Looking for oil around your Subaru’s engine bay? That telltale leak might be coming from your valve cover gaskets. It’s one of the most common issues on high-mileage Subarus, especially given the boxer engine’s unique design. But don’t worry – replacing these gaskets yourself can save you hundreds of dollars and protect your engine from serious damage.

Why Subaru Valve Cover Gaskets Fail

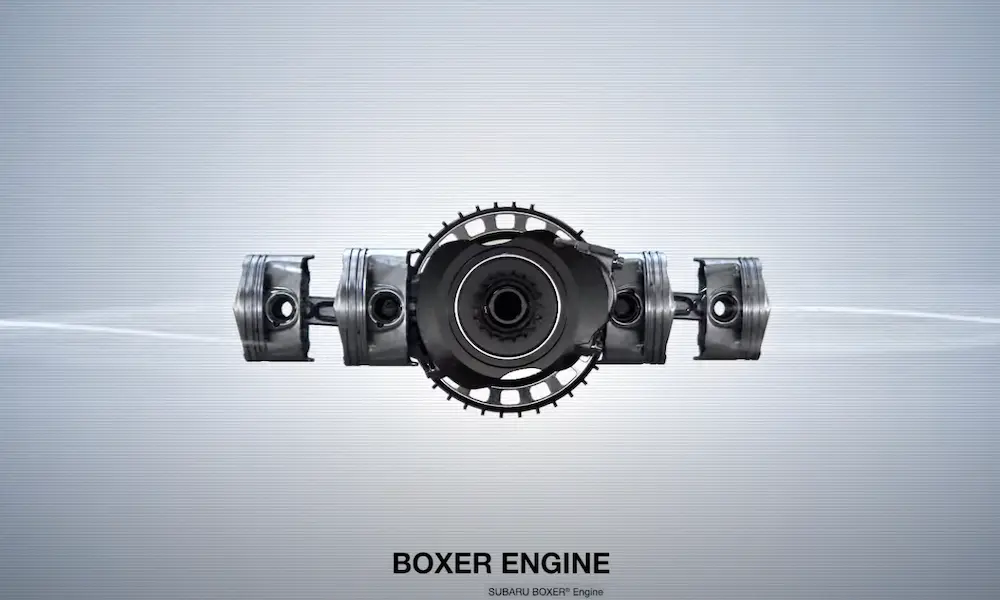

The Boxer Engine Design Problem

Subaru’s flat-four engine layout places both valve covers in a vulnerable position – low in the engine bay where they’re constantly exposed to heat cycling, vibration, and road spray. This accelerates gasket wear compared to other engine designs.

The valve cover seal system consists of:

- A molded silicone perimeter gasket

- Four spark plug tube seals

- Plastic “half-moon” cam plugs (on EJ and early FB engines)

Signs Your Valve Cover Gaskets Need Replacing

You’ll likely notice these symptoms if your gaskets are failing:

- Oil film collecting on the lower edge of the valve cover or engine cradle

- Blue smoke or burning oil smell after shutdown (from oil hitting the hot exhaust)

- Misfire codes (P03xx) as oil seeps into coil packs and spark plug boots

- Gradual loss of oil between changes without visible puddles

Don’t ignore these warning signs! Replacing gaskets promptly prevents oil fires, protects expensive electrical components, and costs far less than an engine-out head gasket replacement.

Cost Comparison: DIY vs Professional Replacement

The national average for professional valve cover gasket replacement ranges from $331-$455, with labor making up the bulk of that cost. But on Subaru boxer engines, expect to pay more:

| Model | Professional Cost Range |

|---|---|

| Outback | $348-$1,021 |

| Forester | $276-$1,035 |

DIY costs breakdown:

- OEM gasket set: $30-$50

- Black RTV sealant: $10

- Brake cleaner and rags: $10

- New bolt grommets: $12

- Optional billet cam plugs: $50 (lifetime solution)

Total DIY cost: $60-$130 (saving you $300-$900)

Tools You’ll Need

| Tool | Purpose |

|---|---|

| 10mm shallow & deep sockets with 3″ and 6″ extensions | For all cover bolts, battery hold-down, intake duct |

| 12mm socket | Engine mount nut (if jacking the motor) |

| ¼-inch torque wrench capable of 56 in-lb / 4.7 ft-lb | Prevents stripping the M6 cover posts |

| Flex-head 10mm ratcheting wrench | Accessing rear lower bolts by the frame rail |

| Plastic trim pliers | Removing hose clamps and PCV hose |

| Carbide scraper & brake cleaner | Cleaning old RTV and sludge |

| Small magnet | Retrieving dropped bolts |

Step-by-Step Replacement Guide

Preparation

- Work on a cool engine to avoid burns – let it sit at least 2 hours after driving.

- Disconnect the battery by removing the negative terminal first.

- Clear workspace access by removing the airbox (driver’s side) or battery tray (passenger side) for better working room.

- Clean the valve cover area thoroughly with compressed air to prevent debris from falling into the engine later.

Removing the Valve Cover

- Break all bolts loose using a 10mm socket. If any feel gummy, work back and forth with penetrating oil to avoid snapping the stud.

- For EJ engines: You might need to remove the 14mm engine mount nut and jack under the oil pan with a wood block to gain an extra 15-20mm clearance, especially on the passenger side.

- Carefully lift the cover by tapping gently with a plastic dead-blow hammer to break the seal. Maneuver it past wiring harnesses without forcing or bending the sealing rail.

Cleaning and Preparation

- Protect the valvetrain by placing a clean rag over the exposed area.

- Remove all old gasket material with a plastic scraper, paying special attention to:

- The hump over the cam cap

- Half-moon plug areas

- Bolt holes and sealing surfaces

- Clean all surfaces with brake cleaner until the metal is completely bare and dry.

- Inspect the valve cover for warping or damage – a bent cover won’t seal properly no matter how good your new gasket is.

Installing the New Gasket

- Replace spark plug tube seals and press them fully into position in the valve cover.

- If you have half-moons: Apply a thin film of RTV around their perimeter and seat them flush. Consider upgrading to billet aluminum versions from IAG Performance or Company23 for a permanent fix.

- Seat the new perimeter gasket into the valve cover channel dry. If it keeps popping out, a tiny dab of High-Tack can hold it in place.

- Apply RTV at only four specific points:

- A 4mm bead on each end of the cam-cap hump

- Across each half-moon saddle

- NEVER coat the entire gasket with RTV!

Reinstallation

- Place the valve cover carefully onto the head, aligning all bolt holes.

- Install new rubber bolt grommets on all six bolts and hand-start them to prevent cross-threading.

- Follow the correct tightening sequence:

- Center-top → Center-bottom → Upper-right → Lower-left → Lower-right → Upper-left

- First pass: snug lightly in this sequence

- Wait 15 minutes for RTV to skin over

- Final pass: torque to exactly 56 in-lb (4.7 ft-lb) in the same sequence

- Double-check the torque on the two center bolts – they’re critical for preventing leaks.

- Reinstall all components – coil packs, fuel rail shield, battery or airbox, and engine mount nut (52 ft-lb if removed).

Initial Test and Break-In

- Before reconnecting battery, verify all electrical connections are secure.

- Start the engine and idle for five minutes while watching for drips.

- Expect light smoke initially as residual oil burns off the exhaust – this should disappear after a few short drives.

Model-Specific Tips

For EJ25 Engines (2000-2010 Outback/Forester/Impreza)

- The passenger-side cover often hits the frame rail – jacking the engine or removing the motor mount makes extraction much easier.

- Always replace the cork-style bolt washers, as worn ones will allow leaks even with a new gasket.

- The half-moon seals are notorious failure points – consider the billet aluminum upgrade.

For FB25 Engines (2011-present Outback/Forester/Crosstrek)

- The intake manifold doesn’t need removal, but be careful with rear coil connectors – use a small pick to depress the tab before pulling to avoid breaking them.

- Plastic covers have integral spark plug tube seals – inspect these carefully.

- Torque specs and sequence remain identical to older models.

For Turbo Models (WRX/STI, XT)

- Two extra bolts hide under the timing cover – remove its 10mm screws for access.

- The factory service manual specifies Fujibond instead of generic RTV on DOHC cam-cap joints.

- Heat cycling from turbo operation means these gaskets typically fail earlier than naturally aspirated models.

Preventing Future Leaks

- Never over-torque the cover bolts – stripped posts are the #1 cause of recurring leaks because the cover can no longer clamp evenly.

- Use only OEM or high-quality Fel-Pro gaskets – cheap online sets are thinner and collapse within months.

- Consider billet half-moon plugs – the aluminum versions withstand heat cycling and multiple services without deteriorating.

- Change your PCV valve every 60,000 miles – excess crankcase pressure will force oil past even new gaskets.

- Plan ahead – most quality gaskets last around 100,000 miles, so consider scheduling your next valve-cover service alongside spark plugs and valve clearance checks to save labor time.

Common Mistakes to Avoid

- Rushing the job – fighting with tight clearances leads to broken parts. Budget 3-6 hours for FB engines, 5-8 hours for EJ models.

- Skipping new bolt grommets – these rubber washers are essential for proper sealing and cost only a few dollars.

- Using excessive RTV – more isn’t better! Too much can squeeze into the engine and clog oil passages.

- Torquing unevenly – always follow the proper sequence to ensure even clamping force.

- Ignoring half-moon leaks – these are often the real culprit when valve cover gaskets keep failing.

With patience and attention to detail, replacing your Subaru’s valve cover gaskets is entirely DIY-friendly. You’ll save hundreds of dollars, prevent oil fires, protect your electrical components, and keep your driveway clean for another 100,000 miles. The most critical factors are using the correct 4.7 ft-lb torque specification and applying RTV only where needed.

After completing this repair, you’ll understand why Subaru owners develop such attachment to their unique boxer engines – they’re different, but completely manageable with the right knowledge.