Your Chevy just slipped out of gear at a stoplight. Or maybe you’re dealing with that infamous harsh shift that rattles your teeth. If you’re driving a GM truck or SUV from the ’90s or 2000s, chances are you’ve got a 4L60E transmission—and it’s trying to tell you something.

What Makes the 4L60E So Problem-Prone?

The 4L60E isn’t a bad transmission. It’s just got a few critical weak spots that GM never really fixed. Think of it like a house with great bones but terrible plumbing—everything works fine until it doesn’t.

GM installed these transmissions in nearly every rear-wheel-drive vehicle from 1993 to 2013. Silverados, Sierras, Tahoes, Suburbans, Camaros, and even Corvettes got them. That’s millions of units out there, and they all share the same predictable failure points.

The “E” stands for electronic control. Unlike older transmissions that used cables and hydraulic governors, the 4L60E relies on solenoids and your truck’s computer to shift gears. When these systems fail, you’ll know immediately.

The 3-4 Clutch Burnout: The Most Common Killer

Here’s the big one. If your truck has Reverse, 1st, and 2nd gear but slips or goes into neutral in 3rd and 4th, you’ve got burnt 3-4 clutches. This isn’t just wear and tear—it’s a design flaw.

The 3-4 clutch circuit is stupidly long. Fluid has to travel from the pump, through multiple valves, into the input shaft, and finally into the drum to apply pressure. Any leak along this path means the clutches slip, generate heat, and die.

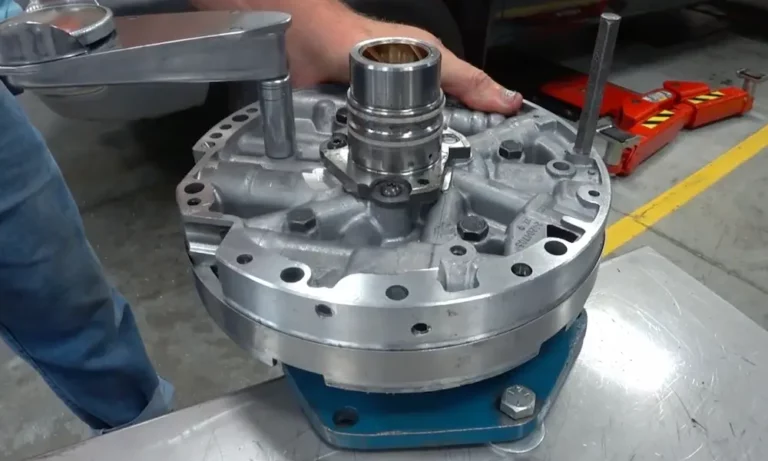

Why the Input Housing Fails

The input housing is where things get messy. It’s an aluminum part with a steel shaft pressed into it. Over time, the steel galls (scratches) the aluminum bore. Once that happens, the housing can’t hold pressure anymore.

There’s also a checkball capsule inside that’s supposed to vent air. If it leaks, centrifugal force literally throws your transmission fluid out of the circuit while the shaft spins. Your clutches get starved of pressure and burn up in minutes.

The Teflon sealing rings on the input shaft wear out too. When they fail, fluid bypasses into other circuits instead of applying the 3-4 pack. You’ll never know it’s happening until you’re stuck on the side of the road.

The Backing Plate Problem

The stock 3-4 backing plate is too thin. Under load—especially if you’re towing—it flexes like a drumhead. This creates uneven clamping force across the clutch pack. Some spots overheat and glaze while others barely touch. The whole pack fails as a unit.

Upgraded rebuild kits use thicker heat-treated backing plates to prevent this flexing. It’s a cheap fix that should’ve been factory spec from day one.

The Broken Sun Shell: No Reverse, 2nd, or 4th Gear

This one’s dramatic. You’re driving along fine, then suddenly you’ve got no Reverse, no 2nd gear, and no 4th gear. But 1st and 3rd still work? That’s a sheared sun shell.

The reaction sun shell is a stamped steel bowl that transfers torque to the planetary gears. GM made it out of cheap material with a splined neck that can’t handle the stress of heavy acceleration or harsh shifts. The neck literally snaps off.

You might hear a grinding or ticking noise before it breaks. That’s the splines stripping or the shell rattling around inside the case. Once it goes, you’re done.

The fix is called “The Beast” or the Sonnax Smart Shell. It’s a hardened, reinforced shell that actually handles V8 torque and towing loads. Every serious rebuild uses one.

The P1870 Code: Why Your 1-2 Shift Feels Like a Car Crash

If your truck slams into 2nd gear like it got rear-ended, you probably have code P1870 stored in the computer. This code means “Transmission Component Slipping,” but it’s not what you think.

What’s Actually Happening

The torque converter clutch (TCC) is supposed to lock smoothly using pulse width modulation. The valve that controls this oscillates rapidly in its bore—thousands of times per day, for years. Eventually, it wears the aluminum bore out.

Once the bore is worn, hydraulic pressure leaks past the valve. The converter clutch slips. Your truck’s computer detects the slip between engine RPM and transmission input speed.

Here’s the sneaky part: the computer’s response to this slip is to command maximum line pressure to all the clutches. It’s trying to prevent further damage. But max line pressure makes the 1-2 shift violent enough to break other parts.

The Harsh Shift Is a Warning, Not the Problem

Don’t ignore that harsh shift. It means your transmission is operating in limp-protect mode. The underlying issue is the worn TCC regulator bore, and it’ll only get worse.

You’ve got two fix options. The pro way is to ream the bore oversized and install a Sonnax sleeve kit. The budget way is a “Fitzall” drop-in valve that uses O-rings to seal against unworn sections of the bore. Both work, but the Sonnax fix lasts longer.

No Reverse: A Specific Diagnosis Path

Lost Reverse? Don’t panic yet. Check your other gears first.

If you’ve also lost 2nd and 4th gear, it’s the sun shell. We covered that above.

If forward gears work fine, you’ve got a different problem. Low fluid affects Reverse first because that circuit needs high volume and pressure. Top off your fluid and see if it comes back.

Still nothing? The Lo-Reverse clutches in the rear of the case are worn out. This is common in high-mileage transmissions. The reverse input drum can also “dish” (warp), preventing full clutch apply.

Here’s a table breaking down the diagnosis:

| What’s Working | What’s Missing | Likely Cause | Action Required |

|---|---|---|---|

| 1st, 3rd | Reverse, 2nd, 4th | Broken sun shell | Full rebuild with Beast shell |

| All forward gears | Reverse only | Low fluid or Lo-Rev clutches | Check fluid, rebuild if burnt |

| Reverse only | All forward gears | Forward sprag failure | Full rebuild (major failure) |

| Nothing | Nothing | Pump failure or no line pressure | Full rebuild or replacement |

Solenoid Failures: The Electronic Headaches

The 4L60E uses multiple solenoids to control shifts. When they fail, you get weird symptoms that don’t match mechanical problems.

The 3rd Gear Limp Mode

If your truck takes off from a stop like it’s towing a house, it’s starting in 3rd gear. This is “limp mode”—the computer’s default when it loses electrical connection to the transmission.

Both shift solenoids are normally open. When they lose power, the transmission defaults to 3rd gear for safety. You can still drive, but acceleration is terrible.

Check the “TRANS” or “CLSTR” fuse first. It’s usually a 10-amp fuse that powers all the solenoids. If it’s blown, that’s your problem. If the fuse is good, you’ve got a wiring issue or failed solenoid.

The 1996 Solenoid Change You Need to Know

Here’s a critical detail: GM changed the 3-2 downshift solenoid resistance in 1996. Early transmissions (1993-95) used a 9-14 ohm solenoid. Later units (1996+) use a 20-31 ohm solenoid.

If you mix them up, you’ll damage your PCM or throw immediate codes. Always verify the resistance with a multimeter before installing solenoids in a 4L60E rebuild.

The internal wiring harness also fails. It sits in hot transmission fluid for years until the insulation cracks. Wires short to the case, causing random solenoid codes or the TCC locking up at stoplights and stalling your engine.

Torque Converter Shudder: The Washboard Effect

You’re cruising at 45 mph when it feels like you’re driving over rumble strips. That’s TCC shudder, and it’s annoying as hell.

The torque converter clutch inside the converter is either glazed or the friction material is worn. When it tries to lock, it grabs, slips, grabs, slips—creating that vibration.

The Brake Tap Test

Here’s how you confirm it’s the TCC and not an engine misfire: while the shudder is happening, lightly tap your brake pedal. Just enough to light the brake lights, not enough to slow down.

If the shudder stops immediately, it’s the TCC. The brake signal tells the computer to unlock the converter. If the vibration continues, you’ve got an engine misfire or bad motor mount.

Fresh fluid with friction modifiers sometimes helps. But if the converter clutch material is glazed, you need a new converter. Expect to pay $600-$1,000 for replacement including labor.

Heat: The Silent Killer

Most 4L60E problems start with heat. The factory cooling setup routes fluid through your radiator’s end tank. It’s barely adequate for normal driving and totally insufficient for towing.

Once transmission fluid hits 220°F, it starts breaking down. Seals harden, clutch material degrades, and metal parts expand beyond spec. At 240°F, you’re cooking the transmission alive.

The Tru-Cool 40K Upgrade

The Tru-Cool 40K transmission cooler is the gold standard for GMT800 trucks (1999-2007 Silverado/Sierra). It’s rated for 40,000 GVW and 45,000 BTUs.

Installing one can drop your fluid temps by 40-50 degrees. Keeping fluid under 175°F basically doubles transmission life compared to running at 220°F. It’s a $200 part that saves you a $2,500 rebuild.

Should You Rebuild or Replace?

This is the big money question. Here’s the reality check:

Used/Junkyard ($500-$800): You’re buying someone else’s problem. These transmissions have the same weak points as yours. Even with a 90-day warranty, it’s a gamble.

DIY Rebuild ($600-$1,500): Parts kits run $200-$500, plus you need a torque converter ($150+), solenoids ($100+), and possibly hard parts like a sun shell or input drum. You also need specialized tools and knowledge. Screw it up and you’ve wasted everything.

Shop Rebuild ($1,800-$2,800): Quality varies wildly. Make sure the shop addresses the valve body wear (P1870 fix), installs a hardened sun shell, and uses quality clutches. A cheap “soft parts only” rebuild will fail again in a year.

Remanufactured ($2,000-$3,000 + labor): Companies like Jasper or Monster Transmission provide units with upgraded hard parts, sleeved valve bodies, and 3-year/100k warranties. Add $800-$1,200 for installation. It’s the most expensive option but the safest bet.

| Repair Type | Total Cost | Warranty | Reliability Risk |

|---|---|---|---|

| DIY Rebuild | $600-$1,500 | None | High (mistakes costly) |

| Used Transmission | $1,000-$1,600 | 30-90 days | Very high (unknown history) |

| Local Shop Rebuild | $1,800-$2,800 | 1 year/12k | Moderate (shop-dependent) |

| Remanufactured Unit | $3,000-$4,200 | 3 year/100k | Low (factory upgrades) |

The Corvette Servo Upgrade

If you’re rebuilding or having your transmission rebuilt, insist on the Corvette servo upgrade. It’s a $30 part that makes a huge difference.

The servo is a piston that applies the 2-4 band. The Corvette version has a larger surface area, which means more apply force. This firms up the 1-2 and 2-3 shifts, reduces slippage, and cuts heat generation during shifts.

It’s the single best bang-for-buck modification you can do to a 4L60E. Every performance builder uses them.

Recognizing Year-Specific Differences

Not all 4L60E transmissions are the same. There are four distinct generations, and they’re not electrically compatible with each other.

1993-1995: 12-pin connector. Non-PWM TCC logic in early years. 1995 is a “bastard year” with unique solenoids. Avoid these for swaps.

1996-2006: 13-pin connector. This is the “standard” 4L60E. Bolt-on bellhousing started in 1996. Most common and best for parts availability.

2007-2008: 15-pin connector. Added input speed sensor. Requires specific wiring harness.

2009+: 17-pin connector. Fully CAN-bus integrated with internal mode switch. Won’t work in older trucks without serious wiring modifications.

If you’re swapping or replacing, stick with the same generation. A 2005 transmission won’t work in a 1994 truck without rewiring the entire system.

Preventive Maintenance That Actually Works

You can extend your 4L60E’s life with three simple steps:

1. Fluid changes every 30,000 miles. Use Dexron VI (or Dexron III if pre-2006). Don’t believe the “lifetime fluid” myth. Change it.

2. Install a quality transmission cooler. The Tru-Cool 40K is overkill for daily driving, but overkill is good here. Keep that fluid cool.

3. Fix the P1870 code immediately. That harsh shift is destroying your sun shell and planetary gears. A $150 valve fix now prevents a $2,500 rebuild later.

Stop towing heavy loads without a transmission cooler. Stop ignoring harsh shifts. Stop putting off fluid changes. These three things kill more 4L60E transmissions than anything else.

The Bottom Line on 4L60E Transmission Problems

The 4L60E gets a bad rap, but it’s not a terrible transmission—it’s just got specific weak points that GM never addressed. The 3-4 clutch circuit leaks. The sun shell breaks. The TCC regulator bore wears out. These are predictable, fixable problems.

If you catch issues early (like P1870 codes or minor slipping), repairs are relatively cheap. Wait until you’re stuck in limp mode or have no Reverse, and you’re looking at a full rebuild.

When you do rebuild, don’t cheap out. Use the hardened sun shell, fix the valve body properly, upgrade the servo, and install a serious transmission cooler. Do it right once instead of halfway three times.

Your 4L60E can handle 300,000+ miles if you treat it right. Just don’t expect it to survive neglect and heavy towing on factory specs. Upgrade the weak points, keep it cool, and change the fluid. That’s the formula.