Ever tried to fill up your car only to have the pump constantly clicking off? Or maybe you’ve noticed a strong gas smell around your vehicle? If you’re driving a vehicle with a capless fuel system, these frustrating issues might be more common than you’d think.

Modern capless fuel systems were designed to make life easier by eliminating the traditional gas cap. But as many drivers have discovered, this convenient feature comes with its own set of headaches. Let’s dive into the most common capless gas tank problems and the practical fixes you need to know.

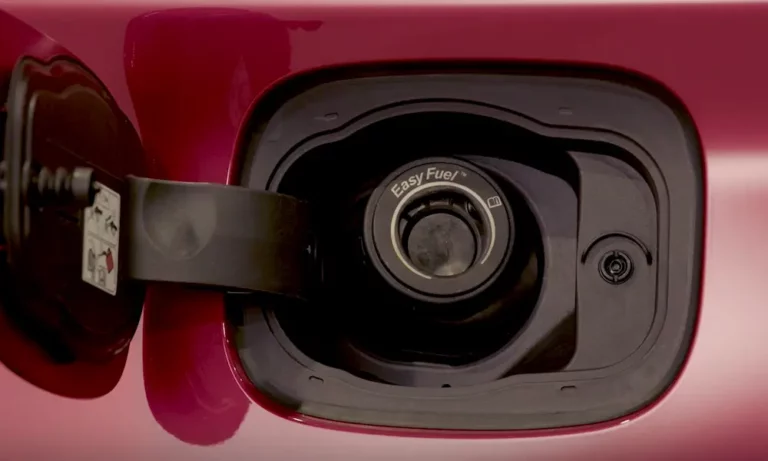

What Exactly Is a Capless Fuel System?

A capless fuel system replaces the traditional screw-on gas cap with a spring-loaded flap inside the filler neck. When you insert the fuel nozzle, it pushes open the flap, and when you remove it, the flap automatically closes and seals.

Car manufacturers introduced these systems to help reduce emissions and eliminate the “check engine” lights caused by improperly tightened gas caps. They’re standard on many Ford, Honda, GM, and other vehicles manufactured since around 2010.

Problem 1: The Pump Keeps Clicking Off During Refueling

Nothing’s more annoying than standing at the pump for 15 minutes trying to fill your tank with tiny trigger pulls.

Why This Happens

When you can’t fill your tank without the pump constantly clicking off, the problem usually stems from your vehicle’s evaporative emission (EVAP) system. The air displaced by incoming fuel can’t escape fast enough, creating back pressure that triggers the pump’s auto-shutoff.

How to Fix It

- Check for damaged or pinched vent hoses leading from your gas tank to the charcoal canister

- Inspect the purge valve for clogs or malfunction

- Clean the vent lines with compressed air (if accessible)

For severe cases, you may need a mechanic to check the entire EVAP system.

Problem 2: Check Engine Light with EVAP Leak Codes

Getting a P0456 code (Evaporative Emission System Small Leak Detected)? Your capless system might be the culprit.

Why This Happens

Dirt and debris can accumulate around and inside the capless flap mechanism, preventing the O-ring seal from creating a proper vapor-tight seal. This lets fuel vapors escape, triggering the check engine light.

How to Fix It

According to BobIsTheOilGuy forums, a simple cleaning can often resolve this issue:

- Spray denatured alcohol or electronics cleaner around the filler neck

- Use your emergency funnel to activate the flap mechanism

- Clean any visible debris from the sealing surfaces

- Apply a light coat of non-petroleum lubricant to the O-ring seal

| EVAP Code | Meaning | Likely Capless System Cause |

|---|---|---|

| P0455 | Large EVAP leak detected | Damaged flap or seal |

| P0456 | Small EVAP leak detected | Dirty or partially sealed flap |

| P0457 | Fuel cap loose/missing | Faulty capless seal mechanism |

Problem 3: Stuck or Binding Flap Mechanism

Can’t even get the nozzle into the tank? Your capless system’s flap might be stuck.

Why This Happens

The spring-loaded flap inside the filler neck can become damaged, frozen, or clogged with road debris. This is especially common in vehicles with low-mounted filler necks that get exposed to road grime and weather elements.

How to Fix It

For a frozen flap, gently warming the area might help. For mechanical binding:

- Locate your emergency fuel funnel (usually in the trunk with the spare tire)

- Insert it fully to manually activate the flap mechanism

- Inspect for visible damage to the hinge or spring

Some owners have successfully repaired broken clips or springs, as shown in this Dodge Durango forum, but for complete failures, the entire filler neck assembly usually needs replacement.

Problem 4: Can’t Use a Gas Can in Emergencies

Many drivers discover this problem at the worst possible time—when they’re stranded and trying to add emergency fuel.

Why This Happens

Capless systems include anti-siphon baffles and specialized sealing mechanisms that only work with standard gas pump nozzles or the manufacturer’s emergency funnel.

How to Fix It

Always keep your emergency funnel in your vehicle! If you’ve lost it:

- Purchase a replacement from your dealer (usually $10-20)

- In a true emergency, carefully use a long, narrow funnel that can reach and depress the flap

- Make sure to insert any funnel completely before adding fuel

The funnel that came with your vehicle is specifically designed to open the capless system without triggering leak detection systems.

Problem 5: Fuel Odors and Leakage

Notice a strong gas smell after refueling or small drops of fuel around the filler door? Your capless system may be failing to seal properly.

Why This Happens

Without a traditional cap, the sealing responsibility falls entirely on the internal flap mechanism. If the O-ring deteriorates or debris prevents proper sealing, vapors and even liquid fuel can escape.

How to Fix It

- Clean the filler neck area thoroughly

- Check for damage to the sealing surfaces

- Avoid “topping off” past the first automatic shut-off click

- For persistent odors, the O-ring seal might need replacement

This YouTube video demonstrates how some capless systems can retain fuel in the neck area, leading to odors and potential small leaks.

Problem 6: Damage From Using the Wrong Nozzle

Using diesel pumps (even accidentally) or non-standard nozzles can damage capless systems.

Why This Happens

Capless systems are calibrated for standard gasoline nozzle diameters. Diesel nozzles are larger and can damage the internal flap mechanism if forced. Some older or non-standard gas pumps may also have nozzles that don’t properly activate the flap.

How to Fix It

Prevention is key:

- Double-check that you’re using the correct fuel type

- For non-standard pumps, use your emergency funnel

- If damage occurs, inspect for broken components and have the system checked by a professional

Problem 7: Problems After Car Washes or Heavy Rain

Some drivers report issues with their capless systems after their vehicles have been exposed to high-pressure water.

Why This Happens

Water can enter the filler neck area during car washes or heavy rain, potentially causing:

- Corrosion to the flap mechanism

- Freezing in cold weather

- Electrical issues with nearby components

How to Fix It

- After washing your car, open the fuel door and dry the area thoroughly

- If water freezes in the mechanism, gently warm the area

- Consider applying a light coating of water-displacing lubricant around (not inside) the filler neck

Preventive Maintenance for Capless Fuel Systems

Keep your capless system working properly with these maintenance tips:

- Clean the filler neck area regularly—about once every oil change

- Keep your emergency funnel in your vehicle at all times

- Avoid “topping off” your tank past the first click

- During routine maintenance, have your mechanic check the EVAP system and vent lines

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Clean filler neck | Every 3-6 months | Prevents debris buildup |

| Inspect for damage | During routine service | Catches issues early |

| Check emergency funnel | Annually | Ensures it’s available when needed |

| EVAP system check | With “check engine” lights | Prevents false codes |

Are Capless Systems Worth the Trouble?

Despite these issues, capless fuel systems do offer benefits:

- Convenience of not handling a gas cap

- Reduced emissions when working properly

- No more “check engine” lights from loose caps

- Clean hands during refueling

However, the trade-off is dealing with potentially more complex problems when they do occur.

If you’re experiencing persistent issues with your capless system, discuss options with your dealer. Some manufacturers have released updated parts to address common problems with earlier designs.

By understanding these common capless gas tank problems and their solutions, you can avoid much of the frustration that comes with this supposedly “convenient” feature.