When dealing with 4L80E transmission problems, knowing the common issues and their fixes can save you time and money. You might experience erratic shifting or excessive wear in certain parts. These problems are often linked to faulty sensors or electronic controls and might need a rebuild kit. By understanding these issues, you can tackle them efficiently and keep your vehicle running smoothly. Dive in to learn how to address these challenges effectively.

Common Mechanical Failures

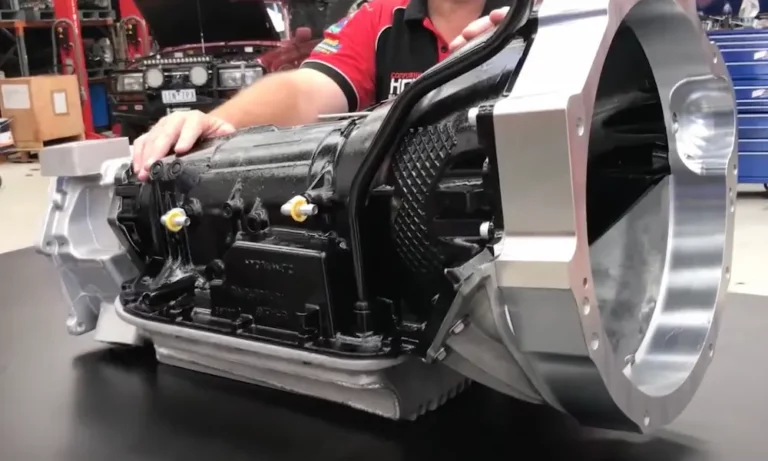

Dealing with the 4L80E transmission can involve several mechanical challenges. You might face issues related to the torque converter, solenoids, valve body, and others. It’s important to understand these potential problems to maintain the longevity and performance of your transmission.

Torque Converter Issues

The torque converter plays a crucial role in automatic transmissions. A common problem is when it fails to lock up properly. This can result in slipping, where the engine speed increases without a corresponding increase in vehicle speed. A slipping torque converter can cause overheating and poor fuel efficiency.

If you notice shuddering or unusual vibrations, it might be time to inspect the torque converter. Use quality transmission fluid and maintain proper levels to avoid these problems. Torque Converter Not Locking Up can lead to more significant issues if not addressed promptly.

Solenoid and Valve Body Problems

The valve body is like the brain of your transmission. It directs hydraulic fluid to various components to control gear shifting. Problems with the solenoids, which are small electrically controlled valves, can cause erratic shifting or failure to shift.

Sometimes, loose or corroded wiring connections can affect solenoid performance. It’s crucial to ensure all electrical connections are secure and free from corrosion. The design of the valve body, aimed at cost-effectiveness, may not always offer superior longevity. Making sure you have good solenoid and valve body maintenance can help prevent performance problems.

Clutch, Band, and Gear Failures

Clutches and bands are vital for smooth gear operation. The 4L80E transmission can experience wear in these areas leading to slipping or harsh gear changes. The direct clutch is one area that commonly wears out over time.

You may notice delayed shifts or slippage, indicating problems with the clutch or bands. Regular maintenance and timely fluid changes can help prevent excessive wear. If you suspect a problem, have it checked to prevent more serious damage.

Fluid Leaks and Seal Degradation

Fluid leaks are another common issue with the 4L80E transmission. Leaks can occur around the separator plate, gaskets, or seals. When transmission fluid is low due to leaks, it can lead to overheating and inefficient operation.

Look for spots of red or brown fluid under your vehicle, which are signs of leaks. Regularly inspecting the seals and replacing any degraded ones can prevent leaks. Keeping the transmission fluid at the recommended level is crucial for optimal performance. Seal degradation can lead to costly repairs if not handled early.

Electrical Component Concerns

The 4L80E transmission relies heavily on electronic components, making any electrical issues critical to address. Understanding these components and their problems can help prevent erratic shifting and ensure smooth operation.

Sensors and Wiring Issues

Problems with sensors often lead to shifting troubles. Throttle position sensors can affect how your transmission shifts by sending incorrect throttle data to the TCM. This may cause improper gear changes.

Another important sensor is the input speed sensor. It monitors the rotational speed of the input shaft. If it fails, the PCM may receive incorrect information, causing gear shift issues. Similarly, a bad vehicle speed sensor can lead to erratic speedometer readings or affect the operation of the cruise control.

Wiring issues are a common culprit and can occur due to damaged or corroded wires. These issues can disrupt signals from shift solenoids, TCC solenoids, or any sensor, leading to poor transmission performance. It’s also important to regularly check the electrical connectors to ensure they are secure and free of debris.

Transmission Control Module (TCM) Problems

The Transmission Control Module (TCM) is like the brain of your transmission. It processes data from all the sensors to manage shifting. If the TCM encounters issues, you might experience hard shifts or the transmission may fail to shift at all.

A common cause of TCM problems is faulty connections or damaged wiring. This can affect the way it sends signals to shift solenoids or reads sensor data. Ensuring that the TCM receives the right input from line pressure sensors or the output shaft sensor is vital for maintaining proper operation.

Sometimes, reprogramming or resetting the TCM can fix the issue. More severe cases might require a replacement. Pay attention to any warning lights or error codes from your vehicle, as these can provide clues about TCM problems.

Transmission Fluid Management

Managing your 4L80E transmission fluid is essential for smooth operation and longevity. Ensuring proper fluid condition and avoiding overheating are key aspects to keep in mind.

Fluid Condition and Service Intervals

Regularly checking your transmission fluid is crucial. Look for signs of wear, like dark color or burnt smell. If you notice any of these, it’s time for a change. Keeping fluid clean and at the right level helps maintain fluid pressure, which is vital for shifting gears smoothly.

It’s important to follow the recommended service intervals for changing the fluid. Typically, this is every 30,000 to 50,000 miles. Consistent maintenance not only enhances performance but also extends the transmission’s life. Checking the dipstick regularly can help you stay on top of fluid levels.

Effects of Overheating on Fluid

Overheating is a major issue for transmission fluid. High temperatures can cause the fluid to break down, reducing its effectiveness in lubricating and protecting the transmission. To prevent overheating, ensure your transmission cooling system is in good condition.

Overheated fluid loses its ability to maintain proper fluid pressure, leading to poor gear shifts and potential damage. Avoid heavy towing or harsh driving conditions for long periods, as these can increase heat. Keeping your transmission fluid at a stable temperature is critical to prevent costly repairs and ensure reliable operation. Regular inspections and preventative measures can save you from headaches down the road.

Specific Issues by Model

Understanding the issues with the 4L80E transmission can help keep your vehicle running smoothly. Whether you drive a Chevrolet Silverado, GMC Sierra, or a high-performance car, knowing what problems might arise is key.

Chevrolet Silverado and GMC Sierra Concerns

If you own a Chevrolet Silverado or GMC Sierra, you might encounter some problems with the 4L80E transmission. A common issue is delayed shifting into 4th gear. This can happen if there’s a fault in the transmission solenoid. The 4L80E Troubleshooting Guide suggests checking the solenoids and the wiring connections.

Another problem is rough shifting. The transmission might feel jerky due to worn-out components or low transmission fluid. Regular maintenance, including changing the transmission fluid and filter, can prevent these issues. Regular checks ensure the shifter operates smoothly, which is vital for your heavy-duty automatic transmission.

4L80E in High-Performance and Luxury Vehicles

High-performance and luxury vehicles, including some models of Aston Martin, use the 4L80E transmission. These vehicles experience different stresses than trucks due to their power output. The transmission might struggle with heat build-up under heavy use, leading to overheating issues.

To address these, installing a high-performance transmission cooler can be beneficial. Ensuring proper tuning of the transmission control unit is crucial. This can help avoid problems with shifting and extend the life of your transmission. If you’re interested in upgrades, performance shops offer custom parts that can increase durability and performance, enhancing your driving experience.

Maintenance Tips for Longevity

Regular maintenance is key to keeping your 4L80E transmission running smoothly. Make it a habit to check the transmission fluid levels. Use the dipstick to ensure it’s at the right level. Also, inspect the color and smell of the fluid. If it looks dark or smells burnt, consider changing it.

Fluid changes are not just about levels. Over time, transmission fluid can break down and lose its effectiveness. Replace old fluid with the recommended type to keep your transmission running efficiently. For the 4L80E, using Dexron VI is a good choice.

Don’t forget about your torque converter. This part plays a big role in how your transmission works. If you notice any shuddering or slipping, it might be time to check on the torque converter and possibly replace it.

Bands and clutches are crucial components, too. If your transmission feels like it’s slipping or if shifts are rough, these might need adjustment or even replacement. Keeping these parts in good condition helps avoid bigger issues down the road.

Regularly scheduled maintenance can prevent costly repairs in the future. Make sure you address small problems before they become bigger ones. By staying on top of these tasks, you’re doing your part to ensure the longevity of your 4L80E transmission.