Looking to understand what makes the LY6 tick? Whether you’re planning an engine swap or just curious about this powerhouse, you’ve come to the right place. The LY6 6.0L V8 is one of GM’s most robust offerings, combining old-school durability with modern performance potential. Let’s dive into what makes this engine special.

What Is the LY6 Engine?

The LY6 is a 6.0-liter V8 engine developed by General Motors as part of their Generation IV LS engine family. Built between 2007 and 2010, it was primarily designed for heavy-duty trucks and SUVs where durability and torque were essential.

What sets the LY6 apart is its iron-block construction paired with aluminum heads—giving you the best of both worlds: exceptional strength where it counts and weight savings where possible. Unlike its aluminum-block cousins found in performance cars, the LY6 was built to handle serious work.

You can identify an LY6 by looking for the “K” in the eighth position of the vehicle identification number. This workhorse powered several GM vehicles during its production run, earning a reputation for reliability in demanding applications.

Core LY6 Specs: The Numbers That Matter

The LY6 comes with impressive specifications that make it stand out among LS family engines:

| Specification | Detail |

|---|---|

| Displacement | 6.0L (364 cubic inches) |

| Block Material | Cast Iron |

| Cylinder Head Material | Aluminum |

| Bore | 4.000 inches (101.6mm) |

| Stroke | 3.622 inches (92mm) |

| Compression Ratio | 9.6:1 |

| Horsepower | 364-385 hp @ 5,400-5,600 RPM |

| Torque | 383-400 lb-ft @ 4,200-4,400 RPM |

| Redline | 5,600 RPM (fuel cutoff) |

| Weight | 539 lbs (245 kg) |

The slightly undersquare design (bore smaller than stroke) explains why this engine delivers such impressive torque at lower RPMs—exactly what you want for hauling heavy loads. The moderate 9.6:1 compression ratio allows it to run on regular unleaded fuel while still providing good combustion efficiency.

Vehicles Equipped With the LY6 Engine

You’ll find the LY6 powering several heavy-duty GM vehicles from 2007 to 2010:

Trucks:

- 2007-2010 Chevrolet Silverado 2500 HD, 3500 HD

- 2007-2010 GMC Sierra 2500 HD, 3500 HD

SUVs:

- 2007-2009 Chevrolet Suburban 2500

- 2007-2009 GMC Yukon XL 2500

Vans:

- 2008-2009 Chevrolet Express 2500, 3500

- 2008-2009 GMC Savana 2500, 3500

Notice a pattern? These are all work-oriented vehicles designed for towing, hauling, and commercial applications—exactly where the LY6’s strengths shine brightest.

Key Technical Features That Set the LY6 Apart

The LY6 incorporates several advanced features that enhance its performance and durability:

Cast Iron Block Construction

Unlike many other LS engines that use aluminum blocks, the LY6 retains a cast iron block for maximum strength. This makes it heavier but significantly more robust—especially important when adding boost or building for extreme power.

Variable Valve Timing (VVT)

The LY6 features VVT, which continuously adjusts valve operation based on driving conditions. This technology optimizes performance across the entire RPM range, improving both power delivery and fuel efficiency.

Rectangular-Port Cylinder Heads

The aluminum heads use rectangular intake ports similar to those found on the LS3. This design provides better airflow compared to the cathedral-port designs used on earlier LS engines, enhancing both torque production and high-RPM breathing.

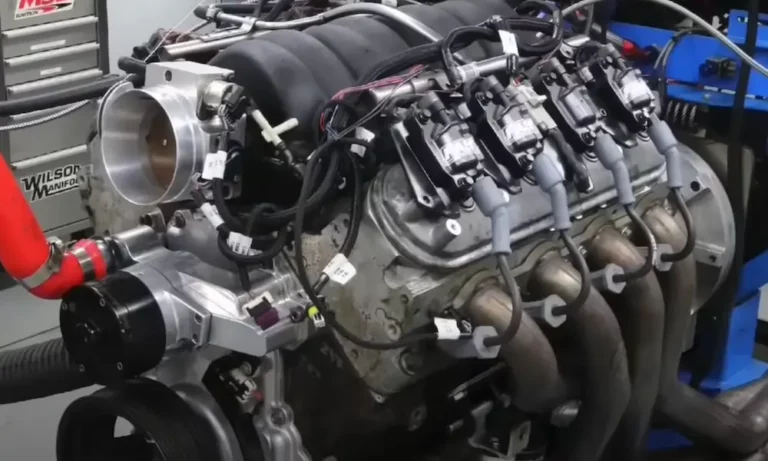

Advanced Ignition System

A coil-near-plug ignition setup ensures precise spark delivery to each cylinder. This system improves combustion efficiency while reducing maintenance needs—no distributor to worry about and more accurate timing control.

Performance Characteristics: How Does It Feel?

In stock form, the LY6 delivers approximately 364-385 horsepower and 383-400 lb-ft of torque. These aren’t just numbers on paper—they translate to real-world performance that makes these engines so desirable.

The torque curve peaks around 4,200-4,400 RPM, but what’s more impressive is how flat that curve remains throughout the midrange. This gives you predictable, usable power exactly when you need it. The engine doesn’t need to be revved to the moon to deliver its punch—perfect for towing a trailer up a steep grade or accelerating a heavy truck.

The fuel cutoff at 5,600 RPM tells you something important about this engine’s purpose: it’s built for low-end grunt rather than high-RPM screaming. That said, it still delivers impressive horsepower for its era and application.

Modifying the LY6: Unleashing Hidden Potential

Here’s where things get exciting. The LY6 has become a favorite among performance enthusiasts because it responds exceptionally well to modifications. That cast iron block provides an incredible foundation for building serious power.

Most Popular LY6 Upgrades

- Camshaft Upgrades: The factory cam is conservative. Swapping in a more aggressive camshaft can wake up the engine dramatically, often adding 30-50 horsepower with the right supporting mods.

- Forced Induction: The iron block makes the LY6 an excellent candidate for superchargers and turbochargers. With the right setup, 600+ horsepower is achievable while maintaining reliability.

- Intake System Improvements: Cold air intakes, ported throttle bodies, and improved manifolds can significantly enhance airflow.

- Exhaust System Upgrades: Headers and a high-flow exhaust system reduce backpressure and let the engine breathe better.

- Displacement Increases: Many builders stroke these engines to 408 cubic inches, significantly increasing torque output. A modified 408 cubic inch LY6 build can achieve around 550 horsepower and 540 lb-ft of torque.

How the LY6 Compares to Other LS Engines

The LY6 sits within a large family of LS engines, each with its own characteristics:

LY6 vs. L96

These engines are nearly identical in specs and performance. The main difference? The L96 is flex-fuel capable (can run on E85), while the LY6 isn’t. The L96 eventually replaced the LY6 starting in 2010.

LY6 vs. LS2/LS3

The most significant difference here is construction—the LS2 and LS3 use aluminum blocks while the LY6 uses cast iron. The LY6 shares similar rectangular-port head design with the LS3 but is tuned more for torque than high-RPM horsepower.

LY6 vs. L76

The L76 uses an aluminum block and includes Active Fuel Management in some applications—a cylinder deactivation system not found on the LY6. Both share similar displacement, but the L76 was used in more performance-oriented applications.

Common LY6 Issues and How to Address Them

Even the mighty LY6 isn’t without a few potential trouble spots:

AFM Oil Consumption

While the LY6 doesn’t have Active Fuel Management (cylinder deactivation), some related components can cause oil consumption issues in high-mileage engines. Replacing valley cover gaskets and PCV components often resolves these problems.

Valve Spring Failures

Stock valve springs can weaken over time, especially in modified engines. Upgrading to performance valve springs is recommended if you’re increasing RPM capability or adding boost.

Cooling System Maintenance

These engines run hot when worked hard. Regular cooling system maintenance is essential, particularly if using the engine for towing. A quality cooling system upgrade can make a significant difference in reliability.

The LY6 as a Swap Candidate

The LY6 has become incredibly popular for engine swaps, and for good reason:

- Abundant Supply: These engines were used in numerous heavy-duty trucks and are relatively easy to find in salvage yards.

- Cost-Effective: Compared to aluminum LS engines, the LY6 often costs less while providing an excellent foundation for modifications.

- Strength: The iron block can handle significant power increases without requiring extensive reinforcement.

- Compatibility: Being part of the LS family means vast aftermarket support and compatibility with many transmission options.

Popular swap applications include classic trucks, muscle cars, and offroad vehicles where the LY6’s torque characteristics and durability are highly valued. The extra weight of the iron block can be a consideration for lightweight applications, but the tradeoff in strength often outweighs this concern.

The Future of the LY6: Still Relevant Today

Despite ending production in 2010, the LY6 remains extremely relevant in today’s performance landscape. As emissions regulations tighten and newer engines become increasingly complex, the relatively simple design of the LY6 makes it appealing for enthusiasts who want a straightforward, reliable powerplant that can be easily modified.

The engine’s iron block construction also gives it staying power in an era where aluminum blocks are the norm. For high-horsepower builds and forced induction applications, that added strength remains a significant advantage that keeps the LY6 in demand.

Getting the Most from Your LY6

If you’re fortunate enough to own a vehicle with an LY6 or are considering one for a project, here are some tips for maximizing its potential:

- Maintain It Properly: Regular oil changes with quality synthetic oil will help these engines last virtually forever.

- Address Known Issues Early: Take care of any valve cover or intake manifold gasket issues promptly to prevent oil consumption problems.

- Consider a Mild Cam Upgrade: Even if you’re not building for maximum power, a slightly more aggressive camshaft can wake up the engine significantly without hurting reliability.

- Upgrade the Exhaust: The factory exhaust systems on many LY6-equipped vehicles are restrictive. A performance exhaust system can free up some power while giving your truck a more aggressive sound.

The LY6 6.0L V8 represents one of GM’s most capable workhorses—a perfect blend of old-school durability and modern performance potential. Whether you’re maintaining one in its original application or building it into a fire-breathing monster, this iron-block powerhouse continues to impress with its capability, reliability, and untapped potential.