Ever wondered what makes the Ford 460 engine such a legendary powerhouse? This massive 7.5-liter V8 dominated Ford’s lineup for three decades, powering everything from luxury Lincolns to heavy-duty trucks. Whether you’re restoring a classic, building a hot rod, or just appreciating automotive history, understanding this iconic big block can help you appreciate why it remains so popular today.

What Is the Ford 460 Engine?

The Ford 460 stands as the largest displacement production engine Ford ever made. Part of Ford’s “385” engine family (which included the 429 cubic inch variant), this big block V8 began production in 1968 at Ford’s Lima, Ohio plant and continued until 1998 – an impressive 30-year run that speaks to its versatility and reliability.

This wasn’t just any engine – it was a torque monster designed when fuel economy took a backseat to raw power and performance. With a massive 460 cubic inches (7.5 liters) of displacement, it delivered the grunt needed for everything from luxury cars to work trucks.

Core Ford 460 Engine Specifications

Let’s break down the fundamental specs that define this legendary powerplant:

| Specification | Details |

|---|---|

| Configuration | V8 with 90° bank angle |

| Displacement | 460 cubic inches (7.5 liters) |

| Bore | 4.36 inches (110.8 mm) |

| Stroke | 3.85 inches (97.8 mm) |

| Rod Length | 6.605 inches (standard) |

| Valvetrain | Overhead valve (OHV), 2 valves per cylinder |

| Block Material | Cast iron |

| Head Material | Cast iron (standard) |

| Firing Order | 1-5-4-2-6-3-7-8 |

The 460’s architecture followed classic American V8 design principles, with its overhead valve setup and cast iron construction providing excellent durability. While sharing the same 4.36-inch bore as the 429, the 460’s longer 3.85-inch stroke gave it the displacement boost that made it the big block king in Ford’s lineup.

Evolution of Power and Performance

The 460’s output varied dramatically throughout its production run, reflecting changing emissions regulations and the transition to unleaded fuel.

Early Years (1968-1972): The Golden Era

The early 460 engines were true powerhouses:

- 365 horsepower at 4,400 RPM

- 485 lb-ft of torque at 2,800 RPM

- 10.5:1 compression ratio

These high-compression engines delivered impressive performance, particularly in luxury applications where smooth, effortless power was the priority.

Mid-Production (1972-1987): The Emissions Era

The introduction of stricter emissions standards and the shift to unleaded fuel forced significant changes:

- Power dropped to 212 horsepower

- Torque decreased to 342 lb-ft

- Compression ratio reduced to 8.5:1

It’s important to note that this dramatic power reduction wasn’t solely due to performance degradation. The industry also shifted from optimistic “gross” horsepower ratings to more realistic “net” measurements during this period, accounting for some of the statistical decline.

Later Years (1988-1998): The Fuel Injection Era

The introduction of electronic fuel injection helped restore some performance:

- 245 horsepower

- 400 lb-ft of torque

- Improved drivability and efficiency

These fuel-injected models maintained this output until production ended, making them particularly desirable for many enthusiasts looking for stock power with modern drivability.

Fuel System Development

The 460’s fuel delivery systems evolved significantly throughout its production run:

Carburetion Era (1968-1987)

Early 460s utilized various carburetor setups:

- Primarily 4-barrel designs

- Holley and Motorcraft carburetors common

- Various sizes depending on application and model year

Carbureted 460s deliver that classic big-block sound and feel, but they’re more maintenance-intensive and less efficient than their later fuel-injected counterparts.

Fuel Injection Era (1988-1998)

The transition to multi-port electronic fuel injection in 1988 brought several advantages:

- Improved cold starting

- Better fuel economy

- More consistent performance

- Enhanced throttle response

- Fewer maintenance requirements

This technological update helped the 460 remain viable in an era of increasing efficiency demands, particularly in truck applications where its torque was still highly valuable.

Cylinder Head Design and Evolution

The cylinder heads on the 460 have always been a point of discussion among enthusiasts, with some notable strengths and weaknesses:

OEM Head Characteristics

Factory 460 heads featured:

- Oval-shaped intake ports that promoted excellent torque production

- Restrictive exhaust ports that limited high-RPM breathing

- 2.19-inch intake valves and 1.76-inch exhaust valves on early models

Among factory options, the 1969 “C9VE” and 1970 “DOVE” castings are considered the most desirable for performance builds. The 1972 heads developed a poor reputation due to quench area design issues, which Ford corrected in the 1973 models.

Modern Aftermarket Options

Today’s builder has numerous head options that overcome the limitations of stock castings:

- Aluminum heads reduce weight (up to 40 pounds per pair)

- Improved port designs enhance flow

- Larger valves increase breathing capacity

- Better combustion chamber designs improve efficiency

Aftermarket heads are often the single most effective upgrade for a 460 build, commonly delivering 50+ horsepower gains over stock heads.

Performance Potential and Modern Builds

Despite being designed in the 1960s, the 460 platform has tremendous potential with modern components and building techniques.

Compression Recommendations

For those building a performance 460, compression ratio recommendations vary by head material and fuel type:

- Iron heads: 9.0:1 for regular unleaded, 9.5:1 for premium

- Aluminum heads: 9.5:1 for regular unleaded, 10.0:1 for premium fuel

Aluminum heads dissipate heat more efficiently, allowing slightly higher compression ratios without detonation issues.

The Ford Performance Z460

Ford Performance offers an impressive modern crate engine version of the 460:

| Z460 Specification | Value |

|---|---|

| Horsepower | 575 HP at 5,500 RPM |

| Torque | 575 lb-ft at 4,700 RPM |

| Block | Boss 351 9.5″ deck height |

| Compression Ratio | 10.0:1 |

| Connecting Rods | H-beam |

| Cylinder Heads | Aluminum “Z” heads |

| Valve Sizes | 2.02″ intake, 1.60″ exhaust |

| Maximum RPM | 5,600 RPM |

This modern interpretation shows what’s possible with the 460 architecture when built with contemporary components – over 200 horsepower more than the factory ever offered!

Common Vehicle Applications

The 460 powered a diverse range of vehicles during its three-decade production run:

Passenger Car Applications

- Lincoln Continental (first application in 1968)

- Lincoln Mark series

- Mercury Marquis and Colony Park

- Ford LTD and Country Squire

- Ford Thunderbird

Truck and Commercial Applications

- F-Series trucks (F-250, F-350, and F-450)

- E-Series vans (Econoline)

- Motorhome chassis

- Commercial truck applications

The engine remained in truck applications well after it was discontinued in passenger cars, finally ending production in 1998 when it was replaced by Ford’s Triton V10 in heavy-duty applications.

Common Issues and Reliability Factors

Despite their overall robustness, 460 engines have some known issues to watch for:

Oil Consumption

Some 460s develop oil consumption issues, particularly as they age. This is often related to:

- Worn valve seals

- Degraded piston rings

- Oil leaks from various gaskets and seals

Regular maintenance and timely repairs can mitigate most of these concerns.

Cooling System Needs

With their large displacement, 460s generate significant heat:

- A properly sized radiator is essential

- Electric cooling fans are a worthwhile upgrade

- Water pumps should be replaced preventatively

Overheating is the enemy of any engine, but particularly so for these big blocks where warping can lead to expensive repairs.

Fuel Economy Realities

There’s no getting around it – the 460 is thirsty:

- 8-12 MPG is typical for stock truck applications

- Performance builds often see single-digit fuel economy

- Modern fuel injection helps somewhat but can’t overcome physics

Anyone considering a 460-powered vehicle should budget accordingly for fuel costs.

Building a Performance 460: Key Considerations

For those looking to extract more power from a 460, several upgrade paths exist:

Camshaft Selection

The camshaft is critical to determining the engine’s power characteristics:

- Stock-replacement cams improve drivability while maintaining torque

- RV cams enhance mid-range power, ideal for towing

- Performance grinds shift the power band higher for more peak horsepower

For street applications, a cam with approximately 220-230 degrees of duration at 0.050″ lift provides an excellent balance of power and drivability.

Intake Manifold Options

Intake manifold selection significantly impacts power delivery:

- Dual-plane designs enhance torque and low-end response

- Single-plane manifolds favor top-end power

- EFI-compatible intakes allow modern fuel delivery with classic looks

The Edelbrock Performer RPM has proven to be one of the most versatile options for street-driven 460 builds, offering an excellent balance of power across the RPM range.

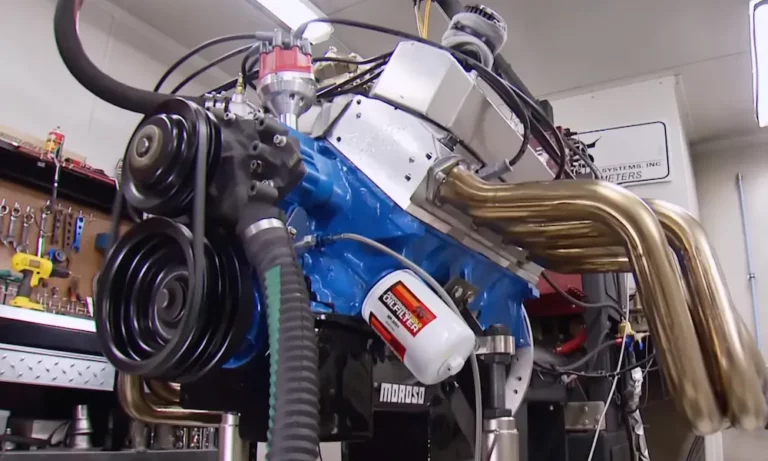

Exhaust System Improvements

The restrictive nature of stock exhaust components makes this area ripe for improvement:

- Headers provide immediate power gains (typically 20-30 hp)

- 3-inch exhaust systems reduce backpressure

- H-pipe or X-pipe designs improve scavenging effects

A complete exhaust system upgrade from headers to tailpipes can yield impressive power gains while also delivering that signature big-block sound.

The Legacy of Ford’s 460 Engine

The Ford 460 big block represents a significant chapter in American automotive engineering. Despite being designed in an era of cheap fuel and minimal emissions concerns, the platform proved remarkably adaptable, surviving three decades of regulatory changes.

Today, the engine continues to be celebrated for its:

- Straightforward design and serviceability

- Massive torque output

- Enormous potential for performance enhancement

- Strong aftermarket support

- Well-documented quirks and solutions

For enthusiasts looking for raw power in a traditional package, the 460 remains an attractive option with extensive aftermarket support and a well-understood architecture. Whether powering a classic restoration, a modern hot rod, or a working truck, the Ford 460 continues to deliver the kind of big-displacement performance that made American V8s legendary.

This versatile big block may have left production more than two decades ago, but its impact on Ford’s performance legacy and its continued popularity among enthusiasts ensure that the 460 will remain relevant for decades to come.