Ever wondered why your Chevy engine sometimes feels different while cruising down the highway? That subtle change in engine sound and feel is likely cylinder deactivation at work. This fuel-saving technology has evolved significantly over the years, but it’s also generated plenty of controversy among Chevrolet owners.

What Is Cylinder Deactivation in Chevy Engines?

Cylinder deactivation is a fuel-saving technology that temporarily shuts down a portion of your engine’s cylinders when full power isn’t needed. Chevrolet uses two main versions of this technology: Active Fuel Management (AFM) and the newer Dynamic Fuel Management (DFM).

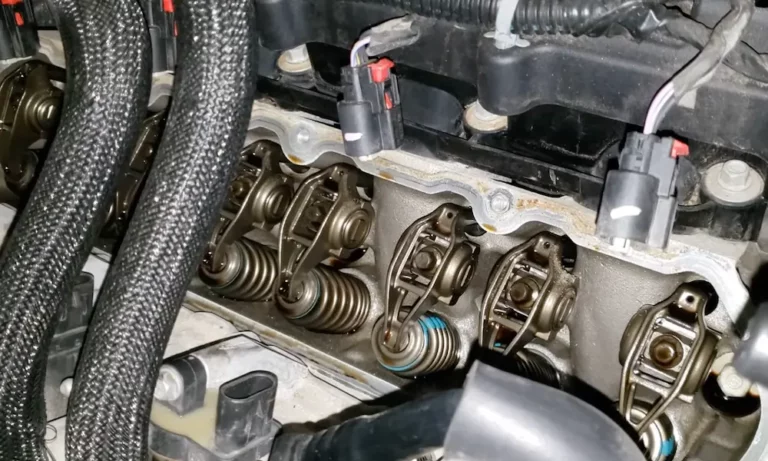

When you’re cruising at steady speeds or driving under light loads, your engine doesn’t need all cylinders firing. The system deactivates some cylinders by preventing their intake valves from opening, effectively turning your V8 into a V4 (or your V6 into a V3) during these low-demand situations.

The Evolution: From AFM to DFM

Active Fuel Management (AFM)

Introduced in 2005, AFM represented Chevy’s first successful implementation of cylinder deactivation technology. This system operates in just two modes:

- Full cylinder operation (all cylinders working)

- Reduced cylinder operation (half the cylinders deactivated)

For example, in a 5.3L V8 engine, AFM switches between all eight cylinders and just four cylinders depending on driving conditions. The system uses special hydraulic lifters and an oil control manifold to deactivate cylinders when needed.

Dynamic Fuel Management (DFM)

In 2019, Chevrolet introduced DFM, a more advanced system that offers 17 different cylinder patterns instead of just two. This means your engine can run on anywhere from one to all eight cylinders, constantly adapting to driving conditions.

The DFM system makes decisions about 80 times per second, providing more precise control and better fuel economy than traditional AFM.

Chevy Models With Cylinder Deactivation

| Technology | Years | Common Chevy Models | Engines |

|---|---|---|---|

| AFM | 2005-2018 | Silverado, Tahoe, Suburban, Camaro | 4.3L V6, 5.3L V8, 6.0L V8, 6.2L V8 |

| DFM | 2019-Present | Silverado, Tahoe, Suburban, Camaro | 5.3L V8, 6.2L V8 |

How AFM and DFM Actually Work

The Technical Side of AFM

AFM relies on special switching valve lifters that can be deactivated by redirecting oil pressure. Here’s the process:

- The Engine Control Module (ECM) detects light-load driving conditions

- The ECM sends a signal to solenoids in the Lifter Oil Manifold Assembly (LOMA)

- The solenoids redirect oil pressure to collapse specific valve lifters

- With lifters collapsed, valves don’t open, and those cylinders stop firing

- When power demands increase, the system immediately reactivates all cylinders

DFM’s Advanced Approach

DFM uses the same basic principles but with much more sophisticated control. Instead of just two modes, the DFM system can:

- Activate or deactivate any cylinder at any time

- Utilize 17 different firing patterns

- Recalculate the optimal pattern 80 times per second

- Consider factors beyond just fuel economy, including vibration and torque

Both systems are designed to work seamlessly, with drivers ideally not noticing the transitions between modes.

The Real Benefits of Chevy’s Cylinder Deactivation

Fuel Economy Improvements

The primary advantage of cylinder deactivation is improved fuel economy without sacrificing engine size or power. According to Chevrolet’s own data, AFM improves fuel economy by 5-7% under typical driving conditions.

DFM takes this even further, with efficiency improvements up to 15% compared to engines without cylinder deactivation. This translates to tangible savings at the pump, especially for trucks and SUVs with larger engines.

Performance When You Need It

Unlike downsized engines that might struggle under heavy loads, cylinder deactivation gives you the best of both worlds:

- Full power when accelerating or towing

- Improved efficiency when cruising

This means your 6.2L V8 Silverado can tow heavy loads up steep hills with all cylinders firing, then seamlessly switch to running on fewer cylinders when cruising on flat highways.

Reduced Emissions

By improving fuel efficiency, cylinder deactivation also helps reduce carbon emissions. This has become increasingly important as manufacturers work to meet stricter environmental regulations without sacrificing the power customers demand.

The Downsides: Common Problems With Chevy’s Cylinder Deactivation

Despite the benefits, many Chevy owners have experienced issues with cylinder deactivation systems. These problems have led to a thriving aftermarket for devices that disable these systems.

Lifter Failures

The most common and serious problem is lifter failure. The specialized switching lifters used in AFM/DFM systems can wear prematurely, leading to:

- Ticking or knocking sounds

- Misfires and rough running

- Engine damage if not addressed quickly

According to various forums and technical bulletins, these failures seem more common in vehicles that spend significant time in cylinder deactivation mode, particularly during highway driving.

Oil Consumption Issues

Some owners report increased oil consumption in engines with cylinder deactivation. This appears to be related to oil passing by the rings of deactivated cylinders or issues with valve seals. The National Highway Traffic Safety Administration has documented related technical service bulletins from GM addressing excessive oil consumption.

Vibration and NVH (Noise, Vibration, Harshness)

Earlier AFM systems sometimes created noticeable vibrations when running in four-cylinder mode. While DFM has improved this significantly with its flexible cylinder patterns and a centrifugal pendulum absorber in the torque converter, some drivers still report being able to feel when the system activates.

Solutions: How to Disable Cylinder Deactivation

Given the potential issues, many Chevy owners look for ways to disable cylinder deactivation. There are several approaches, ranging from simple plug-in devices to complete mechanical overhauls.

OBD-II Port Disablers

The simplest and most reversible solution is an OBD-II port disabler like the Range Technology AFM/DFM Disabler. These devices:

- Plug into your diagnostic port

- Trick the ECM into keeping all cylinders active

- Can be removed at any time

The downside is that they must remain plugged in to work, and they will reduce your fuel economy.

- Leaves no trace. Unplug it to return to factory settings

- Range AFM/DFM Disabler keeps you in full power 100% of the time.

- Simply plug into your onboard OBD-II port and it instantly begins working to eliminate the AFM system.

- The power and control you need in any situation.

ECM Tuning

A more permanent software solution involves reprogramming your engine’s computer:

- Custom tuning using tools like HP Tuners or DiabloSport

- Permanently disables AFM/DFM until changed back

- Often improves performance in other areas too

- Typically costs $300-600 including the tuner

This approach doesn’t address any mechanical components but prevents the system from activating.

No products found.

AFM/DFM Delete Kits

For those concerned about long-term reliability, mechanical delete kits replace the specialized lifters with conventional ones:

- Replace all switching lifters with standard lifters

- Remove the Lifter Oil Manifold Assembly (LOMA)

- Install a valley plate in place of the LOMA

- Requires ECM reprogramming to prevent check engine lights

- Costs $2,000-4,000 installed

This is the most comprehensive solution but also the most expensive and labor-intensive. Companies like ProMar Engine offer complete AFM/DFM delete services.

The L9 Shift Trick for DFM Vehicles

A little-known method for temporarily disabling DFM in newer Chevys was discovered by owners and reported by GM Authority:

- Use the manual shift mode to select “L9” gear (limits the transmission to 9th gear)

- This tricks the system into keeping DFM inactive

- Works until you shift out of L9 or restart the vehicle

- Costs nothing but reduces efficiency

This method provides a free way to temporarily disable DFM during highway driving without permanent modifications.

How to Tell if Your Cylinder Deactivation Is Working

If you’re curious whether your Chevy’s cylinder deactivation system is currently active, there are several ways to check:

Dashboard Indicators

Some Chevy models display a small “V4” or “ECO” indicator on the dashboard when running in reduced-cylinder mode. Check your instrument cluster when cruising at steady highway speeds.

Sound and Feel Changes

During cylinder deactivation, your engine’s sound typically changes slightly:

- Deeper, more hollow sound

- Slight change in engine vibration

- Often occurs when maintaining steady speeds between 40-65 mph

OBD-II Data

For the technically inclined, you can use an OBD-II scanner with live data capabilities to monitor:

- Mode status (many scanners will show AFM/DFM status)

- Fuel trim changes that occur during cylinder deactivation

- Individual cylinder contribution

Weighing Your Options: Should You Keep or Disable?

Deciding whether to keep or disable your Chevy’s cylinder deactivation system depends on your priorities:

Keep Cylinder Deactivation If:

- Fuel economy is your top priority

- Your driving involves lots of steady-speed cruising

- Your vehicle is under warranty

- You haven’t experienced any related issues

Consider Disabling If:

- You’ve already had AFM/DFM-related repairs

- You plan to keep your vehicle well beyond the warranty period

- Your driving involves towing or high-load situations

- You prefer reliability over maximum fuel economy

Maintenance Tips for AFM/DFM Equipped Chevys

If you decide to keep your cylinder deactivation system active, these maintenance practices can help prevent problems:

Regular Oil Changes

- Use the manufacturer recommended oil weight (typically 0W-20 or 5W-30)

- Consider shorter oil change intervals (5,000 miles instead of 7,500)

- Always use high-quality oil that meets GM’s dexos specifications

Avoid Extended Idling

Long periods of idling can be particularly hard on AFM/DFM systems. Whenever possible, shut the engine off rather than letting it idle for extended periods.

Drive Varied Routes

Mixing up your driving pattern helps ensure all cylinders get regular use. If you primarily drive highway miles, consider occasionally taking routes that involve more varied speeds and loads.

The Future of Cylinder Deactivation at Chevrolet

Despite the issues some owners have experienced, cylinder deactivation continues to be an important technology for Chevrolet as fuel economy standards tighten. Future developments are likely to include:

- Further refinement of DFM technology

- Integration with mild hybrid systems

- Potential migration to turbocharged engines

- Greater emphasis on smooth transitions between modes

As electrification increases, cylinder deactivation will likely serve as a bridge technology until full electric vehicles become the norm.

Making the Best Choice for Your Chevy

Cylinder deactivation represents an impressive engineering achievement that delivers real fuel savings, but it’s not without compromises. By understanding how Chevy’s AFM and DFM systems work, you can make informed decisions about whether to keep, modify, or disable this technology in your vehicle.

Whether you choose to embrace the efficiency benefits or prioritize long-term reliability through modification, the key is making a choice based on your specific needs, driving habits, and how long you plan to keep your Chevy.