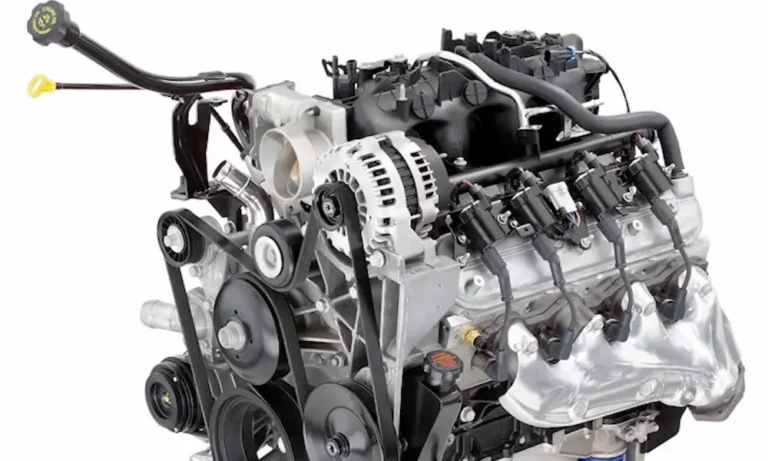

Ready to drop a heavyweight GM powerplant into your project? You’re likely eyeing the popular 6.0L V8 siblings – the LQ4 and LQ9. These iron block monsters have powered everything from workhorse trucks to luxury SUVs, but choosing between them isn’t as straightforward as you might think. Let’s dive into what makes these engines tick and which one deserves your hard-earned cash.

The Origin Story: How These LS Cousins Came to Be

The LQ4 and LQ9 engines emerged from GM’s revolutionary LS platform that debuted in 1997. While the Corvette got the aluminum-block LS1, trucks and SUVs received these beefier cast iron versions built for durability.

The LQ4 (aka Vortec 6000) arrived first in 1999, serving as the reliable muscle in Chevy Silverados and GMC Sierras. The LQ9 (Vortec HO 6000 or Vortec Max) joined the family later in 2002, targeting premium vehicles like the Cadillac Escalade with enhanced performance characteristics.

Both engines share the classic LS DNA – 4.40-inch bore spacing and the pushrod valvetrain that made these engines compact powerhouses. But GM ended production of both in 2007, replaced by the Gen IV variants with more advanced features.

Block and Heads: The Foundation of Power

Both engines use a cast iron block with six-bolt main caps that provide exceptional strength – a huge advantage for heavy-duty applications or power adders. The differences between the two show up in the details:

LQ4 Block Details:

- Cast iron construction

- 4.0-inch bore

- 3.622-inch stroke

- Early models (1999-2000) had cast iron heads

- Later switched to aluminum heads (71cc chambers)

- 9.4:1 compression ratio

- Dished pistons (-8cc volume)

LQ9 Block Details:

- Same cast iron construction

- Identical bore and stroke dimensions

- Aluminum heads throughout production

- Higher 10.0-10.4:1 compression ratio

- Flat-top pistons (+2cc volume)

This higher compression ratio is the LQ9’s defining characteristic, giving it a noticeable performance edge without sacrificing reliability. The machining differences between the blocks are subtle but important for accommodating the different compression specifications.

Power Output: The Numbers That Matter

When you’re comparing engines, power figures tell much of the story. Here’s how these two stack up:

LQ4:

- 300-330 hp (depending on year/application)

- 360-370 lb-ft of torque

- Power peak: 4,400 RPM

- Torque peak: 4,000 RPM

LQ9:

- 345 hp

- 380 lb-ft of torque

- Power peak: 5,200 RPM

- Torque peak: 4,200 RPM

The LQ9 delivers about 15-20% more horsepower than the LQ4, with independent dyno tests showing gains of 24 hp and 20 lb-ft over the LQ4, particularly above 4,500 RPM. This makes the LQ9 more rewarding when pushed hard, while the LQ4’s flatter torque curve works well for towing and everyday driving.

Camshaft and Valvetrain: The Heart of the Beast

The camshaft profile plays a huge role in an engine’s character, and here’s where we see more distinctions:

LQ4 Cam Specs:

- 196° intake duration (at 0.050″)

- 201° exhaust duration

- 0.467″ intake valve lift

- 0.479″ exhaust valve lift

- 1.7:1 rocker arms

- Hydraulic roller lifters

LQ9 Cam Specs:

- 196° intake duration

- 207° exhaust duration

- 0.467″ intake valve lift

- 0.479″ exhaust valve lift

The LQ9’s slightly more aggressive exhaust duration helps it breathe better at higher RPMs, contributing to its higher power rating. Both engines use the same basic valvetrain components, making upgrades interchangeable between the platforms.

Vehicle Applications: Where You’ll Find Them

Knowing which vehicles these engines came in helps when you’re hunting for a donor:

LQ4-Equipped Vehicles (1999-2007):

- Chevrolet Silverado 2500/3500

- Chevrolet Suburban

- Chevrolet Express Van

- GMC Sierra 2500/3500

- GMC Yukon XL

- VIN Code: U

LQ9-Equipped Vehicles (2002-2007):

- Cadillac Escalade

- GMC Sierra Denali

- GMC Yukon Denali

- Chevrolet SSR (select years)

- VIN Code: N

The LQ9’s premium vehicle applications reflect its performance-oriented design, while the LQ4’s broader use in workhorse vehicles speaks to its durability and utility focus.

Aftermarket Potential: Building For Power

Both engines respond exceptionally well to modifications, but their different compression ratios create distinct upgrade paths:

Naturally Aspirated Builds

The LQ9’s higher compression (10.0-10.4:1) gives it a natural advantage for NA builds. With a 220° duration camshaft, you can expect 75+ hp gains. Add CNC-ported LS3 heads, and you’re looking at 550 hp territory.

The LQ4 can follow the same path, but its lower compression means slightly less NA potential unless you switch to flat-top pistons.

Forced Induction Builds

Here’s where the LQ4 has an edge. Its lower 9.4:1 compression ratio handles boost better, safely taking 12-15 psi on pump gas. The LQ9 typically needs to be limited to 8-10 psi on pump gas or requires lower compression pistons for serious boost.

This table summarizes the upgrade potential:

| Modification Type | LQ4 Advantage | LQ9 Advantage |

|---|---|---|

| Naturally Aspirated | Lower cost | Higher base compression |

| Forced Induction | Better with boost | Requires decompression |

| Camshaft Upgrade | Good gains | Excellent gains |

| Head Porting | Good flow | Good flow |

| Ease of Finding | More common | Less common, premium |

Cost and Availability: What You’ll Pay

The market values these engines differently based on their performance and rarity:

LQ4 Market Value:

- Used engines: $800-1,500

- More plentiful in junkyards

- Lower demand means better deals

LQ9 Market Value:

- Used engines: $1,200-2,000

- Harder to find in salvage

- Premium price reflects performance edge

If budget is a major concern, the LQ4 represents a better value, especially if you plan to modify the engine significantly. The price gap narrows when you factor in the cost of upgrading an LQ4 to match LQ9 specs.

For those seeking a crate engine solution, options like the ATK HP109 use LQ4 blocks with LS3 heads to create 505 hp packages starting at $5,199 – showing how far these platforms can be pushed.

Real-World Reliability: The Long Haul

Both engines have proven remarkably durable in stock form, regularly exceeding 200,000 miles with basic maintenance. Their iron blocks resist cylinder wall distortion under heat and pressure better than aluminum blocks, which is why many builders prefer them for high-horsepower applications.

The LQ4’s slightly lower compression can translate to less internal stress over time, but the difference is minimal in stock applications. Both engines use:

- Nodular iron crankshafts

- Powdered metal connecting rods

- Hypereutectic pistons

- Roller camshafts with 100,000+ mile lifespans

For reliability with modifications, the rule of thumb is simple: the LQ4 handles boost better, while the LQ9 responds better to naturally aspirated upgrades.

Making Your Choice: LQ4 or LQ9?

After weighing all factors, here’s how to decide:

Choose the LQ4 if:

- You’re on a tighter budget

- You plan to add forced induction

- You prioritize towing capacity

- You want a more common, easier-to-find engine

Choose the LQ9 if:

- You want more naturally aspirated power

- You prefer premium performance out of the box

- You’re building a high-RPM street engine

- You don’t mind paying more for better specs

For many builders, the LQ4 represents the better value proposition, especially considering the cost difference can be invested in performance upgrades that exceed stock LQ9 capabilities.

Upgrades That Work For Both

Whichever engine you choose, these modifications deliver substantial performance gains:

-

Headers and Exhaust: Both engines respond well to long-tube headers and 3-inch exhaust systems for 15-25 hp gains.

-

Cold Air Intake: A proper cold air intake system adds 10-15 hp to either engine.

-

ECU Tuning: A professional tune unlocks hidden potential, especially when paired with other modifications.

-

LS3 Rectangular Port Heads: These flow significantly better than the cathedral port heads on stock LQ4/LQ9 engines.

-

Roller Rocker Arms: Upgrading to 1.8:1 or 1.9:1 ratios increases valve lift without changing the camshaft.

The beauty of the LS engine family is the vast parts interchangeability, making either engine an excellent foundation for builds ranging from mild to wild.

Advanced Engine Specifications

For those who need precise measurements for building purposes:

| Parameter | LQ4/LQ9 Specification |

|---|---|

| Bore | 101.618-101.636 mm (4.0007-4.0014 in) |

| Stroke | 92.0 mm (3.622 in) |

| Main Bearing Diameter | 69.871-69.889 mm (2.75-2.751 in) |

| Oil Capacity | 5.68 liters (6 quarts) |

| Oil Pump Pressure | 41 kPa @ 1,000 RPM / 165 kPa @ 4,000 RPM |

| Firing Order | 1-8-7-2-6-5-4-3 |

With either the LQ4 or LQ9, you’re getting a robust, time-tested platform that responds exceptionally well to modifications. The choice ultimately comes down to your specific goals, budget constraints, and how you plan to use the engine.

Whether you’re building a street bruiser, a track monster, or a towing beast, these 6.0L powerplants deliver the grunt you need with classic LS reliability.