favorable for output class |

The Bosch P7100 injection pump found on most 4BTs is particularly noteworthy. This mechanical inline pump is prized for its durability and tunability, allowing for substantial performance modifications. The pump’s mechanical (rather than electronic) nature contributes to the engine’s simplicity and field serviceability – a key reason why the 4BT remains popular in remote locations or with DIY-minded owners.

Cooling and Lubrication Specifications

Proper cooling and lubrication are crucial for any diesel engine’s durability, and the 4BT features robust systems for both:

| System | Specification |

|---|---|

| Cooling System Capacity | 7.2 liters (1.9 U.S. gallons) |

| Oil Capacity | 10.9 liters (2.9 U.S. gallons) |

| Oil Filtration | Full-flow lubricating oil system |

| Cooling Options | Heat exchanger or keel cooled (marine applications) |

The 4BT typically uses a Holset HX30 turbocharger mounted at the top of the engine, providing improved power, better fuel economy, and altitude compensation compared to naturally aspirated designs. This turbocharger arrangement helps the engine maintain performance across varied operating conditions.

Applications and Versatility

The 4BT’s combination of size, power, and reliability has made it suitable for an impressive range of applications:

Commercial and Industrial Applications

- Delivery trucks and vans

- Construction equipment

- Agricultural machinery

- Generator sets (64-102 BHP depending on duty cycle)

- Forklifts and small industrial equipment

Marine Applications

- Small to medium fishing vessels

- Recreational boats

- Auxiliary power systems

- Available in heat exchanger or keel cooled configurations

Vehicle Conversions

- Jeeps and off-road vehicles

- Land Rover and vintage 4×4 swaps

- Custom vehicle builds

- Military vehicle repowers

This versatility has created a thriving aftermarket for the 4BT, with numerous companies specializing in engine mounts, adaptors, and conversion kits to simplify installation across various platforms.

Evolution and Variants

The 4BT has evolved throughout its production life, with several key variants:

Original 4BT (1983-1998)

- 8-valve cylinder head design (2 valves per cylinder)

- 105 horsepower and 265 lb-ft of torque

- Primarily mechanical components

4BTA (Post-1998)

- 16-valve cylinder head design (4 valves per cylinder)

- Up to 170 horsepower and 440 lb-ft of torque

- Improved efficiency and performance

Modern Equivalents

- 4.5-liter ISB and QSB engines represent the contemporary evolution

- Incorporate advanced electronic controls

- Meet modern emissions standards (Euro 5 and Euro 6)

- Produce up to 185 horsepower

Despite newer alternatives, the original 4BT maintains a strong following, particularly where mechanical simplicity and ease of service take priority over the latest electronic features.

Durability and Service Life

The 4BT Cummins is renowned for its longevity when properly maintained:

- Expected service life of 350,000+ miles before major overhaul in automotive applications

- Marine and industrial variants often see 20,000+ hours of operation

- Five main bearing design provides optimal crankshaft support

- Shares many components with the larger 6BT, including:

- Pistons

- Connecting rods

- Injectors

- Injection pump

- Valvetrain components

This parts commonality with the 6BT (5.9L) Cummins has proven advantageous for owners, as the widespread availability of components for the popular 5.9L engine benefits the 4BT platform as well.

Advantages and Limitations of the 4BT

Understanding both the strengths and weaknesses of the 4BT helps determine if it’s the right choice for your application.

Advantages

- Exceptional durability and longevity

- Strong low-end torque suitable for towing and hauling

- Compact dimensions compared to V8 diesels of similar capability

- Mechanical fuel system requires minimal electronics

- Excellent parts availability and aftermarket support

- Can operate at elevations up to 4,000 feet without power loss

- Performs well in extreme temperatures

Limitations

- Heavy for its size (750 pounds)

- Moderate NVH (noise, vibration, harshness) characteristics

- Limited high-RPM power compared to gasoline alternatives

- Older technology lacks some modern emissions controls

- Can require significant modification for some vehicle conversions

Conversion and Upgrade Options

For those considering the 4BT for a custom application, numerous performance upgrades and conversion options exist:

Performance Upgrades

- Upgraded turbochargers

- Modified fuel pumps and larger injectors

- Performance camshafts

- Improved intake and exhaust systems

- Electronic tuning modules for later variants

Conversion Components

- Custom engine mounts for various vehicles

- Bellhousing adapters for different transmissions

- Cooling system modifications

- Upgraded clutch systems for manual transmissions

- Electronic interface systems for modern vehicle integration

These options have created a robust ecosystem around the 4BT, making it a popular choice for custom builds despite being an older design. Companies like Diesel Pro specialize in conversion components and performance parts specifically for this engine.

Finding and Sourcing a 4BT Engine

If you’re interested in acquiring a 4BT for your project, several sourcing options exist:

- Remanufactured engines from Cummins Recon program

- Specialized diesel engine suppliers

- Salvage from retired commercial vehicles

- Marine equipment suppliers for boat applications

- Dedicated 4BT resellers and rebuilders

Prices vary significantly based on condition, completeness, and whether the engine is remanufactured or used. A complete running engine typically ranges from $3,000 to $7,000 depending on specifications and source.

When purchasing, proper documentation of the engine’s history and a compression test are highly recommended to verify its condition.

Modern Alternatives to the 4BT

While the 4BT remains popular, newer alternatives might better suit certain applications:

- Cummins R2.8 (2.8L): Lighter, more modern 4-cylinder with 161 hp and 267 lb-ft

- Cummins 4.5L ISB: The contemporary evolution with electronic controls

- Power Stroke 3.2L: Found in Transit vans, offers modern emissions compliance

- Isuzu 4BD1/4BD2: Similar size and capability with lighter weight

Each alternative offers different trade-offs in terms of weight, power, emissions compliance, and electronic complexity.

The Enduring Appeal of the 4BT

Despite being an older design, the 4BT Cummins continues to attract enthusiasts and professionals alike. Its combination of compact dimensions, impressive torque, and legendary durability creates a package that remains compelling even in the age of electronically controlled engines.

For applications where reliability trumps cutting-edge technology, where mechanical simplicity is an advantage rather than a limitation, and where robust construction matters more than lightweight design, the 4BT continues to prove its worth.

Whether powering a custom Jeep through challenging terrain, providing reliable propulsion for a fishing vessel, or serving as the heart of a generator in a remote location, the 4BT’s fundamental engineering virtues ensure its continued relevance across diverse applications worldwide.