Looking to understand what makes the Dodge 318 engine tick? Whether you’re restoring a classic Mopar, troubleshooting issues, or just appreciating this legendary powerplant’s history, you’ve found the right resource. This guide covers everything from performance specs to maintenance tips for one of America’s most enduring V8 engines.

The Evolution of the Dodge 318 Engine

The 318 cubic inch V8 engine (5.2 liters) became one of Chrysler Corporation’s most successful powerplants, with a production run spanning more than four decades. This remarkable longevity speaks volumes about the engine’s fundamental design strength and adaptability.

The 318’s journey began in 1957 when Chrysler introduced it for Plymouth vehicles, most notably in the 1957 Plymouth Fury. In these early applications, the high-performance version with dual four-barrel carburetors generated an impressive 290 horsepower – quite remarkable for its time. The engine didn’t join the Dodge lineup until late 1959 for the 1960 model year, starting its long association with the brand.

From its introduction until its final production in 2003 as the Magnum variant, the 318 underwent several significant revisions while maintaining its core architecture. This engine powered countless vehicles across Chrysler’s brands, becoming known for its exceptional balance of power, reliability, and versatility.

Basic 318 Engine Specifications

The Dodge 318 maintained consistent fundamental dimensions throughout its production run:

| Specification | Measurement |

|---|---|

| Displacement | 318 cubic inches (5.2 liters) |

| Cylinder Bore | 3.91 inches (99.3 mm) |

| Piston Stroke | 3.31 inches (84.0 mm) |

| Block Material | Cast iron |

| Head Material | Cast iron |

| Valve Configuration | OHV (overhead valve) |

| Valves Per Cylinder | 2 (16 valves total) |

| Firing Order | 1-8-4-3-6-5-7-2 |

The engine featured a 90° V configuration with a single camshaft and a robust five-bearing crankshaft support system that contributed significantly to its legendary durability across all applications.

Performance Variations Through the Years

The 318’s performance characteristics evolved significantly throughout its production history, adapting to changing automotive needs and emissions requirements.

Early Performance (1957-1962)

When first introduced, the 318 was positioned as a performance engine, with various carburetor configurations delivering different power levels:

- 1957 high-performance (dual four-barrel): 290 HP @ 5,400 rpm, 325 lb-ft @ 4,000 rpm

- 1958 standard (two-barrel): 225 HP @ 4,400 rpm, 330 lb-ft @ 2,800 rpm

- 1958 enhanced (four-barrel): 250 HP @ 4,400 rpm, 340 lb-ft @ 4,000 rpm

- 1958 Fury (dual four-barrel): 290 HP @ 5,400 rpm, 330 lb-ft @ 3,600 rpm

Middle Years (1959-1971)

During this period, the 318 settled into more mainstream applications:

- Standard two-barrel: 230 HP @ 4,400 rpm, 340 lb-ft @ 2,400 rpm

- Four-barrel option: 260 HP @ 4,400 rpm, 345 lb-ft @ 4,000 rpm (except 1960: 255 HP)

Magnum Era (1992-2003)

The final evolution of the 318 came with the Magnum variant, featuring fuel injection rather than carburetors:

- Power output: 230 HP @ 4,100 rpm

- Maximum torque: 295 lb-ft @ 3,000 rpm

Though the peak horsepower was lower than the earliest high-performance versions, the Magnum offered better drivability, improved fuel efficiency, and superior reliability while meeting modern emissions standards.

Technical Design Features

The 318’s impressive longevity stems from several key design elements that made it both reliable and adaptable to changing automotive requirements.

Block and Cylinder Head Design

The engine used a cast iron block paired with cast iron heads in a single overhead valve (OHV) configuration. This robust construction contributed significantly to the engine’s legendary durability. The cylinder heads featured two valves per cylinder (one intake, one exhaust) for a total of 16 valves.

In its Magnum iteration, the 318 utilized:

- Aluminum alloy pistons with two compression rings and one oil control ring

- Forged steel connecting rods

- Nodular iron crankshaft with 2.5-inch main journal diameter and 2.08-inch crankpin diameter

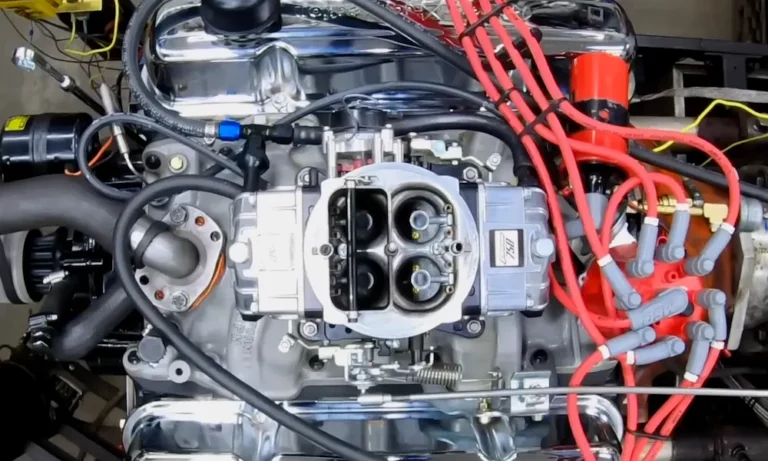

Fuel System Evolution

The 318’s fuel delivery systems evolved dramatically over its production life:

- Early models (1957-1960s): Various carburetor configurations including:

- Single two-barrel carburetors (standard models)

- Single four-barrel carburetors (enhanced performance)

- Dual four-barrel carburetors (high-performance applications)

- Later LA-series models: Primarily two-barrel and four-barrel carburetors with emissions control equipment added as regulations evolved.

- Magnum era (1992-2003): Multi-point fuel injection system with electronically controlled timing, providing improved fuel economy and emissions compliance.

This ability to adapt to changing fuel delivery technologies helped extend the 318’s production life well into the fuel-injected era.

The 318’s Reputation: Strengths and Weaknesses

The 318 earned a strong reputation for reliability and serviceability, but like all engines, it had its characteristic strengths and limitations.

Notable Strengths

- Exceptional Reliability: The 318 became known as one of the most dependable engines in Chrysler’s lineup, often running for hundreds of thousands of miles with basic maintenance.

- Thermal Efficiency: The design maintained good thermal characteristics, with even cooling across cylinders that prevented hot spots and warping issues common in some competitors.

- Serviceability: The straightforward design made maintenance relatively easy, with good access to key components.

- Adaptability: The 318 proved remarkably adaptable to changing emissions requirements and performance needs, which explains its exceptional production longevity.

Known Limitations

- Weight: The all-iron construction, while durable, created a relatively heavy engine compared to later designs incorporating aluminum components.

- Oil System: Early versions didn’t have the most robust oil system, making oil changes and proper maintenance particularly important.

- Power Density: Compared to some competing designs, the 318 wasn’t the most power-dense engine, though its torque characteristics were well-suited to American driving styles.

Essential Maintenance Specifications

Proper maintenance is critical for maximizing the longevity of any 318 engine. Here are the key specifications for maintenance and rebuilding:

Torque Specifications

Following the correct torque values ensures proper sealing and prevents mechanical failures:

| Component | Torque Specification |

|---|---|

| Main Cap Bolts | 85 ft-lbs |

| Connecting Rod Bolts (Plain) | 45 ft-lbs |

| Cylinder Head Bolts (273-318) | 85 ft-lbs (follow factory sequence) |

| Rocker Shaft Bracket Bolts | 17 ft-lbs |

| Intake Manifold Bolts | 35 ft-lbs |

| Oil Pump Cover Bolt | 95 inch-lbs |

| Oil Pump Attaching Bolt | 35 ft-lbs |

| Oil Pan Bolts | 15 ft-lbs |

| Cam Locking Bolt | 35 ft-lbs |

| Cam Thrust Plate Bolts | 210 inch-lbs |

| Harmonic Damper Bolt | 135 ft-lbs |

| Flywheel/Flexplate Bolts | 55 ft-lbs |

| Front Cover Bolts | 30 ft-lbs |

| Water Pump Bolts | 30 ft-lbs |

These specifications apply to stock-type bolts with light engine oil applied to threads and the bolt head underside. For performance applications using aftermarket fasteners, follow the manufacturer’s specific recommendations.

Fluid Capacities and Specifications

| Fluid Type | Capacity/Specification |

|---|---|

| Engine Oil | 5 quarts (with filter) |

| Recommended Oil Weight | 10W-30 (standard conditions) |

| Oil Pressure (hot at idle) | 15-20 PSI minimum |

| Oil Pressure (hot at 2500 RPM) | 45-60 PSI |

| Coolant Capacity | Varies by vehicle application |

Performance Modification Potential

The 318 responds well to performance upgrades, making it popular among enthusiasts looking to extract more power while maintaining reliability.

Exhaust System Upgrades

One of the most effective modifications for the 318 is upgrading the exhaust system. Stock exhaust manifolds, particularly in earlier models, were quite restrictive.

- Dodge Magnum Exhaust Manifolds: These provide a substantial improvement over original log-style manifolds while maintaining a stock appearance, offering a good balance of performance and practicality.

- Headers: Long-tube headers deliver the greatest performance gains throughout the RPM range. Dyno testing consistently shows that properly sized long tubes increase power across the entire power band.

- Exhaust Diameter: For single exhaust applications, at least a three-inch diameter pipe is recommended for adequate flow, though a true dual exhaust system typically provides the best overall performance.

- Catalytic Converters: When required by regulations, high-flow variants minimize performance losses while maintaining emissions compliance.

Intake and Carburetor Modifications

The intake path represents another restriction point in stock 318 engines:

- Intake Manifolds: Aluminum performance intakes offer better flow characteristics and lower weight than stock cast iron manifolds.

- Carburetor Upgrades: For carbureted models, replacing a two-barrel with a four-barrel carburetor and matching manifold provides substantial performance improvement.

- Electronic Fuel Injection: For late-model 318s or restomods, modern EFI systems offer improved drivability, fuel economy, and tuning potential.

Cylinder Head Improvements

The stock cylinder heads are often the most significant restriction in the 318’s breathing ability:

- Port Work: Even basic port matching and cleanup can yield noticeable gains.

- Valve Size Increases: Slightly larger valves improve flow without requiring extensive modification.

- Aftermarket Heads: Complete aftermarket cylinder heads provide the greatest potential with improved combustion chamber design, larger valves, and better port geometry.

The 318’s Cultural Impact

Beyond its technical merits, the 318 secured a place in American car culture through several notable appearances.

The engine powered the evil 1958 Plymouth Fury in the film adaptation of Stephen King’s “Christine,” cementing its association with classic American muscle. Additionally, television producers of “The Dukes of Hazzard” specifically selected 318-powered Dodge Chargers for their famous jump stunts because they were significantly lighter than vehicles with larger 440 or 383 engines, making them easier to balance during aerial maneuvers.

These cultural touchpoints helped establish the 318’s reputation beyond just automotive enthusiasts, making it one of the most recognizable American V8 engine configurations.

Common Applications of the 318 Engine

The 318’s versatility allowed it to power a wide range of vehicles throughout its production life:

Passenger Cars

- Dodge Charger

- Dodge Challenger

- Dodge Coronet

- Plymouth Barracuda

- Plymouth Fury

- Plymouth Road Runner

- Chrysler Cordoba

- Chrysler New Yorker

Trucks and Vans

- Dodge Ram

- Dodge Dakota

- Dodge Ram Van

- Plymouth Voyager

Commercial/Fleet Vehicles

- Dodge B-series vans

- Various police and fleet applications

This incredible range of applications demonstrates the 318’s adaptability and reliability across multiple vehicle types and use cases.

Identifying a Dodge 318 Engine

If you’re trying to confirm whether an engine is indeed a 318, here are key identification points:

Block Casting Numbers

Casting numbers are typically found on the left side of the block near the distributor. The specific numbers vary by year and production facility, but they’re the most definitive way to identify the engine.

Visual Clues

- The 318 has a slightly smaller exterior size compared to the 360 and larger Mopar engines

- The intake manifold will have certain characteristics specific to the displacement

- For Magnum variants, look for the distinctive Magnum heads with center bolt valve covers

Decoding VIN and Fender Tag

For vehicles with their original engines, the VIN and fender tag information can confirm the factory-installed engine displacement.

Comparing the 318 to Other Mopar V8s

To understand the 318’s place in the Mopar lineup, it helps to compare it to its siblings:

| Engine | Displacement | Years Produced | Key Characteristics |

|---|---|---|---|

| 273 V8 | 273 cu in (4.5L) | 1964-1969 | Smaller predecessor to the 318, similar architecture |

| 318 V8 | 318 cu in (5.2L) | 1957-2003 | The focus of this article, balanced performance and reliability |

| 340 V8 | 340 cu in (5.6L) | 1968-1973 | Performance-focused version with better breathing |

| 360 V8 | 360 cu in (5.9L) | 1971-2003 | Larger displacement variant of the LA series, more torque |

| 383 V8 | 383 cu in (6.3L) | 1959-1971 | B-series engine, significantly larger than the 318 |

| 440 V8 | 440 cu in (7.2L) | 1966-1978 | Largest Mopar production V8, maximum torque and power |

The 318 occupied the sweet spot of adequate power, excellent reliability, and reasonable fuel economy compared to both smaller and larger offerings in the Mopar engine family.

The Legacy of the Dodge 318

Few engines can claim a production run spanning nearly half a century, but the 318 accomplished exactly that. From its introduction in 1957 to its final year in 2003, this versatile V8 evolved from a carbureted high-performance engine to a fuel-injected, emissions-compliant powerplant while maintaining its reputation for reliability.

Today, the 318 remains popular among enthusiasts for restoration projects and performance builds. Its combination of reasonable power potential, excellent parts availability, and legendary durability makes it an outstanding choice for classic car owners who want a dependable powerplant with good upgrade potential.

For those considering a Mopar project vehicle, a 318-powered option provides the perfect balance of authentic vintage character and real-world usability – a fitting legacy for one of America’s most enduring V8 engines.