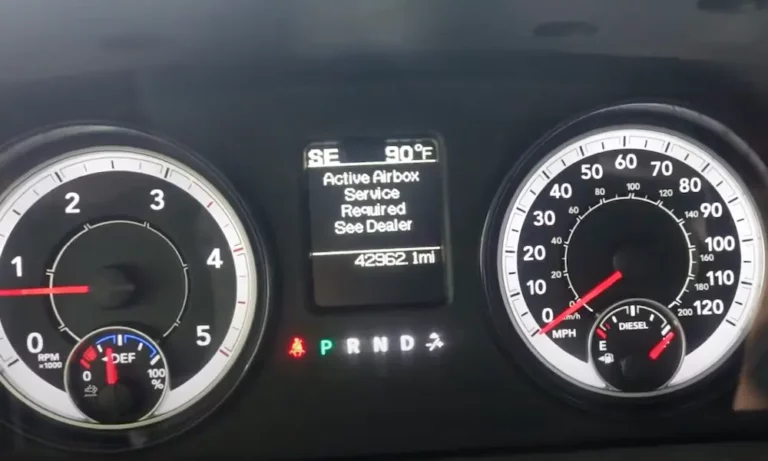

Ever seen that “Active Airbox Service Required” message light up on your Ram truck’s dashboard? Don’t panic. While it might sound serious, this warning doesn’t necessarily mean you’re facing an expensive repair. This specialized alert specifically targets issues with your Ram Cummins diesel’s air intake system—and often the fix is simpler than you might expect.

In this guide, we’ll break down everything you need to know about this common warning message. You’ll learn what the active airbox actually does, why the warning appears, and most importantly, how to diagnose and fix it yourself in many cases. Whether you’re a DIY mechanic or just want to understand the issue before heading to a shop, you’ll find practical solutions that could save you time and money.

What Is the Active Airbox System?

The active airbox in Ram diesel trucks isn’t just a simple air filter housing. It’s an intelligent system designed to optimize your engine’s performance across various driving conditions.

How It Works

At the heart of the system is a swing gate mechanism that controls airflow to your engine. During normal driving, this gate stays closed, directing air through the standard intake path. But when you need extra power—like when towing heavy loads or accelerating hard—the gate opens to increase airflow to your engine.

This dynamic system includes:

- A motorized actuator that controls the swing gate position

- A swing gate arm connected to the motor shaft

- Sensors that monitor airflow restriction

- Integration with your truck’s electronic control modules

The system works alongside your air filter to ensure clean air reaches the engine while maintaining appropriate air pressure and volume. When everything’s functioning correctly, you get optimal performance and efficiency without ever thinking about it.

Why It Matters for Performance

This isn’t just a fancy feature—it directly impacts how your truck performs. The active airbox helps your Cummins diesel deliver:

- Better response during heavy acceleration

- Improved power when towing or hauling

- Optimized air intake across various driving conditions

- Protection from unnecessary engine strain

When the system detects an issue, it triggers the “Active Airbox Service Required” message to prevent potential performance problems or damage.

Common Causes of Active Airbox Warning Messages

When that warning message appears, several issues could be triggering it. Here are the most common culprits:

Installation Problems

Many active airbox issues stem from improper installation after maintenance:

- Incorrect positioning of the air box, preventing it from sitting flush

- Improper alignment where the air box pegs don’t correctly seat in the battery tray holes

- The swing gate making contact with the air filter due to misalignment

- Swing gate arm not correctly installed on the motor shaft

These problems often appear after someone has serviced the air filter or removed components during other maintenance work.

Physical Obstructions

Your active airbox can become obstructed in various ways:

- Foreign objects entering the intake system

- Debris buildup restricting movement of the swing gate

- Damage to the flexible tube connecting the intake box to the fenderwell

- In one documented case, a bird had built a nest in the air intake of a Ram truck that had been parked for an extended period

These physical barriers prevent normal operation and trigger the warning message.

Component Damage

Physical damage to airbox components will also trigger warnings:

- Stripped swing gate arm from attempts to manually rotate it

- Damage to the motor shaft connection

- Damaged actuator motor that can’t properly control the swing gate

- Crushed or damaged flexible intake tube

Electrical Issues

Don’t overlook potential electrical problems:

- Disconnected sensor wires

- Damaged Mass Air Flow (MAF) sensor

- Corroded electrical connectors affecting the actuator motor

- Problems with the Intake Air Temperature (IAT) sensor

These electrical issues can prevent proper system operation or cause incorrect readings that trigger the warning.

How to Diagnose Active Airbox Issues

Before you can fix the problem, you need to identify exactly what’s wrong. Here’s a systematic approach to diagnosing active airbox issues:

Visual Inspection

Start with a thorough visual check:

- Open the air box and examine the swing gate mechanism

- Check for obvious obstructions or foreign objects

- Verify the arm is properly attached to the motor shaft

- Ensure the air filter isn’t excessively contaminated

- Look for proper positioning of all components

- Check that the air box sits flush with properly seated pegs

This simple inspection often reveals the problem immediately.

Using Diagnostic Tools

For deeper diagnosis:

- Connect a scan tool to the OBD-II port to identify specific fault codes

- Look for code P2280, which indicates air flow restriction (commonly associated with active airbox issues)

- Use advanced scan tools to perform calibration tests of the active airbox functionality

- Monitor Mass Air Flow (MAF) sensor readings during engine operation

These electronic diagnostics can confirm whether mechanical issues are present and if repairs have resolved underlying problems.

Understanding Warning Patterns

The behavior of the warning message provides important clues:

- Constant warning messages typically indicate persistent mechanical issues

- Intermittent warnings often appear during conditions that trigger the swing gate to open

- Warnings that disappear after driving suggest partial obstructions

- Messages appearing alongside “Service Air Filter” warnings may indicate related but separate issues

| Warning Behavior | Likely Cause | Suggested Action |

|---|---|---|

| Constant warning | Disconnected component or severe obstruction | Inspection of physical connections |

| Appears during acceleration | Swing gate operation issue | Check actuator function |

| Disappears after driving | Intermittent connection or partial obstruction | Thorough cleaning and connection check |

| Appears with other warnings | Multiple related issues | Comprehensive system inspection |

Step-by-Step Repair Procedures

Once you’ve identified the issue, follow these repair procedures based on the specific problem:

Fixing Installation Issues

If improper installation is the culprit:

- Remove the air box assembly

- Ensure the air filter is correctly positioned

- Verify the swing gate arm properly attaches to the motor shaft

- Position the air box so it sits flush with its mounting surface

- Confirm the pegs on the bottom correctly fit in the battery tray holes

- Check that there’s adequate clearance between the swing arm dam and filter

Proper positioning prevents the swing gate from contacting the air filter and ensures all components move freely.

Clearing Obstructions

When obstructions are the problem:

- Partially disassemble the air intake system if needed

- Remove all foreign material, nest debris, or other obstructions

- Clean all components thoroughly

- Test the swing gate through its full range of motion

- Verify no obstructions remain before reassembling

Take extra care with the flexible tube connecting to the fenderwell, as damage here is easily overlooked.

Replacing Damaged Components

If components are damaged:

- Replace any stripped or damaged swing gate arms

- Install a new actuator motor if the original has failed

- Replace damaged connecting tubes

- Follow manufacturer specifications for all replacement parts

- Be aware that some components require specific initialization procedures

Note that for certain severe damage, the motor might need to be sent to the manufacturer for proper reset procedures.

Verification and Reset Process

After repairs, always verify the fix:

- Use a scan tool to perform calibration tests of the system

- Clear any stored fault codes

- Test drive under various operating conditions

- Pay special attention during heavy acceleration or load conditions

- Drive 30-50 miles to allow the system to complete self-diagnostic routines

- Confirm the warning message doesn’t reappear

If the warning persists after these steps, you may need further diagnosis to identify additional issues.

Preventative Maintenance Tips

Prevent future problems with these maintenance practices:

Regular Inspection Routine

Make these checks part of your regular maintenance:

- Visually examine the air box assembly during oil changes

- Check for damage, misalignment, or obstructions

- Ensure the swing gate moves freely

- Verify all connections remain secure

- Look for signs of moisture or debris accumulation

These quick checks take just minutes but can prevent bigger problems.

Proper Service Techniques

When servicing the air filter:

- Follow reassembly procedures carefully

- Properly seat the air filter with clearance from the swing gate

- Correctly position the air box on its mounting points

- Avoid manually manipulating the swing gate

- Let the electronic controls operate the gate naturally

These careful practices during routine maintenance prevent many common issues.

| Maintenance Activity | Frequency | Key Focus Areas |

|---|---|---|

| Visual inspection | Every oil change | Swing gate movement, obstructions, connections |

| Air filter change | Per manufacturer recommendation | Proper reassembly, clearance, alignment |

| Scan for codes | Every 6-12 months | Look for pending issues before failures occur |

| Intake tube check | Twice yearly | Damage, crushed sections, secure connections |

Special Considerations

For trucks in specific situations:

- If storing your truck for extended periods, consider protective covers for intake openings

- In dusty environments, inspect and clean the system more frequently

- For heavy towing applications, monitor performance closely for early warning signs

- Be cautious with aftermarket air filters—ensure they’re compatible with the active airbox system

- Consider environmental factors—high humidity and extreme temperatures can accelerate wear

By implementing these preventative measures, you’ll reduce the likelihood of seeing that “Active Airbox Service Required” message light up your dashboard.

Understanding Long-Term Implications

Addressing active airbox issues promptly does more than just clear a warning message—it protects your truck’s performance and longevity:

- Unresolved airflow issues can reduce engine efficiency

- Restricted air intake may increase fuel consumption

- Poor air management can accelerate filter contamination

- Ignoring warnings could lead to more expensive repairs later

- Maintaining proper airflow ensures optimal combustion and power

The active airbox system represents the increasing integration of mechanical and electronic components in modern diesel engines. While this technology delivers significant performance benefits, it requires informed maintenance practices to ensure long-term reliability.

By understanding how your Ram’s active airbox functions, recognizing common failure points, and implementing appropriate diagnostic and repair procedures, you can enjoy the performance advantages of your Cummins diesel while minimizing downtime and repair costs.

Remember that this sophisticated system isn’t just about filtering air—it’s actively managing your engine’s breathing to deliver the power and efficiency you expect from your Ram diesel truck. With proper care, it will continue to do its job without drawing attention to itself, leaving you free to enjoy the ride.