Shopping for a replacement transmission or planning an LS swap? You’ve probably stumbled across the 4L60E and 4L65E and wondered if they’re actually different or just marketing speak. Here’s the truth: they look nearly identical on the outside, but what’s inside tells a completely different story. Let’s break down what separates these two workhorses and whether you can swap one for the other.

What Makes the 4L65E Different from the 4L60E?

The 4L65E isn’t a new design—it’s a beefed-up version of the 4L60E built to handle more punishment. GM introduced the 4L65E in 2001 specifically for high-torque applications like the 6.0L engines in Escalades and Silverado SS trucks.

Think of it this way: the 4L60E is your reliable daily driver transmission, good for about 360 lb-ft of torque. The 4L65E is the heavy-duty variant that can handle 380-430 lb-ft without breaking a sweat.

The Key Internal Upgrades

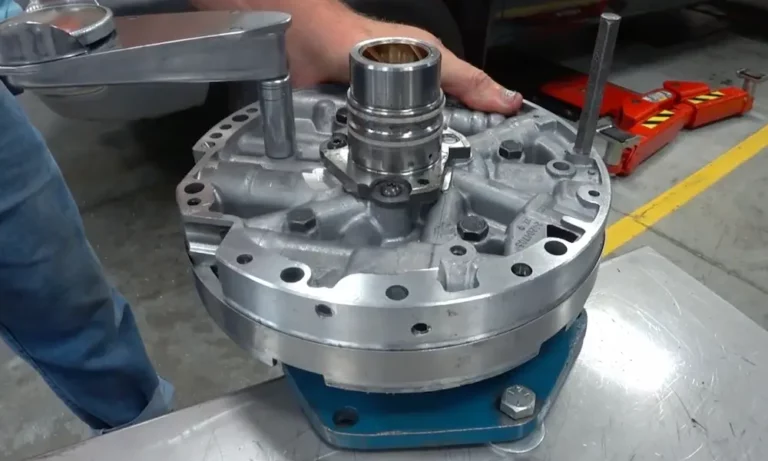

The real magic happens inside where you can’t see it:

Planetary Gears: The 4L60E uses four pinion gears in its planetary carriers. The 4L65E upgrades to five pinions, spreading the load across more contact points. That’s 25% more surface area handling the torque—critical when you’re launching a 6,000-lb truck.

Input Shaft: Every 4L65E comes with a 300mm input shaft that’s been induction hardened. This heat-treatment process creates an ultra-hard surface layer while keeping the core flexible enough to absorb shock. The standard 4L60E? It might have a 298mm or 300mm shaft, but it won’t have that critical hardening.

3-4 Clutch Pack: Space inside the input drum is tight, but GM squeezed in seven friction plates for the 4L65E versus six in the 4L60E. That extra plate increases friction surface area by about 16.6%, helping the transmission hold power during the critical 2-3 shift.

Sun Shell: This is the Achilles’ heel of the 4L60E platform. The standard version uses a steel stamping that’s prone to stripping splines or cracking at high mileage. The 4L65E gets a heat-treated heavy-duty sun shell that resists these failures.

How to Tell a 4L60E from a 4L65E

You can’t reliably identify these transmissions by looking at the case. They’re essentially identical twins on the outside.

The RPO Code Method

The Service Parts Identification (SPID) label in your glovebox is your answer. Look for these codes:

- M30 = Standard 4L60E

- M32 = Heavy-duty 4L65E

- M70 = Super heavy-duty 4L70E (introduced around 2006)

Vehicle Application Clues

The 4L65E wasn’t standard equipment. GM reserved it for specific high-performance and luxury applications:

- Cadillac Escalade/ESV/EXT (2001-2006)

- GMC Yukon Denali/Sierra Denali (2001-2006)

- Chevrolet Silverado SS (2003-2006)

- Hummer H2 (2003-2007)

- Pontiac GTO (2004-2006)

- Chevrolet Corvette C6 (2005 only)

If you’re pulling a transmission from one of these vehicles, you’ve likely got an M32.

The Input Shaft Trick

Pop the bellhousing and measure the input shaft. A 300mm shaft confirms LS-engine compatibility, but it doesn’t guarantee you’ve got a 4L65E. Standard 4L60Es in 4.8L and 5.3L trucks after 1999 also use the 300mm shaft.

The only way to confirm those heavy-duty internals? Crack it open and count the pinion gears or check for the hardened sun shell.

Can You Swap a 4L65E for a 4L60E?

Sometimes it’s plug-and-play. Other times you’ll need a degree in electrical engineering.

The Easy Swap Scenario

Target vehicle: 1999-2005 GM truck with a 4.8L or 5.3L LS engine

Donor transmission: 2001-2005 4L65E from an Escalade or Denali

This swap is beautifully simple. Both use:

- The 300mm input shaft

- The 13-pin electrical connector

- The deep LS-style bellhousing

- The same torque converter bolt pattern (11.062″)

Bolt it in, connect the harness, and you’ve just upgraded to five-pinion planets and a seven-clutch 3-4 pack without any custom work.

The Complicated Swap

Target vehicle: 1995 Camaro with an LT1 engine

Donor transmission: 2004 4L65E

Now you’re in trouble:

- Bellhousing mismatch: The LS bellhousing won’t bolt to the LT1 block

- Wrong input shaft: The 300mm shaft is too long and the pilot is incorrect for the LT1 crank

- Electronics nightmare: You’re mixing OBD-I with OBD-II, and the PWM torque converter clutch logic is completely different

You’d need to swap bellhousings, disassemble the entire transmission to change the input shaft and pump, and potentially reprogram the PCM. At that point, you’re better off rebuilding your original 4L60E with heavy-duty aftermarket parts.

The Wiring Harness Matters More Than You Think

The connector on the transmission side tells you a lot about compatibility.

13-Pin Connector (1993-2005)

This grey or green connector is standard on most 4L60Es and early 4L65Es. It carries signals for shift solenoids A and B, the pressure control solenoid, TCC solenoid, and the pressure switch manifold.

A 2003 Silverado SS 4L65E will plug right into a 2000 Silverado 1500 harness. The electronics are identical.

15-Pin Connector (2006-2008)

GM added an Input Speed Sensor (ISS) around 2006, requiring two extra pins. The connector switched to black.

Here’s the problem: if you install a 15-pin 4L65E into a pre-2006 vehicle, it’ll physically fit, but the older PCM doesn’t expect the ISS signal. Conversely, putting a 13-pin transmission into a 2006+ vehicle that expects an ISS will trigger immediate limp mode.

17-Pin Connector (2009+)

The Internal Mode Switch (IMS) moved the PRNDL switch inside the transmission case, requiring even more pins. This generation mostly appears on 4L70E units but can show up on service replacement 4L65Es.

Torque Converter Compatibility

Don’t assume your old converter will work.

The 4L65E uses the LS-specific bolt circle of 11.062 inches, which is different from the older Small Block Chevy/LT1 pattern of 10.75 inches. The LS converter also has a longer pilot hub designed for the recessed crank flange.

If you try using a non-LS converter on an LS engine without a crank spacer sleeve, the converter will wobble and destroy the pump bushing and seal within minutes.

The lockup clutch material matters too. 4L65E converters use woven carbon fiber designed to handle the controlled slip strategy of the Pulse Width Modulated TCC solenoid. If you rebuild a converter with standard paper friction material, it’ll fail quickly under the continuous slip heat.

How Much Power Can a 4L65E Handle?

GM rates the 4L65E at 380-430 lb-ft depending on the model year. In the real world, it’ll handle 450-500 flywheel horsepower in street applications.

But there’s a catch: vehicle weight and tire traction matter just as much as horsepower. A 500hp Corvette on street tires might live happily with a stock 4L65E. That same transmission behind a 500hp Silverado SS launching on slicks? You’ll likely shatter the output shaft or strip the input sprag.

Common Failure Modes

When these transmissions give up, they follow predictable patterns:

3-4 Clutch Burnout (Code P0730): The most common failure. The friction material wears, clearances open up, shift times get longer, and eventually you lose 3rd and 4th gear completely. The transmission shifts 1-2 fine but neutralizes when trying for 3rd.

Broken Sun Shell: Even the hardened M32 shell can crack under extreme shock loads—like rocking out of snow or a hard 4-2 downshift at highway speed. You’ll lose Reverse, 2nd, and 4th gears but still have 1st and 3rd.

Input Sprag Failure: The forward one-way clutch fails under high-torque launches. The sprag elements flip or the race fractures. Result? No movement in Drive or severe slipping on takeoff.

TCC Regulator Valve Wear: The constant oscillation of the PWM valve wears the aluminum valve body bore, allowing pressure to escape. This triggers the P1870 code (transmission component slipping). The PCM responds by commanding maximum line pressure, giving you bone-jarring 1-2 shifts.

Performance Comparison Table

| Feature | 4L60E | 4L65E |

|---|---|---|

| Max Torque Rating | 360 lb-ft | 380-430 lb-ft |

| Planetary Pinions | 4 pinions | 5 pinions (powdered metal) |

| 3-4 Clutch Frictions | 6 plates | 7 plates |

| Input Shaft Options | 298mm or 300mm | 300mm only (hardened) |

| Sun Shell | Standard steel | Heat-treated heavy-duty |

| Typical Applications | Standard 1500 trucks, V6/V8 cars | 6.0L Escalade, Denali, SS trucks |

| Real-World HP Limit | 400 hp | 450-500 hp |

Should You Upgrade to a 4L65E?

It depends on what you’re doing with your vehicle.

Upgrade if you’re:

- Running a 6.0L engine or heavily modified LS

- Towing heavy loads regularly

- Planning aggressive launches or performance driving

- Already rebuilding and can source 4L65E parts

Stick with a properly built 4L60E if you’re:

- Running a stock or mildly modified 4.8L/5.3L

- Daily driving without heavy loads

- Dealing with incompatible wiring harnesses or input shafts

- Working with a tight budget

The 4L65E represents GM’s final evolution of the four-speed automatic before jumping to the six-speed 6L80. It’s not a radical redesign—just strategic reinforcement of the weak points that plagued the 4L60E under high torque.

For the right application, it’s a solid upgrade that delivers real-world durability. Just make sure you match the input shaft, wiring harness, and torque converter to your specific engine and model year. Get those details wrong, and your “simple” transmission swap turns into a expensive headache.

The good news? If you’re swapping between 1999-2005 LS trucks, it’s genuinely straightforward. And if you can’t find a complete 4L65E, rebuilding your 4L60E with heavy-duty internals—five-pinion planets, hardened sun shell, upgraded clutch packs—gives you most of the benefits without the compatibility hassles.