Strange engine behavior? Check engine light glowing on your dashboard? If your mechanic mentioned something about “cylinder deactivation system bank 1,” you’re in the right place. This fuel-saving technology can be a bit confusing, but I’ll break it down into simple terms that’ll help you understand what’s happening under your hood and what you can do about it.

What Is Cylinder Deactivation Technology?

Cylinder deactivation is a clever fuel-saving feature in modern engines that temporarily shuts down some cylinders when you don’t need full power. Think of it like turning off lights in rooms you’re not using – why waste energy when it’s not needed?

This technology (sometimes called variable displacement) works by closing both intake and exhaust valves for specific cylinders while cutting off their fuel supply when you’re cruising at steady speeds. The result? Better fuel economy with minimal impact on performance.

During light-load driving (like highway cruising), your engine typically runs at only 30% of its maximum power. By deactivating cylinders, the remaining active ones work more efficiently, reducing wasted energy and improving fuel consumption by 5-20% depending on the system.

What Does “Bank 1” Actually Mean?

In the world of engines, “bank” simply refers to a specific side or group of cylinders. Bank 1 is always the side that contains cylinder #1 – that’s the universal definition across all manufacturers. But here’s where it gets tricky: the physical location of bank 1 varies between different car makes and models.

For V-shaped engines (like V6s or V8s):

- General Motors and Chrysler: Bank 1 is typically on the driver’s side

- Ford: Bank 1 is often on the passenger side

- Honda: In their V6 engines, bank 1 is usually the rear bank (closest to the firewall)

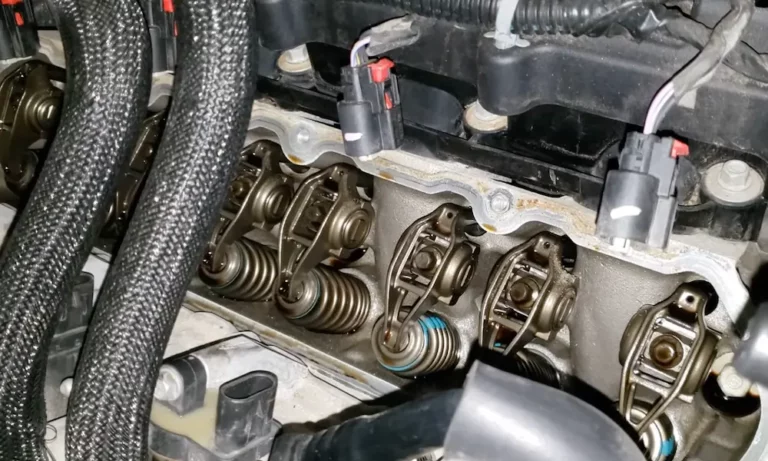

Finding bank 1 becomes important when diagnosing problems, as error codes often specify which bank has issues. If you’re trying to locate bank 1 on your specific vehicle, this visual guide can help identify the correct side.

How Cylinder Deactivation Systems Work

The magic behind cylinder deactivation involves some impressive engineering. Here’s what happens when you’re cruising down the highway:

- Your engine computer constantly monitors conditions (speed, throttle position, engine load)

- When conditions are right, the system activates in just 0.04 seconds (faster than you can blink)

- Special hydraulic mechanisms disengage the valves in selected cylinders

- The deactivated cylinders create an “air spring” effect where trapped gases compress and decompress

- The remaining cylinders work harder but more efficiently

- When you need more power, all cylinders reactivate instantly

This transition happens so smoothly you likely won’t notice when half your engine shuts down and restarts. The only clue might be a subtle change in engine sound or a dashboard indicator in some vehicles.

Comparing Major Manufacturer Systems

Let’s look at how different automakers have implemented this technology:

GM’s Active Fuel Management (AFM)

General Motors introduced Active Fuel Management in 2005 for their V8 engines. The system:

- Typically deactivates 4 cylinders in V8 engines (running on 4 cylinders during light loads)

- Uses specialized hydraulic lifters that collapse when oil pressure is applied

- Improves fuel economy by 5-7% under ideal conditions

- Employs unique camshaft profiles for the deactivated cylinders

The system requires specific components including special AFM lifters and valley cover assemblies. When functioning properly, the transition between 8 and 4 cylinders is virtually undetectable.

Honda’s Variable Cylinder Management (VCM)

Honda’s approach differs from American manufacturers by using overhead cam technology instead of a pushrod design:

- Uses a sliding pin mechanism that disconnects cam followers from rockers

- Evolved through multiple generations (VCM, VCM-2, VCM-3)

- Can operate in 3, 4, or 6-cylinder modes depending on the version

- Achieves 8-12% fuel economy improvements

- Has experienced some reliability issues with piston rings and oil consumption

This technology appears in many Honda V6 engines, including those in the Odyssey, Pilot, and Accord models.

Chrysler’s Multi-Displacement System (MDS)

Chrysler’s MDS debuted in 2005 on their iconic 5.7L HEMI V8 engines:

- Deactivates cylinders 1, 4, 6, and 7 during light loads

- Uses four MDS solenoids located in the engine valley

- Can improve fuel economy by up to 20% – among the best in the industry

- Features a special exhaust system with four mufflers to maintain the V8 sound even in 4-cylinder mode

This system requires proper oil temperature and pressure to work effectively, making regular maintenance especially important.

Common Cylinder Deactivation System Problems

While cylinder deactivation technology improves fuel efficiency, it does introduce additional complexity and potential failure points. Here are the most common issues by manufacturer:

GM AFM Problems

The most frequent issue in General Motors vehicles is lifter failure. Symptoms include:

- Ticking or knocking noises

- Rough idle

- Check engine light with specific AFM-related codes

- Reduced power

- Oil consumption

When AFM lifters fail, they often require complete replacement along with cam modifications in severe cases.

Honda VCM Issues

Honda’s system commonly experiences:

- Piston ring problems

- Oil consumption

- Vibration at specific speeds

- Engine hesitation

- Premature spark plug wear

These issues often result from the vacuum effect created in deactivated cylinders, which can pull oil past the rings over time.

Chrysler MDS Troubles

In Chrysler vehicles, look for:

- Solenoid failures (especially when plastic housings become brittle)

- Irregular shifting between 4 and 8-cylinder modes

- Engine misfires

- Check engine light with MDS-related codes

Improved aluminum-housed replacement solenoids can address recurring solenoid failures.

Cylinder Deactivation Diagnostic Codes

When your cylinder deactivation system encounters problems, your vehicle’s computer stores specific error codes. The most common bank 1 related codes include:

| Error Code | Description | Common Causes |

|---|---|---|

| P3400 | Cylinder Deactivation System Bank 1 | Low oil pressure, faulty solenoids, wiring issues |

| P3401 | Cylinder 1 Deactivation Intake Valve Control Circuit Open | Open circuit, damaged wiring |

| P3402 | Cylinder 1 Performance Problems | Mechanical valve issues, lifter failure |

| P3403 | Cylinder 1 Low Voltage | Electrical problems, poor connections |

| P3404 | Cylinder 1 High Voltage | Short circuits, control module issues |

The diagnostic process typically starts with checking engine oil level and pressure, since most cylinder deactivation systems rely on hydraulic pressure. Low oil levels or contaminated oil can trigger multiple codes simultaneously and prevent proper system function.

When these codes appear, systematic troubleshooting should begin with the basics:

- Check oil level and condition

- Verify proper oil pressure

- Inspect wiring connectors

- Test solenoid function

- Look for mechanical issues with lifters or actuators

Maintaining Your Cylinder Deactivation System

To keep your cylinder deactivation system in top shape:

Use the Right Oil

These systems rely heavily on precise oil pressure and flow. Always use:

- The exact oil viscosity recommended by your manufacturer

- High-quality oils that meet or exceed specifications

- Fresh oil (change at or before recommended intervals)

Keep Up With Regular Maintenance

Beyond oil changes, pay attention to:

- Air filter condition (restricted airflow affects engine load detection)

- Spark plug condition and replacement intervals

- Fuel system cleanliness

- Battery voltage (systems may disable during low voltage conditions)

Consider Driving Habits

How you drive impacts system operation and longevity:

- Long highway drives give the system time to operate in its most efficient mode

- Frequent short trips or stop-and-go driving reduces the benefits

- Towing or heavy loads often prevent the system from activating

Is Cylinder Deactivation Deletion an Option?

Some owners choose to disable their cylinder deactivation systems entirely through aftermarket solutions. While this eliminates fuel economy benefits, it can prevent costly repairs for engines prone to problems.

Available options include:

- Electronic control modules that trick the system

- Mechanical delete kits that replace variable lifters with standard parts

- Software reprogramming (requires professional service)

Before choosing this route, understand that:

- Fuel economy will decrease by 5-20%

- It may affect emissions compliance in some regions

- Some solutions are more reversible than others

For many high-mileage vehicles, especially those with documented reliability issues, the trade-off can make sense financially.

System Effectiveness and Fuel Economy Impact

How much fuel does cylinder deactivation actually save? The numbers vary by manufacturer and implementation:

| System | Typical Fuel Economy Improvement | Best Operating Conditions |

|---|---|---|

| GM AFM | 5-7% | Highway cruising 40-70 mph |

| Honda VCM | 8-12% | Steady speeds, light throttle |

| Chrysler MDS | 10-20% | Constant speed highway driving |

These savings are most noticeable during highway driving when the system can remain in its efficient mode for extended periods. City driving or aggressive acceleration offers minimal benefits since all cylinders remain active.

Engine Protection During Cylinder Deactivation

Modern engines include several safeguards to protect deactivated cylinders:

- Oil control rings help prevent oil consumption in idle cylinders

- Temperature sensors prevent deactivation until proper operating temperature

- Load monitors reactivate all cylinders during demanding conditions

- Adaptive learning adjusts operation based on driving conditions

These protections help explain why most drivers never notice when the system activates – it’s designed to operate only when conditions are perfect for trouble-free operation.

Final Thoughts on Cylinder Deactivation System Bank 1

Cylinder deactivation represents an impressive engineering solution that helps internal combustion engines remain competitive in an increasingly efficiency-focused world. While the technology isn’t perfect and can introduce maintenance challenges, proper care can help maximize the benefits while minimizing potential issues.

Understanding the specifics of your vehicle’s system – particularly the location and operation of bank 1 – provides valuable knowledge when diagnosing problems or discussing repairs with your mechanic. Whether you’re trying to resolve a check engine light or simply curious about how your vehicle saves fuel, this technology showcases how modern engines continue to find new efficiencies in century-old combustion principles.