You bought a Wrangler because it’s built to last. But here’s the thing: even the toughest vehicles need the right care at the right time. Skip the wrong service, and you’re staring down a five-figure repair bill. This guide cuts through the BS and shows you exactly when to wrench, what to watch for, and which fluids actually matter for your specific engine.

Why Your Jeep Wrangler Service Schedule Is Different

Your Wrangler isn’t a sedan. It’s a body-on-frame truck with solid axles and enough aerodynamic drag to make a brick jealous. Even highway cruising puts more stress on your engine than you’d think.

Here’s what makes the Jeep Wrangler service schedule unique: Jeep defines “severe duty” as towing, off-roading, dusty conditions, or frequent short trips. But that boxy shape means your engine works harder at highway speeds than most cars do at the same speed. Translation? You’re probably in the severe duty category even if you think you’re not.

Following the “normal” schedule is tempting. It’s easier, cheaper, and the manual says it’s fine. But engineers who build these things recommend tighter intervals for a reason. Well-maintained Wranglers hold their value better—documented service history can boost resale by 15%.

The Oil Change Schedule That Actually Protects Your Engine

Oil changes aren’t just about keeping things slippery. They’re about protecting expensive parts from self-destructing.

Know Your Engine, Know Your Oil

You can’t just grab any oil off the shelf. Your Wrangler’s engine determines what goes in the crankcase:

3.6L Pentastar V6: Needs 0W-20 synthetic meeting MS-6395 spec. The newer JL models dropped from 5W-20 to save fuel, but that thinner oil shears faster under pressure. Watch for the notorious oil cooler housing leak—it sits in the valley of the engine and cracks from heat cycling.

2.0L Turbocharged Engine: Requires 5W-30 synthetic (MS-13340). Don’t mess around here. That turbo spins over 150,000 RPM and runs hotter than your average V6. Wrong oil means dead turbo bearings.

3.0L EcoDiesel: Demands 5W-40 full synthetic (MS-12991). Diesel soot is brutal on oil, and if you’re running biodiesel blends (B5-B20), you’re fighting fuel dilution that won’t evaporate out of the crankcase.

How Often to Change Oil

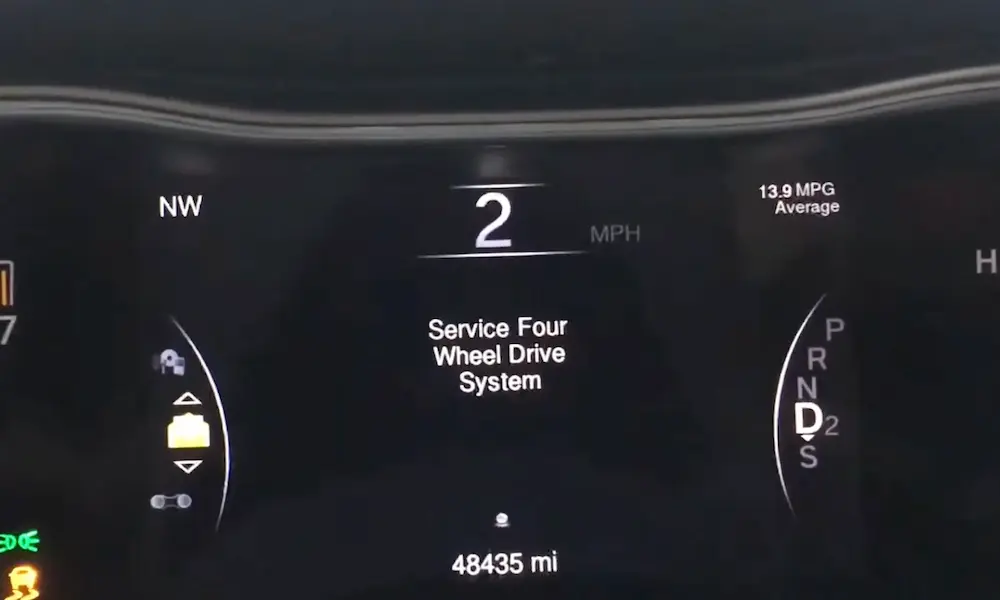

The dash might say you’ve got miles to go, but that Intelligent Oil Life Monitor doesn’t know everything. It can’t see that you’re driving a flying brick down the highway.

Maximum interval: 10,000 miles or 12 months (whichever comes first)

Smart interval: 5,000 to 7,500 miles for most drivers

EcoDiesel with B20: Cap it at 8,000 miles or 6 months

If you’ve got a 4xe, pay attention to something weird called Fuel Oil Refresh Mode (FORM). Your gas engine might start cold, run briefly, then shut off before warming up. That means unburned fuel and moisture contaminate your oil. Drive mostly electric with frequent cold starts? Change oil every 4,000 miles.

The 4xe Hybrid Schedule Nobody Tells You About

The Wrangler 4xe isn’t just a Wrangler with a battery. It’s got three separate cooling systems and maintenance needs that’ll surprise you.

The 30,000-Mile Spark Plug Rule

Here’s something that catches 4xe owners off guard: spark plugs at 30,000 miles. Not 60k or 100k like other engines—30k, period.

Why? Your 2.0L engine sits cold in Minnesota at -10°F, then gets slammed to full boost when you merge onto the highway with a dead battery. That thermal shock murders spark plugs. Skip this service and you’re looking at misfires, catalyst damage, or worse.

Standard 2.0L engines run 60,000 to 100,000 miles on plugs. The 4xe cuts that in half.

Three Cooling Systems You Need to Monitor

The 4xe has separate cooling loops for the engine, turbo intercooler, and high-voltage components. That third loop (the HV system) cools your battery pack, inverter, and onboard charger.

Check the HV coolant reservoir at every oil change. If the level drops, you’ve got a leak somewhere inside the battery pack—that’s a safety issue, not just a repair bill.

Watch for code P0C74 (Motor Electronics Coolant Pump B). This electric pump pushes coolant through the HV loop. When it fails, your electric mode dies and the check engine light comes on. Technical service bulletins show coolant leaks at water pump inlet tube fasteners on the 2.0L engine.

Use the Right Coolant or Pay

Your JL uses OAT (Organic Additive Technology) coolant, spec MS-90032. It’s purple but might look reddish-orange over time.

Don’t mix it with HOAT coolant (MS-9769) from older Chryslers (2012 and earlier). Mix them and you get gel that clogs everything—radiator, heater core, and those tiny battery cooling channels in the 4xe.

Color isn’t reliable for identifying coolant. Check the spec number on the bottle.

EcoDiesel Maintenance: Where Things Get Serious

The 3.0L EcoDiesel offers killer torque and range, but its fuel system doesn’t tolerate shortcuts.

The Fuel Filter Schedule That Prevents Disaster

Your high-pressure fuel pump (the CP4) uses diesel for lubrication. When it fails, metal shavings contaminate the entire fuel system—injectors, rails, tank, everything.

Jeep issued recall Z46/01A for 2020–2023 models to replace vulnerable pumps. But the fix isn’t just hardware—it’s maintenance.

Fuel filter changes: Every 10,000 miles (with each oil change)

With B20 biodiesel: Every 8,000 miles

Biodiesel acts like a solvent, stripping deposits from your tank and clogging the filter. It also attracts water, which is death for the CP4 pump.

Drain the Water Separator

Water kills fuel pumps. Your fuel filter housing has a water separator that needs draining at every oil change (or immediately when the “Water in Fuel” light pops on).

Access is through the frame rail. Attach a drain hose to the nipple to keep fuel off the driveshaft.

DEF Consumption Isn’t Consistent

Your Selective Catalytic Reduction system uses Diesel Exhaust Fluid to cut NOx emissions. The tank lasts about 10,000 miles under normal driving, but towing heavy loads triples consumption. You might drain the tank in 3,000 to 4,000 miles.

Don’t top off the DEF tank 100% in winter. DEF freezes at 12°F. The tank has a heater, but leave expansion room to avoid cracking the reservoir.

Transmission and Transfer Case: When “Lifetime” Isn’t

Jeep calls the ZF 8-speed transmission fluid “lifetime fill.” ZF (who built it) says change it every 60,000 to 80,000 miles.

The Fluid Your Transmission Actually Needs

This isn’t ATF+4 territory. The 8HP75 requires Mopar 8 & 9 Speed ATF (Part #68218925AA) or ZF Lifeguard 8.

Use ATF+4 and you’ll have shift problems immediately. The transmission pan includes an integrated filter—you replace the whole pan assembly during service.

Transfer Case Fluids: Two Systems, One Fluid

Your transfer case type determines service intervals, not just fluid type.

| Transfer Case | Type | Fluid | Change Interval |

|---|---|---|---|

| NV241/NV241OR | Part-Time (Command-Trac/Rock-Trac) | ATF+4 | 60k normal / 30k severe |

| MP3022 | Full-Time (Selec-Trac) | ATF+4 | 30k regardless of use |

The MP3022 uses a clutch pack for full-time 4WD on pavement. That clutch sheds material over time, contaminating the fluid and causing shudder. Change it at 30k, no exceptions.

Factory-new MP3022 units often leave the plant low on fluid. Check the fill plug level on any new Wrangler with full-time 4WD.

Axle Service: Water Is Your Enemy

Your Dana axles need attention, especially after water crossings.

Differential Fluid Specs

| Axle | Position | Fluid | Capacity | Notes |

|---|---|---|---|---|

| Dana 30 (M186) | Front (Sport/Sahara) | 80W-90 | 1.7 pints | Standard use |

| Dana 44 (M210) | Front (Rubicon) | 80W-90 | 2.18 pints | Wide track |

| Dana 35 (M200) | Rear (Sport/Sahara) | 80W-90 | 2.43 pints | LSD needs additive |

| Dana 44 (M220) | Rear (Rubicon) | 80W-90 or 75W-140 | 3.02 pints | Use 75W-140 for towing |

If you tow or drive in high heat, upgrade the rear to 75W-140 synthetic to prevent thermal breakdown.

After deep water fording (covering the breather tubes), change axle fluid immediately. Water emulsifies gear oil and destroys its ability to protect ring and pinion gears.

Death Wobble Prevention: Torque Is Everything

Death Wobble isn’t caused by your steering stabilizer—it’s caused by loose components letting the front axle oscillate.

The Inspection Protocol

Track bar: This locates your axle side-to-side. Loose bolts equal violent wobble. Check torque every 20,000 miles. Torque spec is 110 ft-lbs.

Ball joints: JL ball joints use plastic internal liners. Heavy tires (35″+) wear them fast. Check for vertical play.

Control arms: Loose arms allow caster angle changes during oscillation. Lower front bolt torque: 103 ft-lbs + 145°.

A leaking steering stabilizer can mask wobble temporarily but doesn’t cause it. Fix the root cause (track bar, ball joints) instead of band-aiding with a new stabilizer.

Your Maintenance Timeline: What to Do When

Here’s the actual schedule that keeps your Wrangler running past 150,000 miles.

Every 5,000–8,000 Miles

- Change engine oil and filter (correct spec for your engine)

- Rotate tires (use 5-tire rotation with full-size spare)

- Diesel only: Drain fuel water separator, top off DEF, check fuel filter

- 4xe only: Check HV coolant reservoir level

Every 15,000–20,000 Miles

- Replace cabin air filter

- Check track bar and control arm bolt torque

- Inspect front driveshaft CV boot (common tear on lifted Jeeps)

- Inspect brakes (4xe: clean caliper slide pins—they seize from lack of use)

Every 30,000 Miles

- 4xe only: Replace spark plugs (mandatory)

- Change transfer case fluid (especially MP3022 models)

- Inspect/change manual transmission fluid if towing

- Inspect axle fluid (change if you’ve done water crossings)

Every 60,000 Miles

- Replace spark plugs (standard 2.0L turbo)

- Change transfer case fluid (all models)

- Change automatic transmission fluid (pan replacement required)

- Inspect drive belt for glazing or cracks

Every 100,000 Miles

- Replace spark plugs (3.6L V6—requires intake manifold removal)

- Flush and replace engine coolant (use OAT MS-90032 only)

- Flush HV loop coolant (4xe models)

- Replace PCV valve (prevents rear main seal leaks from crankcase pressure)

The Fluid Cheat Sheet You Need

Keep this handy when you’re ordering parts:

Engine Oil

- 3.6L V6: 0W-20 synthetic (MS-6395)

- 2.0L/4xe: 5W-30 synthetic (MS-13340)

- 3.0L Diesel: 5W-40 synthetic (MS-12991)

Coolant: OAT purple/red (MS-90032), Part #68163848AB

Transmission: Mopar 8&9 Speed ATF, Part #68218925AA

Transfer Case: ATF+4 (MS-9602)

Axles: 80W-90 GL-5 (standard), 75W-140 GL-5 (towing/high heat)

The Bottom Line on Your Jeep Wrangler Service Schedule

Think of your Wrangler like industrial equipment, not a grocery-getter. The solid axles, turbocharged engines, and hybrid systems don’t forgive neglect.

The 3.6L V6 needs clean oil to protect VVT components and prevent oil cooler housing failure. The 2.0L turbo and 4xe demand correct viscosity and those 30k spark plugs. The EcoDiesel lives or dies by fuel system cleanliness—clean filters, water separation, and frequent oil changes.

For every model, suspension torque specs prevent Death Wobble. Skip them and you’re in for a rough ride (literally).

Stick to the severe duty intervals. Your Wrangler will thank you by hitting 150k miles without major drama—and holding its value when it’s time to trade up.