Ever wondered what makes Corvette Z06 and Camaro Z28 owners grin like they know something you don’t? It’s what’s under the hood – the legendary LS7 engine. This hand-built 427-cubic-inch beast is one of GM’s most impressive naturally aspirated V8s ever created. If you’re curious about what makes this engine special, you’re in the right place. We’ll break down everything from its basic specs to the engineering details that make gearheads weak in the knees.

What is the LS7 Engine?

The LS7 is a 7.0-liter (427 cubic inches) naturally aspirated V8 engine built by General Motors between 2006 and 2015. It’s not just any engine – it’s a hand-built masterpiece assembled by a single technician at GM’s Performance Build Center in Wixom, Michigan.

This powerplant sits in the Generation IV small-block V8 family, but don’t let the “small-block” label fool you. With 505 horsepower and 470 lb-ft of torque in stock form, there’s nothing small about its performance. The LS7 represents the largest displacement engine in the LS family and was reserved for GM’s most elite performance vehicles.

LS7 Engine Basic Specifications

Let’s start with the fundamental specs before diving deeper:

| Specification | Detail |

|---|---|

| Displacement | 7.0L (427 cubic inches) |

| Horsepower | 505 hp @ 6,300 rpm |

| Torque | 470 lb-ft @ 4,800 rpm |

| Block Material | Aluminum |

| Cylinder Head Material | Aluminum |

| Compression Ratio | 11.0:1 |

| Redline | 7,000 rpm |

| Production Years | 2006-2015 |

What makes these numbers even more impressive is that they’re achieved without turbochargers or superchargers – this is pure, naturally aspirated American muscle at its finest.

LS7 Engine Block Details

The foundation of any great engine starts with the block, and the LS7’s is something special:

The LS7 block is cast from aluminum, making it significantly lighter than traditional iron blocks while maintaining impressive strength. With a 4.125-inch (104.8mm) bore and 4.0-inch (101.6mm) stroke, it achieves its massive 7.0L displacement while staying within the traditional small-block architecture.

Don’t think this aluminum construction means compromised durability. The LS7 block features:

- Six-bolt main bearing caps (instead of the typical four) for superior strength

- Doweled, billet steel main caps for exceptional rigidity

- Pressed-in steel cylinder liners to handle the large bore dimensions

- Deck plate honing for precise cylinder dimensions

The block maintains the traditional 4.4-inch (110mm) bore spacing of GM small blocks, tying it to a lineage that dates back to 1955, despite being thoroughly modern in design and execution.

LS7 Rotating Assembly

The heart of the LS7’s impressive performance comes from its precisely engineered rotating assembly:

Crankshaft

The LS7 utilizes a forged steel crankshaft with a 4.0-inch stroke. This forged construction provides superior strength compared to cast cranks, essential for handling the forces generated by the engine’s displacement and high-rpm capability.

Connecting Rods

Here’s where things get exotic. The LS7 uses titanium connecting rods – a material more commonly found in Formula 1 engines than production cars. These titanium rods are:

- Approximately 30% lighter than comparable steel rods

- Incredibly strong despite their reduced weight

- Key to the engine’s ability to rev quickly and reliably

- A significant contributor to the engine’s 7,000 rpm redline

Pistons

The pistons are hypereutectic aluminum with a flat-top design. They feature:

- Valve reliefs to prevent piston-to-valve contact at high rpm

- Anti-friction skirt coating to reduce drag and improve durability

- Full-floating wrist pins for reduced friction

- Low-tension rings to minimize friction while maintaining proper sealing

This combination of lightweight, high-strength components allows the LS7 to rev higher and respond more quickly than you’d expect from an engine of this size.

LS7 Cylinder Heads and Valvetrain

If the block and rotating assembly form the foundation, the cylinder heads are where the magic happens:

Cylinder Heads

The LS7 cylinder heads are engineering marvels in their own right. These CNC-ported, rectangular port heads feature:

- 270cc intake runners (massive by production engine standards)

- Fully CNC-machined combustion chambers and ports

- 70cc combustion chambers creating an 11.0:1 compression ratio

- Straight, large-diameter intake ports for exceptional airflow

Valves

The valve sizes are equally impressive:

- 2.20-inch (56mm) titanium intake valves

- 1.61-inch (41mm) sodium-filled exhaust valves

The use of titanium for the intake valves reduces valve train mass by about 21 grams per valve. This reduced weight allows for more aggressive cam profiles without valve float at high rpm. The sodium-filled exhaust valves help dissipate heat, critical for a high-performance naturally aspirated engine.

Camshaft and Valvetrain

The LS7 camshaft specs reflect its high-performance intentions:

- Hydraulic roller design

- 211/230-degree duration at 0.050-inch lift

- 0.591/0.591-inch valve lift

- 120.5-degree lobe separation angle

- 1.8:1 ratio rocker arms

This aggressive cam profile, combined with the 1.8-ratio rocker arms, creates significant valve lift without requiring an overly aggressive base circle on the camshaft, helping maintain reliability.

LS7 Oiling System

A unique feature of the LS7 is its racing-derived dry-sump oiling system. Unlike conventional wet-sump systems where oil is stored in the oil pan, the LS7’s system includes:

- A remote 8-quart oil reservoir

- A 6-stage scavenge pump to pull oil from the crankcase

- A pressure pump to circulate oil through the engine

- An oil cooler for temperature management

This system provides several advantages:

- Consistent oil pressure during high-g cornering, acceleration, and braking

- Reduced risk of oil starvation during aggressive driving

- Lower crankcase pressure, reducing parasitic power loss

- Improved oil cooling capacity

- Lower center of gravity due to the shallow oil pan design

This racing-derived feature is rarely found in production vehicles and highlights GM’s commitment to making the LS7 a true track-capable engine.

LS7 Induction and Fuel System

The LS7’s breathing capacity is supported by its robust induction and fuel systems:

Intake Manifold

The low-profile composite intake manifold features:

- Eight equal-length runners for consistent cylinder-to-cylinder distribution

- A 90mm throttle body (larger than standard LS engines)

- Tuned runner length for optimal mid-range torque

- A streamlined design to fit under the low hood lines of the Corvette Z06

Fuel System

The LS7 uses a sequential multi-port fuel injection system with:

- High-flow injectors rated at 45 pounds per hour

- Returnless fuel rail design

- Integrated fuel pressure regulator

- Electronic throttle control (drive-by-wire)

The combination of these systems allows the LS7 to deliver exceptional throttle response while maintaining emissions compliance and reasonable fuel economy when cruising.

LS7 Vehicles and Applications

The LS7 was reserved for GM’s most elite performance vehicles:

- 2006-2013 Chevrolet Corvette Z06

- 2013 Corvette 427 Convertible

- 2014-2015 Chevrolet Camaro Z/28

- HSV W427 (Australia)

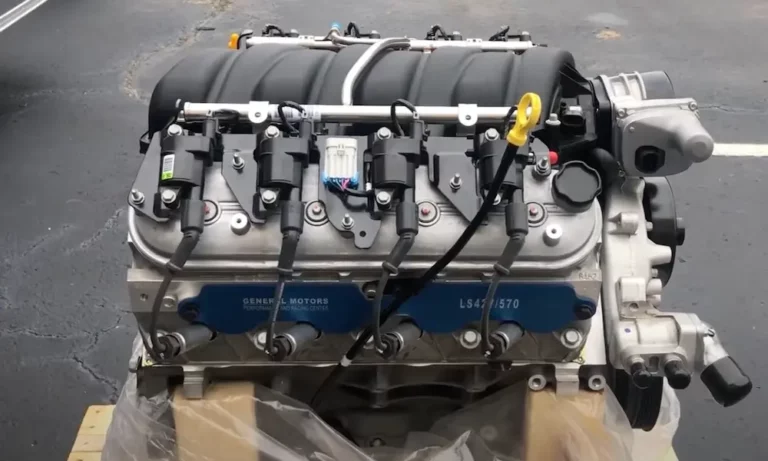

It was also offered as a crate engine for custom builds and racing applications. In 2020, GM introduced an evolution called the LS427/570 crate engine, producing 570 horsepower and 540 lb-ft of torque.

Sadly, both the LS7 and LS427/570 crate engine programs were discontinued in January 2022, marking the end of an era.

LS7 Performance Potential

While impressive in stock form, the LS7 has tremendous potential for additional performance:

In stock form, the LS7 delivers 505 horsepower and 470 lb-ft of torque. However, aftermarket builders have extracted much more, with some naturally aspirated builds exceeding 650 horsepower while maintaining streetability.

Common upgrades include:

- Aftermarket camshafts with more aggressive profiles

- Ported cylinder heads for increased airflow

- Higher compression pistons

- Aftermarket intake manifolds

- Larger throttle bodies

- Headers and exhaust upgrades

- Engine management tuning

With forced induction (supercharger or turbocharger), power levels of 800+ horsepower are achievable while maintaining reasonable reliability.

LS7 Known Issues and Reliability

Despite its high-performance nature, the LS7 is generally reliable when properly maintained. However, there are a few known issues to be aware of:

Valve Guide Wear

Some early LS7 engines experienced premature valve guide wear. This was addressed by GM with updated guides, and aftermarket solutions are available for affected engines.

Piston Ring Seating

The LS7’s cylinder bore finish requires proper break-in to ensure the rings seat correctly. Failure to follow proper break-in procedures can lead to increased oil consumption.

Oil Consumption

Related to the above, some LS7 engines consume oil at a higher rate than typical production engines. This isn’t necessarily problematic as long as oil levels are monitored, but it can be concerning for owners used to engines that use no oil between changes.

Lifter Failure

Like other LS family engines, the LS7 can experience occasional lifter failures. This is relatively rare but should be on owners’ radar.

With proper maintenance and careful operation during break-in, the LS7 can be a remarkably reliable engine despite its high-performance capabilities.

LS7 Historical Significance

The LS7 represents a high-water mark in naturally aspirated V8 engine development. Its creation in the mid-2000s came at a pivotal time in automotive history – just before emissions regulations and fuel economy concerns would push manufacturers toward smaller-displacement, forced-induction engines.

Interestingly, the “LS7” designation has historical significance in GM’s engine heritage. The name was previously used for a high-performance 454-cubic-inch Big Block V8 intended for Corvettes in the early 1970s, though that engine never officially made it to production.

The modern LS7 stands as perhaps the ultimate evolution of the traditional naturally aspirated pushrod V8 before turbocharging, direct injection, and variable valve timing became ubiquitous in performance engines.

LS7 vs. Other LS Engines

How does the LS7 compare to its LS-family siblings? Here’s a quick comparison of some key LS engines:

| Engine | Displacement | Horsepower | Torque | Key Features |

|---|---|---|---|---|

| LS1 | 5.7L (346ci) | 305-350 hp | 350-365 lb-ft | The original modern LS engine |

| LS2 | 6.0L (364ci) | 400-405 hp | 400-405 lb-ft | Gen IV architecture, improved heads |

| LS3 | 6.2L (376ci) | 426-436 hp | 420-428 lb-ft | Rectangular ports, larger valves |

| LS7 | 7.0L (427ci) | 505 hp | 470 lb-ft | Dry sump, titanium rods, CNC heads |

| LSA | 6.2L (376ci) | 556-580 hp | 551-556 lb-ft | Supercharged LS3 derivative |

| LS9 | 6.2L (376ci) | 638 hp | 604 lb-ft | Supercharged, more boost than LSA |

| LT1 | 6.2L (376ci) | 455-460 hp | 455-465 lb-ft | Gen V, direct injection, VVT |

While the supercharged LSA and LS9 engines produce more power, the LS7 remains the pinnacle of naturally aspirated LS development and offers a driving experience that forced-induction engines simply can’t match – instant throttle response, linear power delivery, and a glorious sound all the way to its 7,000 rpm redline.

Why the LS7 Remains Legendary

Fifteen years after its introduction, the LS7 remains a benchmark for naturally aspirated performance. Its combination of substantial displacement, advanced materials, racing-derived features, and hand-built quality created an engine that delivers both impressive numbers and an exceptional driving experience.

The LS7’s heritage as a Le Mans-inspired racing engine translated to road cars means it delivers a special character that even modern, more powerful engines struggle to match. Its linear power delivery, immediate throttle response, and spine-tingling soundtrack create an emotional connection that turbocharged engines – even those producing more power – often lack.

For enthusiasts seeking to build a high-performance vehicle with the soul of a naturally aspirated V8, the LS7 remains a prime candidate, with extensive aftermarket support and proven reliability when properly built and maintained.

The fact that GM won’t be making any more of them only adds to their mystique and desirability among collectors and enthusiasts alike.