If you’re reading this, your GM truck or SUV probably just gave you that stomach-dropping shudder at 40 mph. Or maybe you’re stuck in limp mode on the side of the highway. The 6L80 transmission has a reputation—and not the good kind. This guide cuts through the noise to show you what’s actually failing, why it happens, and what you can do about it.

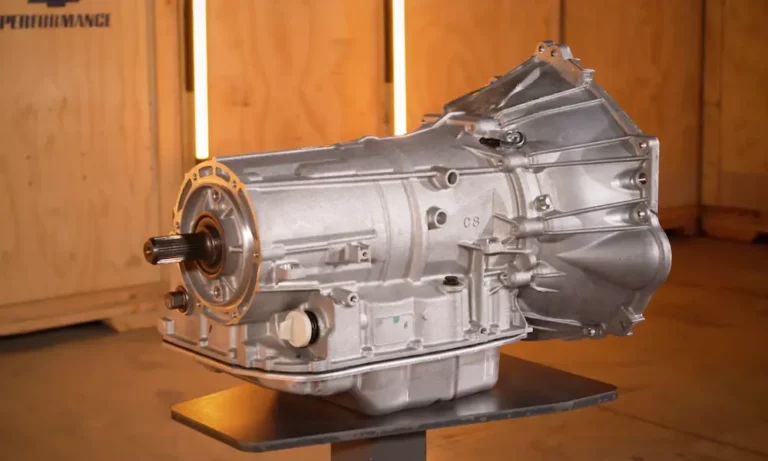

What Makes the 6L80 Different (And Why That Matters)

GM introduced the 6L80 in 2006 as a fundamental redesign. Unlike the older 4-speed units with bands and sprags, this six-speed uses a clutch-to-clutch architecture based on something called a Lepelletier gearset. Sounds fancy. In practice, it means every shift requires split-second timing controlled entirely by electronics submerged in your transmission fluid.

You’ll find this transmission in millions of vehicles:

- Silverado and Sierra trucks (2009-2018)

- Tahoe, Suburban, Yukon, and Escalade SUVs (2007-2020)

- Performance cars like the Corvette C6 and Camaro (2006-2015)

The 6L80 can handle serious power—up to 8,600 lbs gross weight and high-output V8 torque. When it works, it’s smooth and capable. When it doesn’t, you’re looking at a four-figure repair bill.

The Torque Converter Problem That Starts Everything

Here’s the brutal truth: most 6L80 transmission problems start with the torque converter clutch. This isn’t random—it’s baked into the design.

Why Your Torque Converter Is Self-Destructing

GM needed to meet fuel economy regulations. Their solution? Lock the torque converter as often as possible to eliminate slippage. But locking it creates a problem: when your V8 shuts off four cylinders (that’s Active Fuel Management or AFM), it vibrates like crazy.

So the engineers programmed a “regulated apply” strategy. Instead of fully locking, the torque converter clutch slips continuously—typically 20-50 RPM—using pulse-width modulation. This slip absorbs engine vibrations before they reach your seat.

It also slowly cooks the friction material to death.

The “Forbidden Glitter” Effect

The factory friction lining can’t handle constant thermal friction. Between 60,000 and 100,000 miles, it starts breaking down:

- The bonding agents degrade from heat

- The lining glazes over or flakes off in chunks

- Steel eventually grinds against steel

- Fine metal shavings contaminate your fluid

Mechanics call this debris “forbidden glitter”—and it’s a death sentence for your transmission. The contaminated fluid flows from the converter straight to your cooler, then back through the lubrication circuit. It hits critical components before the filter ever sees it.

How Metal Shavings Kill Your Transmission

Once that glitter enters your hydraulic system, you’re on borrowed time.

The Pump Wears Out

The 6L80 uses a variable-displacement vane pump with clearances measured in ten-thousandths of an inch. When metal particles act like industrial lapping compound, they:

- Embed in the soft aluminum pump housing

- Score the precision surfaces

- Destroy the hydraulic seal

- Kill line pressure at idle

You’ll notice delayed engagement into Drive or Reverse. The transmission might slip out of gear at stoplights. Listen for a whining or groaning noise from the front of the transmission—that’s cavitation.

The Valve Body Takes Damage

Your valve body is an aluminum casting with precision bores. The Pressure Regulator valve constantly oscillates to maintain system pressure. It’s the first victim of debris.

As the bore wears from contamination:

- Low pressure causes soft shifts and burnt clutches

- High pressure creates harsh, banging shifts that can crack internal parts

The aftermarket sells O-ringed valve kits from Sonnax that seal against worn bores. It’s cheaper than replacing the entire valve body.

The Electronic Brain That Lives in Hot Oil

Here’s a questionable design choice: GM mounted the Transmission Control Module inside the pan, submerged in transmission fluid. They call it the TEHCM (Transmission Electro-Hydraulic Control Module).

It’s exposed to extreme heat, vibration, and conductive debris. Predictably, it fails.

Pressure Switch Failures

The TEHCM uses pressure switches to verify hydraulic circuits are working. These switches have flexible laminate diaphragms that:

- Become brittle from heat cycles

- Crack or delaminate from the switch body

- Get caked with sludge from contaminated fluid

When a switch fails, you’ll see codes like:

- P0872 – Pressure Switch 3 Circuit Low

- P0877 – Pressure Switch 4 Circuit Low

- P0989 – Pressure Switch 5 Circuit Low

The transmission enters limp mode. You’re stuck in one gear with violent shifts and no power.

Solenoids Get Contaminated

The TEHCM houses electromagnetic solenoids that control hydraulic pressure. Metal dust from your failed torque converter is magnetic. It sticks to the solenoids.

When solenoids stick:

- Stuck off = loss of specific gears or RPM flares during shifts

- Stuck on = clutch bind-ups that can snap shafts

Common codes include P0796, P2714, and P2723—each indicating a different clutch pack failure.

The Temperature Controversy

Your 6L80 runs hot by design. Really hot. And that’s a problem.

The 190°F Strategy

From the factory, your transmission has a thermal bypass valve with a wax pellet thermostat. It keeps fluid circulating internally until it reaches 190°F. Only then does it send fluid to your external cooler.

Why? Thinner hot fluid reduces drag on internal components. That improves fuel economy by fractions of a percent—enough to help GM meet CAFE standards.

The penalty: you’re operating near the thermal degradation point of the fluid and seals. For every 18°F increase in temperature, oil oxidation doubles and fluid life gets cut in half. At 210°F, your transmission is cooking itself.

When the Bypass Valve Fails

Debris can jam the bypass valve in the “recirculate” position. When that happens, you lose all external cooling. Temperatures spike past 270°F. You’ll get code P0218 before total meltdown.

The Aftermarket Fix

Smart owners replace the factory bypass with a delete kit or low-temperature thermostat. Products from Superior Solutions (STL010) or PPE open at 150°F instead of 190°F.

Users report drops from 195-210°F down to 140-160°F. That’s huge for longevity.

Some argue running too cool (below 120°F) prevents proper lubrication. But in heavy-duty truck applications, the risk of overheating vastly outweighs running “too cool.” Most transmission rebuilders agree—cooler is better.

Hard Parts That Break

Beyond hydraulics and electronics, certain internal components have metallurgical flaws.

The 1-2-3-4 Apply Piston

This large cast aluminum piston handles power delivery in first through fourth gears. The factory casting quality is poor—prone to porosity and stress cracks.

Under high hydraulic pressure, hairline cracks develop near the seal grooves. Pressure bleeds off. The clutch can’t fully engage.

You’ll notice:

- Long delay from Park to Drive

- RPM flares during the 1-2 or 2-3 shift

The fix: rebuilders discard the factory part and install a billet aluminum piston from Sonnax or Circle D. No more porosity, no more cracks.

The 3-5-R Drum

This rotating drum can suffer from:

- Laser weld failures where the shaft attaches

- Premature bushing wear when lubrication pressure drops

Excessive play causes vibration and seal failure.

The Lawsuit You’re Probably Not Part Of

If you’ve seen headlines about “GM Transmission Class Action Lawsuits,” pay attention to the details.

The 8-Speed Cases (Not Your Problem)

The major lawsuits right now—Speerly v. General Motors and related cases—target the 8L90 and 8L45 8-speed transmissions from 2015-2019. These involve shudder from moisture absorption in the factory fluid.

In August 2024, the Sixth Circuit upheld class certification for these 8-speed cases, potentially covering 800,000 vehicles.

These certifications DO NOT cover the 6L80. Don’t get your hopes up.

What About 6L80 Litigation?

There have been attempts (like Strickland v. General Motors) to certify classes for 6L80/6L90 issues. But here’s the problem: most 6L80s fail between 80,000 and 120,000 miles.

GM successfully argues that’s normal wear-and-tear, not a manufacturing defect. Unlike the 8-speed fluid issue with a clear fix, the 6L80’s torque converter problem is harder to prove as a “defect.”

Bottom line: There’s no nationwide recall or settlement. Once your powertrain warranty expires (typically 5 years/60,000 miles), repairs are on your dime.

The TSB Confusion

TSB 18-NA-355 is for 8-speed transmissions. It prescribes a fluid exchange to Mobil 1 LV ATF HP to fix shudder.

Don’t waste your time applying this to a 6L80. The 8-speed shudder comes from fluid chemistry. Your 6L80 shudder comes from physical destruction of the clutch lining. Flushing won’t fix it.

PIP5337 is the GM bulletin that matters for your transmission. It explicitly states: if shudder is confirmed, replace the torque converter. Flush the cooler lines. Don’t mess around with half-measures.

How to Diagnose Your Problem

The Rumble Strip Test

This is your field test for torque converter clutch failure:

- Drive 30-60 mph in high gear (5th or 6th)

- Steady throttle, low RPM (1200-1600)

- Feel for rhythmic vibration through the seat

While the shudder is happening, lightly tap the brake with your left foot—just enough to trigger the brake lights.

If the shudder stops instantly, the torque converter clutch is the culprit. The TCM unlocks the converter when it sees brake application.

Check Your Fluid

Drop the pan and look at the magnet:

- Normal: Fine gray slime (friction dust)

- Terminal: Fuzzy metal shavings or visible silver chunks

If you see metal, don’t flush. Don’t drive. The transmission comes out for a rebuild.

Dark brown fluid means oxidation from heat. Burnt smell means slipping clutches. Neither is good.

Your Repair Options (And What They’ll Cost)

Option 1: The Band-Aid ($200-$400)

Flush the fluid and add a friction modifier like Lubegard Instant Shudder Fixx.

Reality check: If the friction lining is physically gone, this does nothing. If it’s just glazed, you might get 5,000-10,000 miles. Don’t count on it for long-term ownership.

Option 2: Converter Replacement Only ($1,200-$1,800)

Remove the transmission, replace the torque converter, flush the fluid.

The risk: If any debris has entered the pump or valve body, your new converter will fail shortly. This only works if you catch it extremely early and the pan is clean.

Option 3: GM Remanufactured Unit ($4,500-$5,500)

A GM Service Replacement Transmission Assembly comes with a 3-year/100,000-mile warranty.

The problem: These units are often rebuilt to factory specs. That means they contain the same design weaknesses that caused your first failure. You’re rolling the dice.

Option 4: The Bulletproof Rebuild ($4,000-$6,500)

A custom rebuild from a specialist shop using aftermarket upgrades. This is the best option for reliability.

What goes into a bulletproof 6L80:

| Component | Upgrade | Why It Matters |

|---|---|---|

| Torque Converter | Billet front cover, multi-disk HD clutch | Prevents ballooning and lining failure |

| Thermal Bypass | Delete kit or 150°F thermostat | Keeps fluid under 160°F |

| Pump Rotor | Billet steel rotor and slide | Resists debris wear, maintains pressure |

| 1-2-3-4 Piston | Billet aluminum (Sonnax/Circle D) | Eliminates cracking and pressure loss |

| TEHCM | New pressure switches and solenoid screens | Restores electronic reliability |

| Valve Body | Sonnax Zip Kit with O-ringed plugs | Seals worn bores |

This approach engineers out the factory defects. You’re not just fixing it—you’re making it better than new.

Prevention (If You Still Have Time)

If your 6L80 isn’t showing symptoms yet, you can extend its life significantly.

Do this:

- Disable AFM/DoD to reduce torque converter stress

- Install a thermal bypass delete or low-temp thermostat

- Change fluid every 40,000 miles (not the 100,000-mile “lifetime” GM claims)

- Add an auxiliary cooler if you tow regularly

Watch for early warning signs:

- Slight shudder at steady cruise (40-60 mph)

- Hesitation when shifting from Park to Drive

- Whining noise from the transmission

Catch it early, and you might get away with just a converter replacement. Wait too long, and you’re looking at a full rebuild.

The Bottom Line

The 6L80 isn’t a terrible transmission. It’s a compromised transmission—designed to meet fuel economy regulations at the expense of durability.

The torque converter clutch fails predictably. That failure creates contamination. The contamination destroys the pump, valve body, and electronics in sequence. It’s not bad luck. It’s the design.

Once failure begins, partial repairs rarely work. You can’t flush away physical damage. A comprehensive rebuild with billet upgrades is the only permanent fix.

If you’re past the point of prevention, find a transmission shop that specializes in 6L80 rebuilds and uses aftermarket hard parts. Ask specifically about billet torque converters, thermal bypass deletes, and upgraded pistons.

Don’t trust a shop that wants to “flush it and see what happens.” That’s how you pay twice.