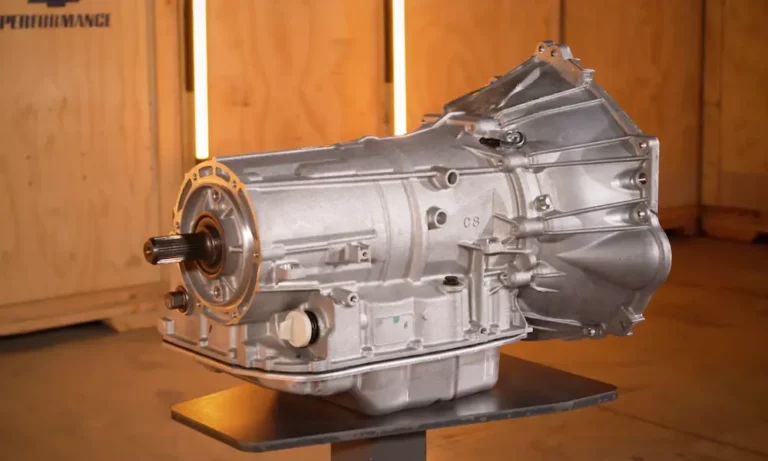

Wondering how long your GM 6L80 transmission will last? If you own a Silverado, Tahoe, Sierra, or any other GM vehicle with this transmission, you’re probably concerned about its reliability and longevity. I’ve gathered the facts about the 6L80’s expected lifespan, common problems, and how to maximize its service life to help you avoid costly repairs.

How Long Do 6L80 Transmissions Actually Last?

The GM 6L80 transmission typically lasts between 100,000 to 150,000 miles under normal driving conditions. Some owners report early failures while others see their transmissions exceeding 200,000 miles with proper care. The critical point seems to be around the 150,000-mile mark, where failure rates increase significantly.

The transmission’s lifespan largely depends on:

- Driving habits (towing, city vs. highway)

- Maintenance schedule

- Operating temperatures

- Factory torque converter issues

Most GM 6L80 transmissions follow this general timeline:

- 80,000-100,000 miles: Early warning signs appear

- 100,000-150,000 miles: Most failures occur in this range

- 150,000+ miles: High-risk zone for catastrophic failure

The Achilles’ Heel: Torque Converter Problems

The torque converter is undoubtedly the 6L80’s weak link. This component fails most frequently, usually between 100,000-200,000 miles, and often contaminates the entire transmission system with metal debris.

Why does this happen? The factory torque converter has fundamental design flaws:

- GM uses a one-size-fits-all converter across different vehicle weights and power levels

- The torque converter clutch is programmed to engage and slip in lower gears

- This programming causes excessive heat and premature wear

The most common symptom is the dreaded “torque converter shudder” – a vibration felt during acceleration above 18 mph that feels like you’re driving over rumble strips.

Warning Signs Your 6L80 Transmission Is Failing

Don’t ignore these red flags that indicate your transmission might be in trouble:

| Warning Sign | What It Means | When to Act |

|---|---|---|

| Torque converter shudder | Clutch material wearing out | Immediately |

| Metal debris in transmission pan | Internal component failure | Immediately |

| Burnt transmission fluid smell | Overheating issues | Within weeks |

| Hard or delayed shifting | Pressure or electric control issues | Within months |

| Check engine light with code P0741 | Torque converter clutch failure | Immediately |

| Transmission fluid temperature above 190°F | Cooling system inadequacy | Add external cooler |

These symptoms typically begin appearing between 80,000-100,000 miles. The earlier you address them, the better your chances of avoiding a complete transmission failure.

Major Issues That Kill 6L80 Transmissions

Beyond the torque converter, several design weaknesses plague the 6L80:

1. Overheating

The factory thermostat opens too late, causing the transmission to run hotter than ideal. Excessive heat is a transmission killer, breaking down fluid and accelerating wear on internal components.

2. Valve Body Wear

The pressure regulator valve bore wears out over time, affecting line pressure throughout the transmission. This leads to slipping, hard shifts, and eventually component failure.

3. Pump Failures

The transmission pump can fail prematurely, often because metal debris from a failed torque converter circulates through the system. When the pump goes, you’ll lose all hydraulic pressure – meaning no forward or reverse gears.

4. Slipping Gears

As internal clutches wear out, you’ll notice the transmission slipping, particularly when accelerating from a stop. This is often a sign that major components are failing.

How to Extend Your 6L80’s Life Expectancy

While the 6L80 has its issues, you can significantly improve its longevity with these preventative measures:

1. Frequent Fluid Changes

Forget GM’s 100,000-mile service interval – it’s too long. Change your transmission fluid every 30,000-50,000 miles instead. Fresh fluid provides better lubrication and cooling, dramatically extending component life.

2. Install an External Transmission Cooler

The factory cooling system is inadequate, especially if you tow or drive in hot climates. An aftermarket transmission cooler can lower operating temperatures by 20-30°F, potentially doubling your transmission’s lifespan.

3. Consider a Thermostat Bypass

The factory thermostat restricts coolant flow until the engine reaches operating temperature. Modifying this system to allow immediate coolant flow to the transmission helps prevent overheating during cold starts.

4. Torque Converter Programming Modifications

Professional tuning can disable torque converter lockup in the lower gears, reducing the wear that leads to converter failure. This modification alone can add years to your transmission’s life.

5. Upgrade to a Higher-Quality Torque Converter

If you’re having the transmission serviced, consider replacing the factory torque converter with an upgraded aftermarket version designed to handle more heat and stress.

Replacement and Repair Costs

If your 6L80 does fail, be prepared for significant repair costs:

| Repair Type | Cost Range (2024) | Notes |

|---|---|---|

| Complete rebuild | $4,000-$6,000 | Includes parts and labor |

| Remanufactured transmission | $4,300-$5,800 | Often includes warranty |

| Torque converter replacement | $600-$1,000 (plus labor) | Preventative measure |

| Labor costs | $800-$1,600 | 5-10 hours typically required |

The 6L80’s complex design makes it one of the more expensive transmissions to rebuild. Many shops recommend replacing the entire unit rather than attempting repairs, especially on high-mileage transmissions.

Is the 6L80 a Bad Transmission?

Despite its issues, the 6L80 isn’t inherently a bad transmission. Its 6-speed design can handle up to 440 lb-ft of torque, making it robust for most applications. The primary problem is the factory torque converter design and programming, which creates a cascade of issues.

Most transmission specialists agree that with proper maintenance and modifications, the 6L80 can provide reliable service. However, without intervention, the factory configuration makes it essentially a “time bomb” that will eventually require attention.

Real-World 6L80 Longevity Examples

Actual longevity varies widely among owners:

- Many Silverado and Sierra owners report failures between 100,000-140,000 miles

- Some lucky drivers see 200,000+ miles with regular maintenance

- Vehicles used for towing typically experience earlier failures (80,000-110,000 miles)

- Highway-driven vehicles with transmission coolers often reach 180,000+ miles

Make Your 6L80 Last: A Maintenance Schedule

Follow this schedule to maximize your transmission’s lifespan:

- Every 30,000 miles: Change transmission fluid and filter

- Every 60,000 miles: Inspect torque converter function for signs of shudder

- By 80,000 miles: Consider installing an external transmission cooler

- At first sign of shudder: Address torque converter issues immediately

The Bottom Line on 6L80 Transmissions

The GM 6L80 transmission has a mixed reliability record, with most units lasting between 100,000-150,000 miles. The torque converter is its main weakness, often failing and contaminating the entire system.

With proactive maintenance – especially frequent fluid changes and cooling system upgrades – you can extend your 6L80’s life considerably. If you’re buying a used GM vehicle with this transmission, look for one with documented transmission service and fewer than 100,000 miles for the best reliability prospects.

Remember: the 6L80 isn’t necessarily a ticking time bomb, but it does require more attention than GM’s maintenance schedule suggests. Take care of it properly, and it can provide many years of reliable service.