Are you considering a Honda with a K24 engine or thinking about swapping one into your project car? You’re looking at one of the most respected four-cylinder engines ever made. With nearly two decades of production history and a massive aftermarket following, the K24 has earned its reputation for balancing everyday reliability with serious performance potential.

By the end of this article, you’ll understand exactly what makes the K24 special, its key specs across different variants, and why it remains a favorite among both daily drivers and tuning enthusiasts.

What is the K24 Engine?

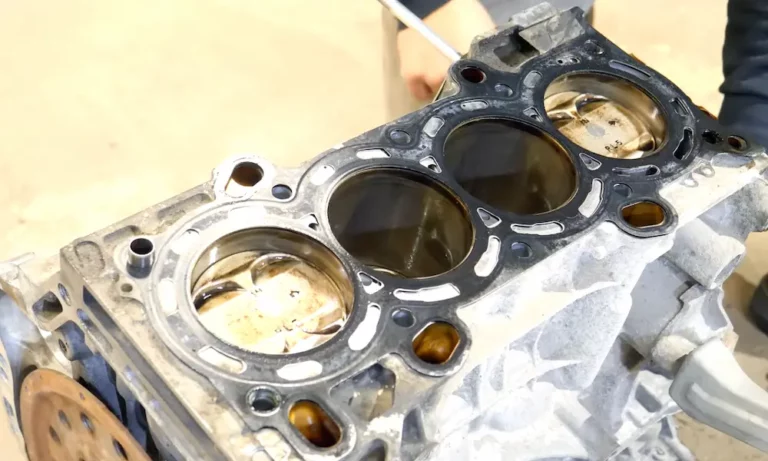

The K24 is a 2.4-liter inline-four engine produced by Honda since 2001. It’s part of Honda’s K-series engine family, featuring an aluminum block and cylinder head construction that keeps weight down while providing excellent heat dissipation.

The engine’s full displacement is 2,354cc, achieved through a perfect balance of bore and stroke dimensions. Unlike some engines that favor one dimension over the other, the K24 strikes a balance that allows for both low-end torque and high-rpm power.

What truly sets the K24 apart is Honda’s innovative i-VTEC system (intelligent Variable Valve Timing and Lift Electronic Control). This technology effectively creates two engines in one: an efficient, sensible engine for everyday driving that transforms into a high-revving performance machine when you push it.

Basic K24 Engine Specifications

Let’s break down the fundamental specs that define the K24 engine:

- Displacement: 2,354cc (2.4 liters)

- Configuration: Inline 4-cylinder

- Valvetrain: DOHC (Dual Overhead Camshaft) with 16 valves

- Valve Control System: i-VTEC

- Block/Head Material: Aluminum alloy

- Deck Height: 231.5mm

- Fuel System: Electronic multi-port fuel injection

- Ignition: Coil-on-plug

What makes the K24 special compared to its K20 sibling is the dimensional changes Honda made. Engineers enlarged the bore by 1mm and increased the stroke by 13mm, resulting in 200cc more displacement than the K20. This strategic enlargement maintained the engine’s ability to rev while providing noticeably improved mid-range torque.

The stock fuel injectors are typically 270cc units, though many enthusiasts upgrade these when pursuing more power. Compression ratios vary across different K24 variants, with earlier models featuring around 9.6:1 and later performance versions using higher compression designs.

K24 Engine History and Development

The K24 made its debut in 2001 in the Honda CR-V, replacing the aging F23A engine. It represented Honda’s commitment to evolving their four-cylinder architecture to meet changing needs for performance, efficiency, and emissions.

This wasn’t just a larger version of an existing engine—it was a thoroughly modern design incorporating Honda’s latest technological advancements. The K24’s introduction coincided with Honda’s deployment of increasingly sophisticated i-VTEC technology, offering more refined control over valve timing and lift compared to earlier VTEC systems.

Throughout its production run, Honda continuously refined the platform through several evolutionary stages:

- K24A Series (Early 2000s) – The original variants establishing the foundation

- K24Z Series (Mid-2000s to early 2010s) – Refined versions with improvements to efficiency and emissions

- K24W Series (2010s) – The final evolution of the platform with the most modern features

This continual development allowed Honda to maintain the K24’s fundamental character while adapting it to meet changing regulations and consumer expectations. The engine’s nearly two-decade production run across multiple vehicle platforms speaks volumes about its fundamental design excellence.

Major K24 Variants and Their Specifications

The K24 family includes numerous variants, each with specifications tailored to specific applications and performance targets. Here’s a breakdown of the most significant variants:

K24A1 (2001-2006)

- Power: 160 hp @ 5,500 rpm

- Torque: 162 lb-ft @ 4,500 rpm

- Compression Ratio: 9.6:1

- Features: i-VTEC on intake camshaft only, 35mm intake valves, 30mm exhaust valves

- Applications: Early Honda CR-V models

- Notes: Used a variable geometry intake manifold (Honda’s 2-stage PPA design) and a 60mm throttle body

K24A4

- Power: 160 hp @ 5,500 rpm

- Torque: 161 lb-ft @ 4,500 rpm

- Compression Ratio: 9.7:1 (slight increase from K24A1)

- Applications: Honda Element, some Honda Accord models

- Notes: Featured modified intake and exhaust ports and an aluminum single-stage RAA intake manifold

K24A2

- Power: 200-205 hp @ 6,800 rpm

- Torque: 164-171 lb-ft @ 4,500 rpm

- Compression Ratio: 10.5:1

- Features: i-VTEC on both intake and exhaust camshafts

- Applications: Acura TSX

- Notes: Higher performance variant with more aggressive camshafts and tuning

K24Z3

- Power: 201 hp @ 7,000 rpm

- Torque: 170 lb-ft @ 4,400 rpm

- Compression Ratio: 11.0:1

- Applications: Honda Civic Si (2012-2015)

- Notes: Featured improved emissions controls and efficiency

This table compares the output of key K24 variants:

| Variant | Horsepower | Torque | Compression | Notable Features |

|---|---|---|---|---|

| K24A1 | 160 hp | 162 lb-ft | 9.6:1 | Original CR-V engine |

| K24A4 | 160 hp | 161 lb-ft | 9.7:1 | Element, some Accords |

| K24A2 | 200-205 hp | 164-171 lb-ft | 10.5:1 | Performance variant for Acura TSX |

| K24Z3 | 201 hp | 170 lb-ft | 11.0:1 | Later Civic Si, improved emissions |

Each variant maintained the core K24 identity while being tailored for specific vehicles and performance profiles.

Performance Characteristics

What makes the K24 engine special to drive? Its performance character combines everyday usability with enthusiast-pleasing traits in a way few engines manage.

In stock form, the engine offers a perfect balance between low-end torque and high-rpm excitement. The i-VTEC system deserves much credit for this dual personality. At lower rpms, the engine prioritizes efficiency and torque, making daily driving smooth and effortless. Push the revs higher, and there’s a noticeable transition as the VTEC engages, delivering a more aggressive cam profile and increased valve lift that transforms the engine’s character.

The 2.4-liter displacement provides substantially improved mid-range torque compared to smaller engines, making the K24 particularly well-suited for daily driving situations. You’ll notice this as significantly better response when accelerating from 2,000-4,000 rpm without requiring a downshift.

The engine’s redline varies across different applications, but most K24s comfortably rev to 6,800-7,000 rpm from the factory. When modified, they can safely operate at even higher rpms—some purpose-built racing versions can reach 10,000 rpm.

When compared to larger engines (like V6s or V8s) with similar horsepower ratings, the K24 exhibits a distinctly different power delivery. While a V8 might provide consistent torque throughout the rev range, the K24 concentrates its power in the higher rpm bands, rewarding drivers who aren’t afraid to rev the engine.

This creates an engaging driving experience that many enthusiasts prefer—especially those who enjoy the sensation of an engine that feels increasingly eager as the revs climb rather than the instant-everywhere torque of modern turbocharged alternatives.

Applications in Honda and Acura Vehicles

The K24’s versatility led to its widespread use across numerous Honda and Acura models. Here’s where you’d find this engine throughout its production run:

Honda Models

- CR-V (2002-2014): Various K24 versions powered multiple generations

- Accord (2003-2014): Four-cylinder models used K24 variants

- Element (2003-2011): Used the K24A4 variant

- Civic Si (2012-2015): Featured the higher-output K24Z3

Acura Models

- TSX (2004-2014): Used higher-performance K24A2

- ILX (2013-2015): Featured the K24 in certain trim levels

- RDX (First generation): Early models before switching to turbocharged engines

The engine’s implementation varied across these vehicles. In family-oriented models like the CR-V and Element, the K24 was tuned for everyday drivability with an emphasis on low-end torque and fuel economy. In sportier applications like the Civic Si and Acura TSX, the engine received more aggressive tuning with higher compression ratios and more sophisticated valvetrain components to enhance high-rpm performance.

This adaptability across different market segments speaks to the fundamental strengths of the K24 architecture and its ability to be effectively tailored for diverse vehicle requirements.

Reliability and Common Issues

One of the K24’s most outstanding attributes is its exceptional reliability. When properly maintained, these engines routinely last well beyond 200,000 miles—some reaching 300,000+ miles with only basic maintenance.

This longevity stems from Honda’s conservative engineering, robust materials, and refined manufacturing processes. The K24’s aluminum block and head construction provides excellent heat dissipation, while the chain-driven camshaft system offers durability advantages over belt-driven alternatives found in some competitor engines.

Despite this overall reliability, there are some maintenance considerations K24 owners should know:

- Valve Adjustments: Unlike some modern engines with hydraulic lifters, the K24 uses solid lifters requiring periodic valve clearance checks and adjustments (typically every 100,000 miles)

- Timing Chain: While generally more durable than timing belts, the chain should still be inspected at higher mileages

- Oil Consumption: Some early K24 variants may develop increased oil consumption at higher mileages, though this isn’t universal across all applications

Some specific model years and applications had their own quirks. For example, some 2008-2010 Accord models experienced premature wear of the variable valve timing actuators, which might require replacement around 100,000 miles.

The K24’s fundamental engineering makes it particularly forgiving of minor maintenance delays, though adhering to recommended service intervals remains important for maximizing longevity. This combination of inherent durability and reasonable maintenance requirements has made the K24 popular not just in original applications but also as a swap candidate for project cars where reliability is valued alongside performance potential.

Tuning Potential and Modifications

The K24 has developed a massive following in the performance aftermarket due to its exceptional responsiveness to modifications and robust construction that can handle significant power increases.

Popular K24 Modifications Include:

Naturally Aspirated Builds

- Intake and exhaust upgrades (cold air intake, header, exhaust system)

- Higher compression pistons

- Performance camshafts with more aggressive profiles

- Cylinder head porting and polishing

- Throttle body upgrades

- ECU tuning

Forced Induction

- Turbocharger kits (capable of 400+ hp with supporting mods)

- Supercharger systems

- Upgraded fuel system components

- Forged internals for high-boost applications

The K20/K24 Hybrid (“Frankenstein” Build)

One of the most popular and effective modifications involves combining a K20 cylinder head with a K24 block. This approach takes advantage of the K20 head’s superior flow characteristics and typically higher-performance valvetrain while retaining the K24’s larger displacement. The result offers improved high-rpm breathing while maintaining the torque benefits of the larger displacement—creating a particularly well-rounded performance profile.

A fully built K24 can produce impressive power numbers. Naturally aspirated race-built K24 engines have been documented producing up to 500 horsepower, while turbocharged versions can achieve 600+ horsepower with the right supporting modifications.

The engine responds differently to modifications compared to other platforms. For example, when comparing a modified K24 to a V8 like an LS3 at similar power levels, the K24 typically delivers its power at much higher rpm ranges. This creates a distinctly different driving experience that many Honda enthusiasts prefer—the sensation of a smaller engine that becomes increasingly powerful as the revs climb rather than the immediate torque hit of a larger displacement engine.

Comparison with Other Engines

How does the K24 stack up against other engines in its class and beyond? Here’s how it compares to some notable alternatives:

Vs. Toyota 2.4L (2AZ-FE)

- Power/Torque: The K24 generally provides similar power but with better high-rpm performance

- Construction: Both use aluminum blocks/heads, but K24 typically shows better durability

- Technology: K24’s i-VTEC system offers more sophisticated valve control than Toyota’s VVT-i

- Tuning Potential: K24 has significantly more aftermarket support and modification potential

Vs. Mazda 2.3L MZR

- Performance: Similar baseline output, but K24 typically offers better high-rpm characteristics

- Refinement: K24 generally provides smoother operation with less NVH (noise, vibration, harshness)

- Reliability: Both have good reliability records, though the K24’s timing chain offers advantages over the MZR’s timing belt in some applications

Vs. V6 and V8 Engines (Similar Horsepower)

When comparing a modified K24 to larger displacement engines producing similar power figures, the differences become more pronounced:

- Power Delivery: The K24 concentrates power in the higher rpm bands, while V6/V8 engines typically provide more consistent torque throughout the rev range

- Response Characteristics: V8s provide stronger acceleration from lower speeds, while the K24 requires higher engine speeds to deliver maximum performance

- Weight and Packaging: The K24 offers significant advantages in weight and compact dimensions

- Driving Experience: Fundamentally different character—the K24 rewards drivers who enjoy working the gears and keeping the engine in its power band

This unique combination of attributes explains why the K24 maintains a dedicated following even as new technologies emerge. While modern turbocharged engines may offer greater peak power and torque figures, many enthusiasts continue to prefer the linear power delivery, immediate throttle response, and engaging high-rpm character of the naturally aspirated K24.

K24 Engine Maintenance and Care

Proper maintenance is crucial for maximizing the K24’s legendary reliability potential. Here’s a comprehensive breakdown of key maintenance items:

Regular Maintenance Schedule

- Oil Changes: Every 5,000-7,500 miles using quality synthetic oil (5W-20 or 5W-30 depending on climate)

- Air Filter: Inspection every 15,000 miles, replacement as needed

- Spark Plugs: Replace every 100,000 miles (NGK or Denso are preferred brands)

- Valve Adjustments: Check and adjust every 100,000 miles

- Timing Chain: Inspection recommended around 150,000 miles

- Coolant: Replace every 60,000 miles or 5 years

Oil Selection

The K24 is somewhat particular about oil quality. Honda engines generally prefer quality synthetic oils with proper certification. Most factory applications specify 5W-20, though some performance-oriented variants recommend 5W-30. For modified engines producing significantly more power than stock, many builders prefer slightly heavier viscosity oils like 10W-30.

Common Maintenance Pitfalls to Avoid

- Neglecting valve adjustments: Unlike many modern engines with hydraulic lifters, the K24’s solid lifter design requires periodic adjustment to maintain proper valve clearances. Skipping this service can lead to poor performance and potentially valve train damage over time.

- Using poor quality oil filters: The K24’s oil passages and VTC (Variable Timing Control) system can be sensitive to contamination. Always use quality filters (OEM Honda or premium aftermarket options).

- Ignoring cooling system maintenance: The all-aluminum construction benefits from proper cooling. Maintain the cooling system with regular coolant changes and radiator inspections.

- Over-revving a cold engine: While the K24 loves to rev when warmed up, it’s important to allow proper warm-up before pushing the engine to high rpm ranges.

For those using a K24 in performance applications, additional considerations include more frequent oil changes, upgraded cooling components, and careful monitoring of engine parameters, especially if running forced induction.

K24 Future Classic Status and Value

As the automotive world transitions toward electrification, naturally aspirated engines like the K24 are increasingly appreciated for their mechanical purity and direct driver engagement. This has positioned well-maintained K24-powered vehicles as emerging modern classics with potentially appreciating values.

The K24’s status in the enthusiast community has been steadily growing, particularly as newer engines become increasingly turbocharged and electronically isolated. The engine’s combination of high-revving character, reliability, and tuning potential creates a driving experience that’s becoming harder to find in new vehicles.

Certain K24-powered models have already shown strong value retention or appreciation:

- The 2006-2008 Acura TSX with 6-speed manual transmission has developed a particularly strong following, with well-maintained examples commanding premium prices

- The 2012-2015 Honda Civic Si (the only Civic Si generation to use the K24 rather than a K20) has also maintained strong values

- Even more mainstream applications like manual transmission Accord coupes with the K24 are becoming increasingly sought after

For those considering a K24-powered vehicle as an investment, the best approach is to seek examples with:

- Complete maintenance history

- Unmodified or tastefully modified condition

- Manual transmission (which generally commands higher values in the enthusiast market)

- Lower mileage, though thanks to the K24’s durability, even higher mileage examples can be valuable if properly maintained

As newer vehicles become increasingly computerized and electronically controlled, the relatively analog nature of the K24 and its host vehicles appeals to enthusiasts seeking a more direct connection to their driving experience.